Test device for simulating diffusion and migration of in-situ pyrolysis pollutants in underground water

A technology of in-situ pyrolysis and test equipment, applied in measuring equipment, liquid dispersion analysis, instruments, etc., can solve problems such as heavy metals, organic pollutants entering, large phase difference, groundwater pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

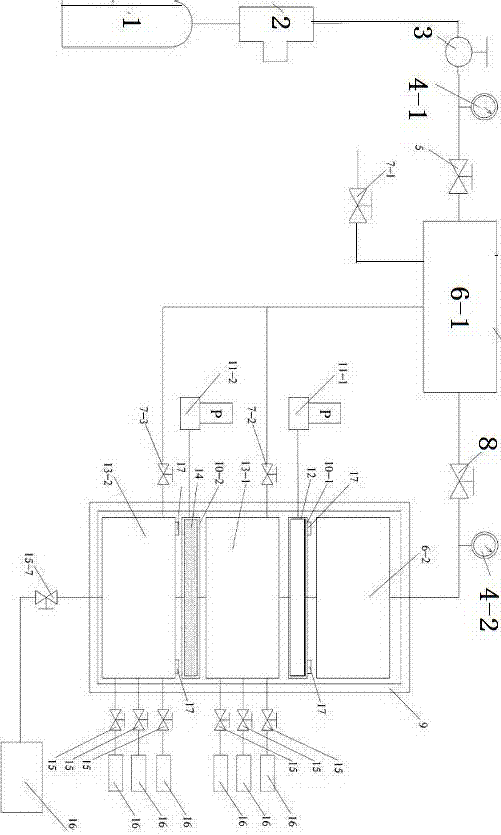

[0021] Implementation mode 1: Simulate the diffusion and migration of oil shale in-situ pyrolysis pollutants in groundwater

[0022] The test device in this embodiment adopts the above-mentioned test device for simulating the diffusion and migration of in-situ pyrolyzed pollutants in groundwater.

[0023] The specific implementation steps are as follows:

[0024] 1. Put the pyrolysis oil shale test piece and the water-permeable rock formation test piece with a size of Φ400×50mm into the pyrolysis rock formation support platform 12 and the adjacent water-permeable formation support platform 14 respectively, and use fastening bolts 17 to load the pyrolysis formation rock formation. The platform 12 is sealed, and the adjacent permeable rock formation platform 14 is sealed.

[0025] 2. The first water replenishment valve 7-1 is opened, the second water replenishment valve 7-2 is opened, the third water replenishment valve 7-3 is opened, and the water inlet valve 8 is opened, so t...

Embodiment approach 2

[0031] Implementation mode 2: Simulating the diffusion and migration of lignite in situ pyrolysis pollutants in groundwater

[0032] The test device of this embodiment adopts the above-mentioned test device for simulating the diffusion and migration of in-situ pyrolysis pollutants in groundwater, which can meet the requirements of simulating the diffusion and migration of lignite in-situ pyrolysis pollutants in groundwater. and the permeable rock formation test piece are placed in the carrier, sealed, and the equipment is filled with water. After the temperature of the thermostat reaches the set value and stabilizes for 30 minutes, apply axial pressure, confining pressure and water pressure to the test piece, and open the bottom drain valve 15. Make it flow at the same speed as the groundwater flow. After that, the drain valve on the right side was opened regularly to collect the polluted liquid at different locations, the composition and concentration of the polluted liquid w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com