Turbulence prevention and scale reduction structure and optical liquid concentration test device

A liquid concentration and protective device technology, applied in the field of sensors, can solve the problems of low reliability, inaccurate measurement, and low accuracy of urea liquid concentration measurement results, and achieve the effect of guaranteeing life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

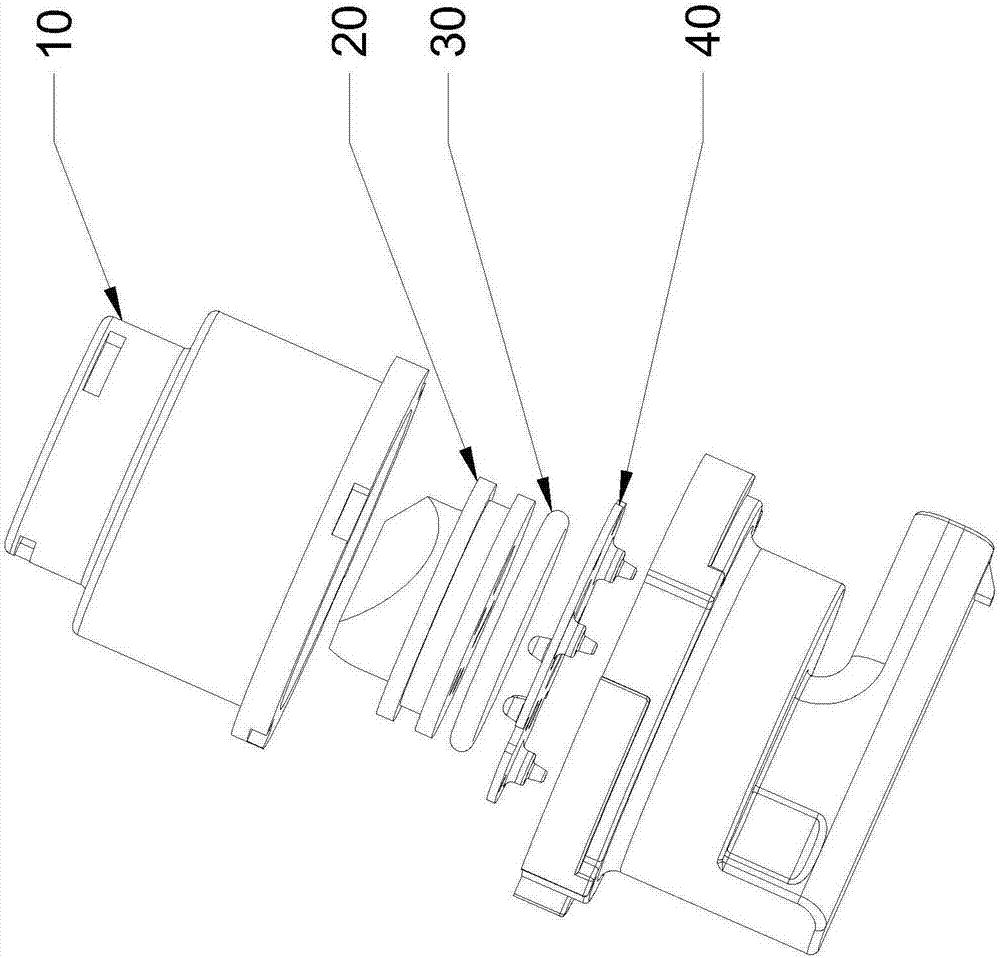

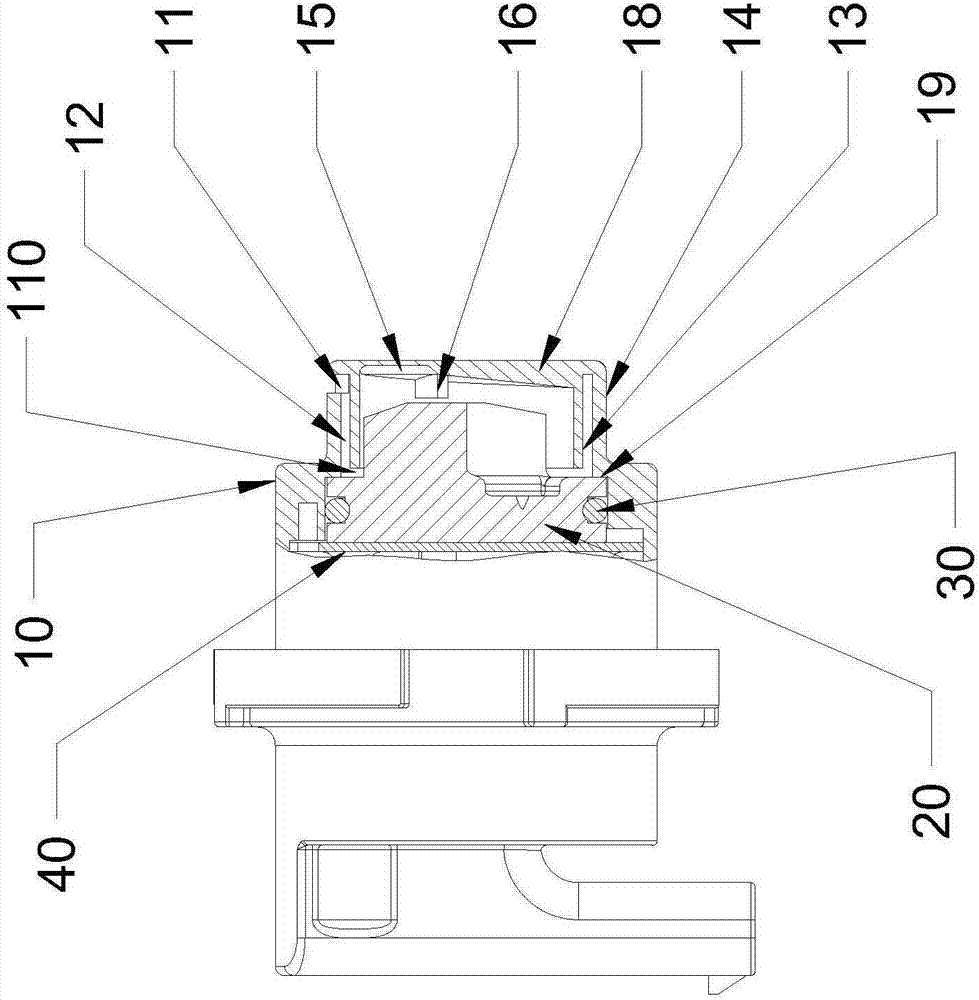

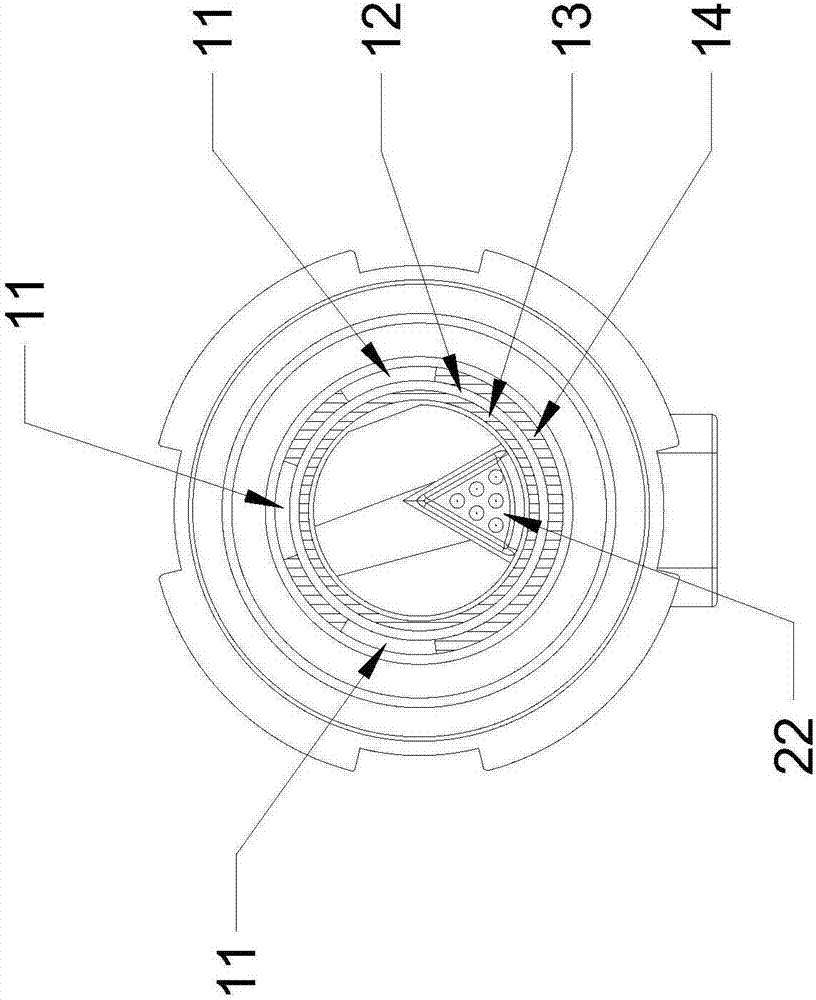

[0092] Such as Figure 1 to Figure 3 As shown, an optical liquid concentration sensor includes a turbulence shield 10 , an optical component 20 of a sensor device, a sealing ring 30 , and an assembly bracket 40 . The turbulence shield 10 is connected to the assembly bracket 40 through fasteners. The optical component 20 is locked by the assembly bracket through the annular platform 19 of the outer ring column 14 and the limiting platform 25 of the optical component in the turbulence shield 10 .

[0093] The turbulent flow shield 10 is designed as an integrated engineering plastic part, and its liquid inlet 11 and ring post gap 12 are molded at one time. Specifically, the liquid inlet 11 is designed at the end far away from the tested liquid testing area of the sensor. The above-mentioned optical component 20 and the turbulence shield 10 are locked by fasteners. After locking, the inner ring column 13 of the turbulence shield and the limiting platform 25 of the optical comp...

Embodiment 2

[0099] Such as Figure 1 to Figure 3 As shown, an optical liquid concentration sensor includes a turbulence shield 10 , an optical component 20 of a sensor device, a sealing ring 30 , and an assembly bracket 40 . The turbulence shield 10 is connected to the assembly bracket 40 through fasteners. The optical component 20 is locked by the assembly bracket through the annular platform 19 of the outer ring column 14 and the limiting platform 25 of the optical component 20 in the turbulence shield 10 .

[0100] The turbulent flow shield 10 is designed as an integrated engineering plastic part, and its liquid inlet 11 and ring post gap 12 are molded at one time. Specifically, the liquid inlet 11 is designed at the end far away from the tested liquid testing area of the sensor. The above-mentioned optical component 20 and the turbulence shield 10 are locked by fasteners. After locking, the inner ring column 13 of the turbulence shield and the limiting platform 25 of the optical c...

Embodiment 3

[0106] Such as Figure 1 to Figure 3 As shown, an optical liquid concentration sensor includes a turbulence shield 10 , an optical component 20 of a sensor device, a sealing ring 30 , and an assembly bracket 40 . The turbulence shield 10 is connected to the assembly bracket 40 through fasteners. The optical component 20 is locked by the assembly bracket through the annular platform 19 of the outer ring column 14 and the limiting platform 25 of the optical component 20 in the turbulence shield 10 .

[0107] The turbulent flow shield 10 is designed as an integrated engineering plastic part, and its liquid inlet 11 and ring post gap 12 are molded at one time. Specifically, the liquid inlet 11 is designed at the end far away from the tested liquid testing area of the sensor. The above-mentioned optical component 20 and the turbulence shield 10 are locked by fasteners. After locking, the inner ring column 13 of the turbulence shield and the limiting platform 25 of the optical c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com