Fast measuring device and method for molecular weight of chitosan

A technology of chitosan and molecular weight, applied in the measurement of DC flow characteristics, etc., can solve the problems of inconvenient work, cumbersome operation, easy damage to glass tubes, etc., and achieve the effect of improving accuracy, simplifying operation and convenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

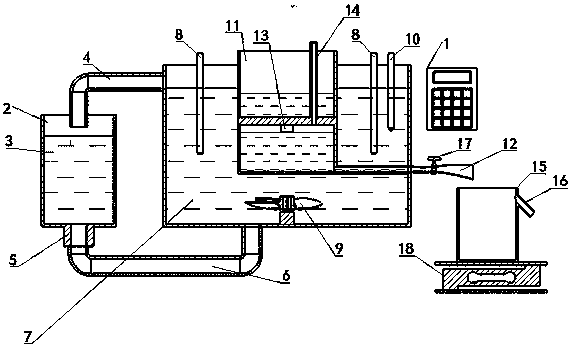

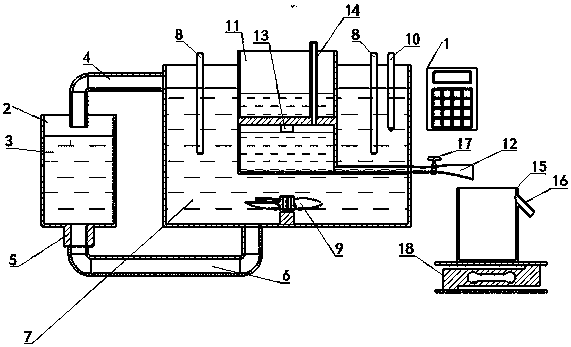

[0055] Since the accompanying drawings are used to provide a further understanding of the present invention, the schematic embodiments of the present invention and their descriptions are used to explain the present invention, and do not constitute an improper limitation of the present invention.

[0056] Attached below figure 2 To further illustrate the specific implementation of the present invention.

[0057] attached figure 2 The device for rapidly measuring the molecular weight of chitosan includes a constant temperature tank 7 and a liquid storage tank 11 arranged in the constant temperature tank 7, an ice pack tank 2 arranged side by side with the constant temperature tank 7, and a single-chip microcomputer 1. The liquid storage tank 11 includes two upper and lower cavities communicated with each other through the water level valve 13. The lower cavity is provided with a vent pipe 14 that communicates with the outside atmosphere. 12. A valve 17 is provided on the cap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com