Composite insulator charged checking device

A composite insulator and inspection device technology, applied in the field of circuit inspection, can solve the problems of incomplete line detection, difficult inspection and detection, and undetectable, and achieve the effects of ensuring quality and performance, improving safety factor, and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

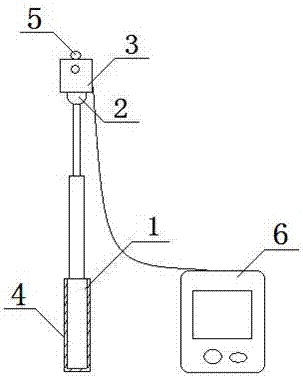

[0017] like figure 1 As shown, a composite insulator live inspection device includes a telescopic rod 1, a universal joint 2, a camera 3, a detection lamp 5, an insulating sleeve 4, and a monitor 6. The upper end of the telescopic rod 1 passes through the universal joint 2 and the camera 3 Connection, the camera 3 is provided with a detection light 5, one side of the camera 3 is connected with the monitor 6, and the lower end of the telescopic rod 1 is connected with the insulating sleeve 4.

[0018] The telescopic rod 1 is composed of a number of branches. The diameter of each branch of the telescopic rod 1 is reduced by a ratio of 0.4 from bottom to top, and the length of the branch is shortened by a ratio of 0.1, which will strengthen the supporting force of the telescopic rod 1 and increase the Large adjustment of the length of the telescopic rod 1 is convenient for use during operation.

[0019] The camera 3 rotates through the universal joint 2, the circumferential rot...

Embodiment 2

[0024] A live inspection device for composite insulators. When the composite insulator circuit needs to be detected, the operator holds the insulating sleeve 4 and adjusts the length of the telescopic rod 1 through the telescopic rod 1 according to the position of the composite insulator circuit. The telescopic rod 1 moves from bottom to top every The diameter of the branch section is reduced by a ratio of 0.2, and the length of the branch section is shortened by a ratio of 0.3 to increase the support force of the telescopic rod 1 and facilitate the expansion and contraction of the telescopic rod 1. When it is stretched to the required length, adjust the angle of the camera 3, and the camera 3 The angle can be adjusted freely through the universal joint 2 to increase the detection area. When detecting the composite insulator circuit, the camera 3 is continuously rotated, and the camera 3 transmits the detection screen to the monitor 6. The operator passes through the customs and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rotation angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com