An acoustic emission monitoring system

A monitoring system, acoustic emission technology, applied in the direction of measuring devices, using ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of prolonging the project progress, acoustic emission detection limit, long period, etc., to ensure the coupling effect and achieve repeated use , enhanced stability and the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

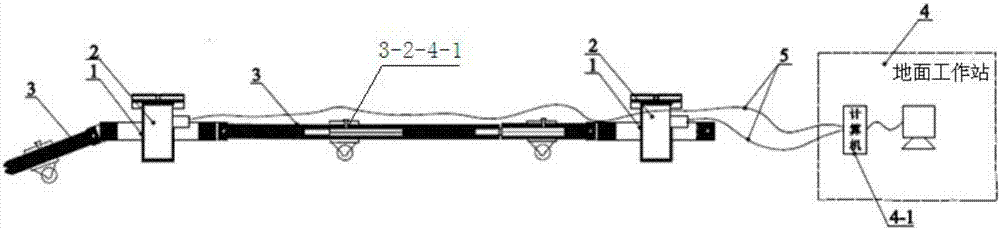

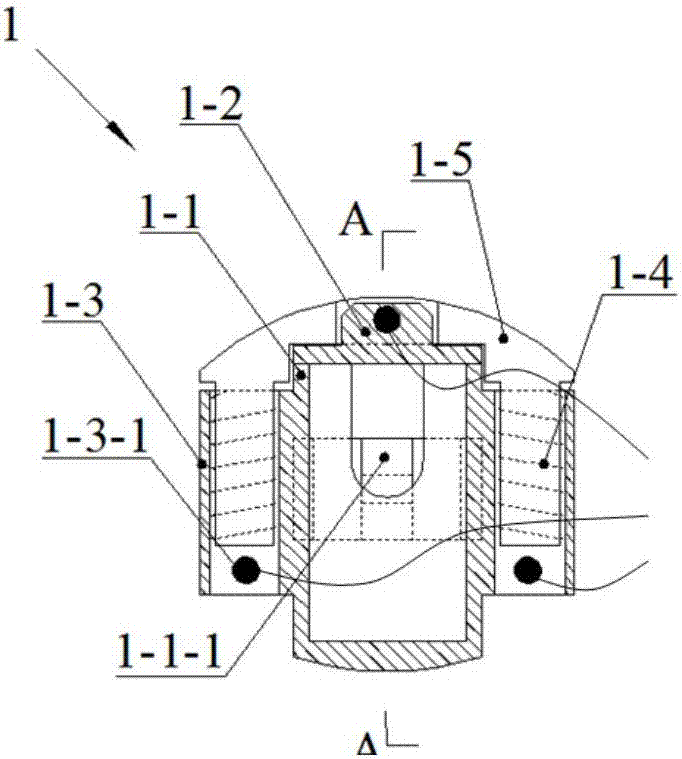

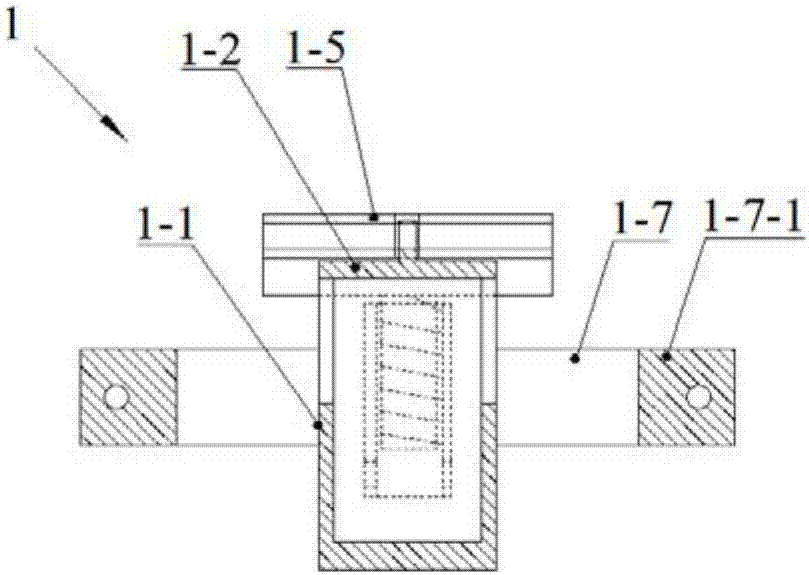

[0051] The acoustic emission monitoring system provided by this embodiment is as figure 1 As shown, it includes an acoustic emission sensor and a ground workstation 4, the acoustic emission sensor is used to be installed in the borehole 6 of the monitored rock mass 7, and the received monitoring signal is transmitted to the ground workstation 4 through a cable 5, and the ground workstation 4 The computer 4-1 processes and displays the monitoring signal from the emission sensor; the acoustic emission sensor is composed of the acoustic emission probe 2, the probe installation mechanism and the transmission mechanism 3 that transmits the installation mechanism equipped with the acoustic emission probe to the set position in the borehole Composition; there are two probe installation mechanisms 1 and two acoustic emission probes 2.

[0052] Such as Figure 9 , Figure 10 As shown, the above-mentioned acoustic emission probe 2 is a cylindrical structure with a cable connector 2-1 ...

Embodiment 2

[0066] The acoustic emission monitoring system provided by this embodiment, such as Figure 19 As shown, it includes an acoustic emission sensor and a ground workstation 4, the acoustic emission sensor is used to be installed in the borehole 6 of the monitored rock mass 7, and the received monitoring signal is transmitted to the ground workstation 4 through a cable 5, and the ground workstation 4 The computer 4-1 processes and displays the monitoring signal from the emission sensor; the acoustic emission sensor is composed of the acoustic emission probe 2, the probe installation mechanism and the transmission mechanism 3 that transmits the installation mechanism equipped with the acoustic emission probe to the set position in the borehole Composition; the number of the probe installation mechanism 1 and the acoustic emission probe 2 is three.

[0067] The structures of the probe installation mechanism 1 and the acoustic emission probe 2 provided in this embodiment are the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com