Preparation method of electron backscatter diffraction sample with alloy strip thickness section

A technology of electron backscattering and sample preparation, which is applied in the preparation of test samples, sampling, measuring devices, etc., can solve the problems that it is difficult to obtain electron backscattering diffraction samples, and achieve improved calibration rate, good conductivity, The effect of good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

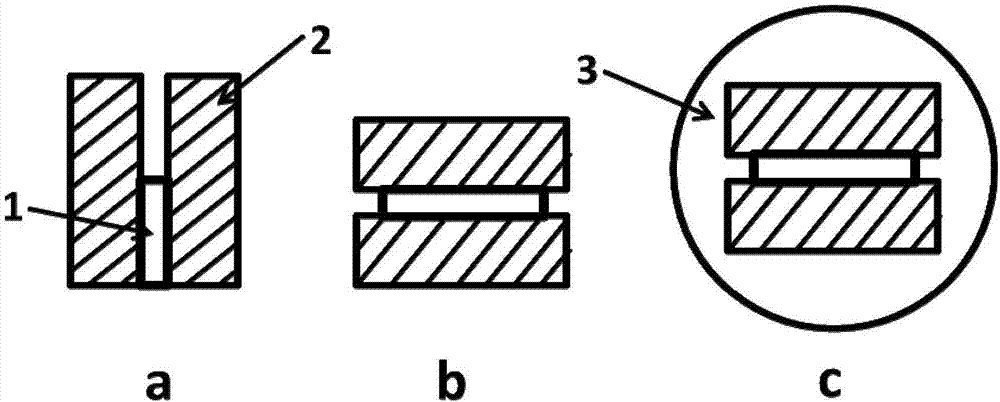

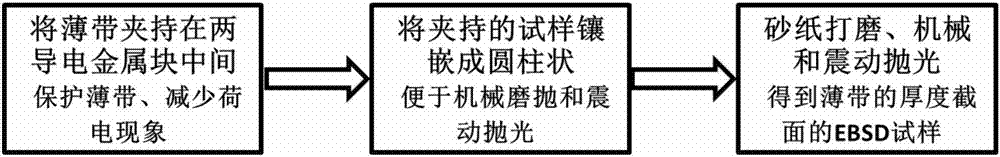

[0030] This embodiment is used for the preparation of the electron backscatter diffraction sample of the thickness section of the NiMnInCo alloy ribbon with a thickness of 40 microns, and the specific implementation steps are as follows:

[0031] 1. Select a complete thin strip with a straight section and no gap.

[0032] 2. Select two rectangular conductive metal blocks with the same length as the selected thin strip and the same hardness as the thin strip, so that the thickness of the alloy thin strip to be analyzed is horizontally downward and consistent with the plane of the two conductive metal blocks. The thin strip is clamped between two conductive metal blocks.

[0033] 3. Clamp the two conductive metal blocks with tweezers, make the conductive metal block clamp the thin alloy ribbon, and then drop 1-2 drops of 502 glue between the gaps on the back of it, and blow dry quickly to make the two conductive metal blocks and the alloy thin The straps are fixed together.

[0034] 4....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com