Long and thin bore diameter and cylindricity measurement method based on dual-sensor error separation

A dual-sensor, inner hole diameter technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of complex realization principles and devices, inability to adapt to inner holes, and affect measurement accuracy, and achieve reduced operation complexity, strong adaptability and flexibility nature, avoiding the effect of the calculation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described in detail below in conjunction with the drawings:

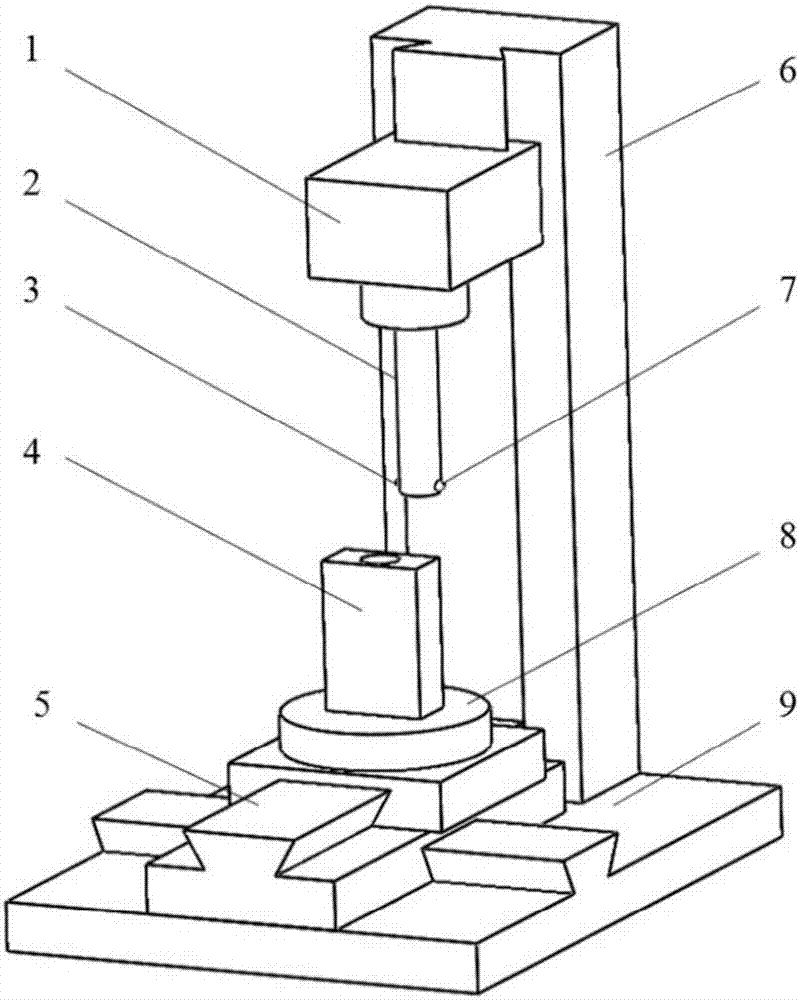

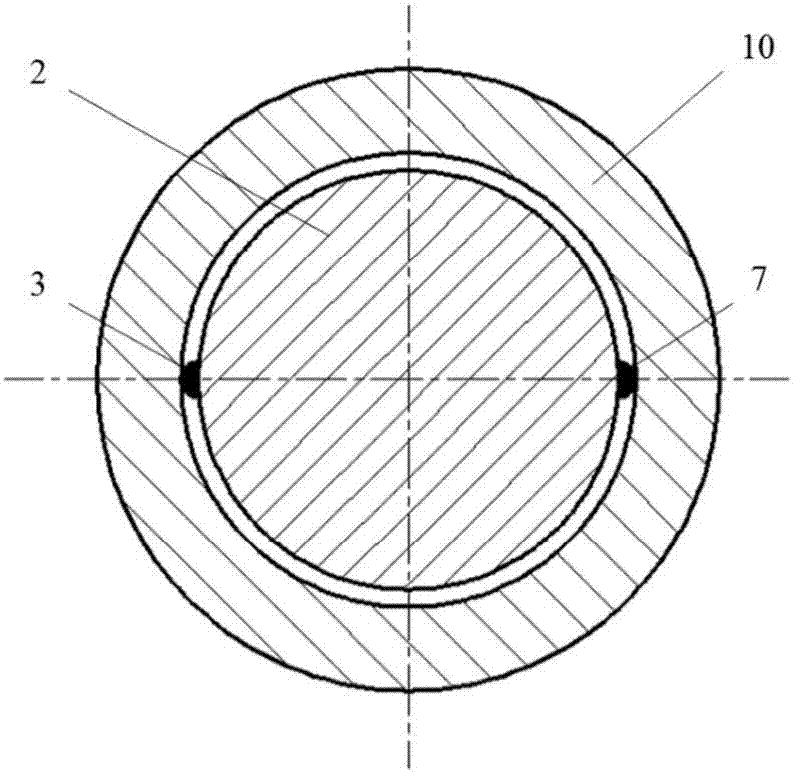

[0064] Such as figure 1 As shown, the device implemented in the present invention includes a vertical lifting mechanism 1, a dual sensor probe 2, an electronic displacement sensor 3 and 7, a workpiece to be tested 4, an X-direction guide 5, a Z-direction guide 6, a turntable 8 and a base 9. . The Z-direction guide 6 is fixedly installed on the base 9. The vertical lifting mechanism 1 is embedded on the Z-direction guide 6 and moves up and down along the Z-direction guide 6. The lower end of the vertical lifting mechanism 1 is equipped with a double sensor probe 2, double Electronic displacement sensors 3 and 7 are installed symmetrically on both sides of the lower end of the sensor probe 2, and the electronic displacement sensors 3 and 7 are symmetrically arranged; the base 9 itself is provided with a Y-direction rail, and the X-direction rail 5 is embedded on the Y-directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com