Adjustable thin plate combination type flex-tensional transducer

A bending-tension transducer and combined technology, which is applied in the direction of instruments and sound-generating devices, can solve the problems of difficult molding of shells, high processing technology requirements, and non-adjustable prestress, and achieves flexible dimensions, convenient hanging and testing, and increased The effect of displacement output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings.

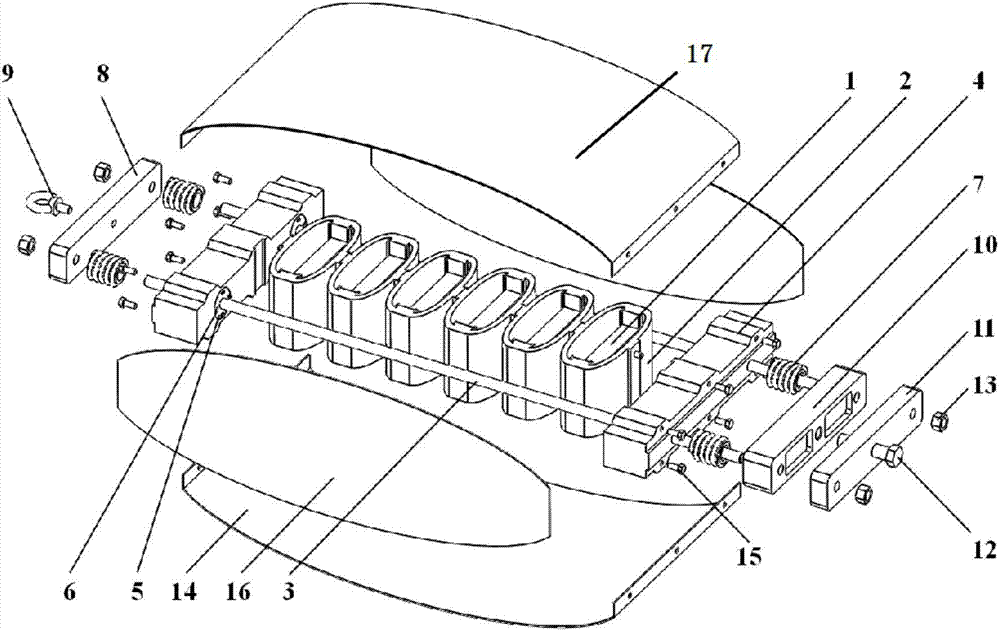

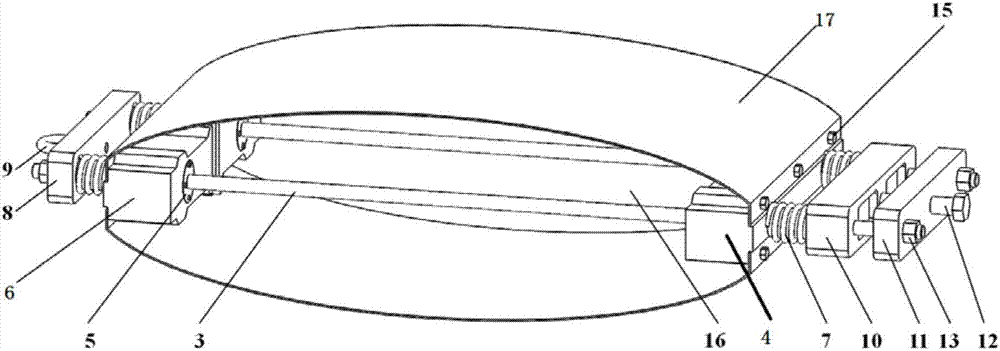

[0029] like figure 1 Shown is a schematic diagram of an exploded structure of an adjustable thin-plate combined flextensional transducer. The present invention includes a flextensional housing, a drive assembly, a left transition block 6, a right transition block 4, and a flextensional housing for adjusting the flextensional housing. Body adjustment device;

[0030] join figure 1 and figure 2 , wherein the flexural shell is a split structure, including an upper thin plate 17 and a lower thin plate 14; the upper thin plate 17 and the lower thin plate 14 are arc-shaped plates formed by bending and forming a wooden mold; the upper thin plate 17 and the lower thin plate 14 are respectively It is fixedly installed on the left transition block 6 and the right transition block 4 through set bolts 15 and forms a space for installing the drive assembly. Such a design is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com