shield conductive path

A technology of conductive paths and shielding tubes, applied in the field of shielded conductive paths, can solve problems such as manufacturing difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

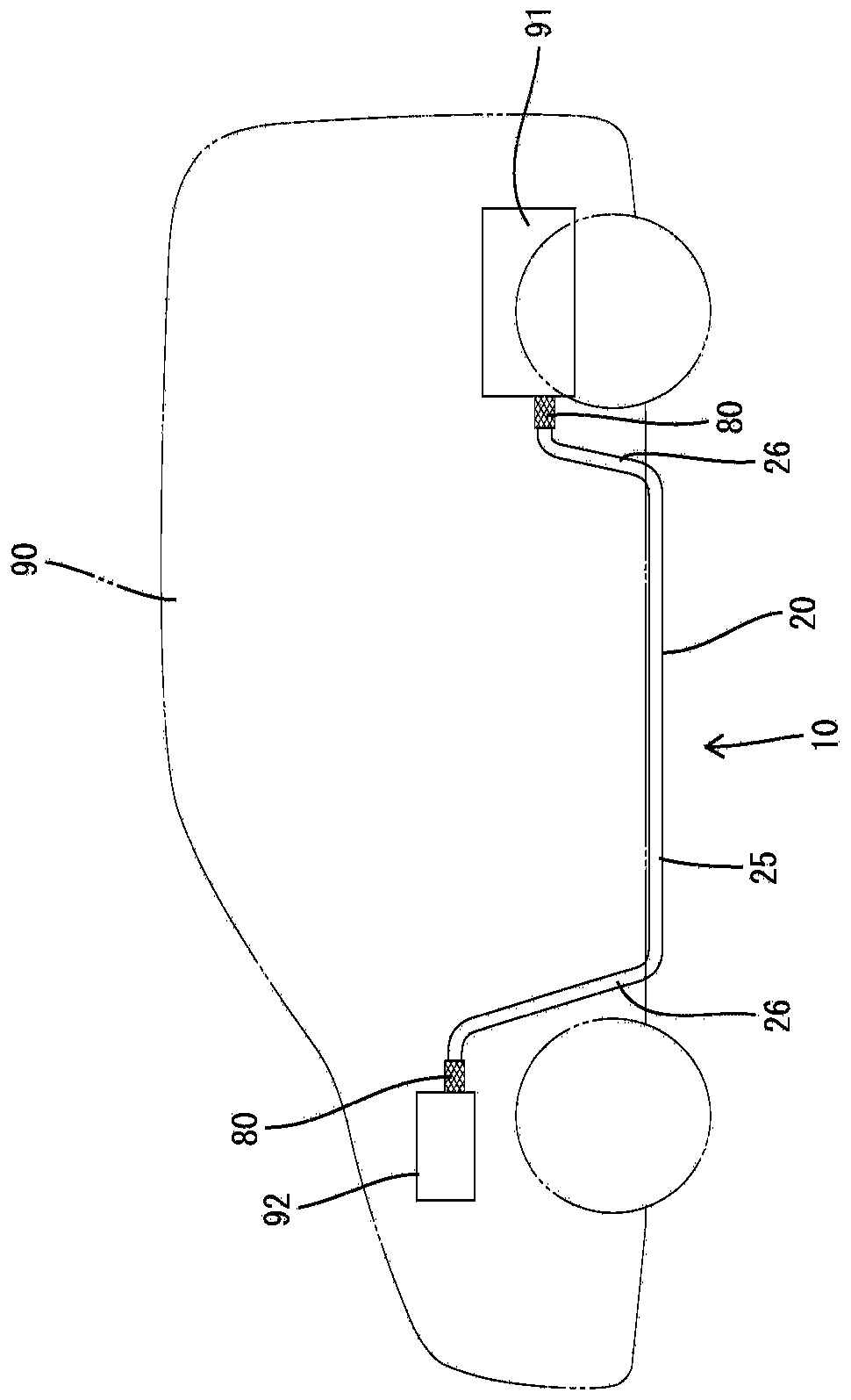

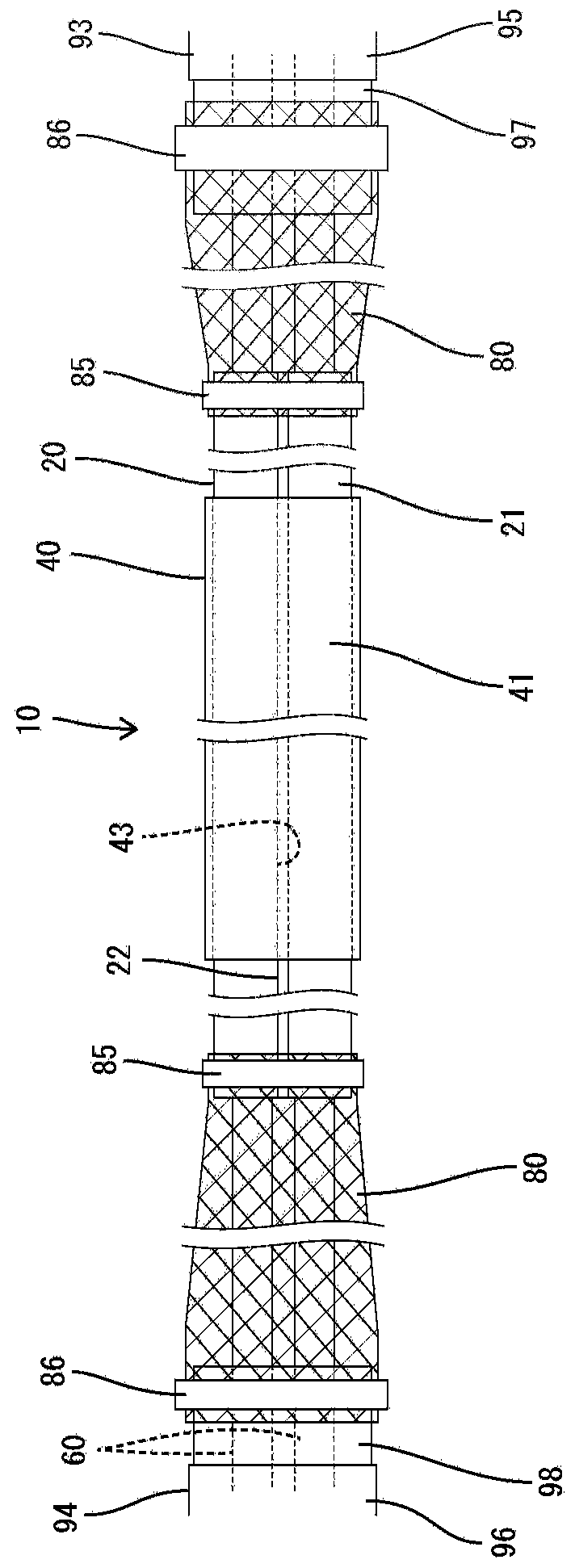

[0021] Below, refer to Figure 1 to Figure 5 Example 1 will be described. Regarding the shielded conductive path 10 of Embodiment 1, in vehicles such as hybrid cars, such as figure 1 As shown, for example, equipment 91 such as a high-voltage battery provided at the rear of the vehicle body 90 should be connected to equipment 92 such as an inverter and a fuse box provided at the front of the vehicle body 90, and wired to the chassis of the vehicle body 90. . In addition, the devices 91 and 92 are accommodated in conductive shielding cases.

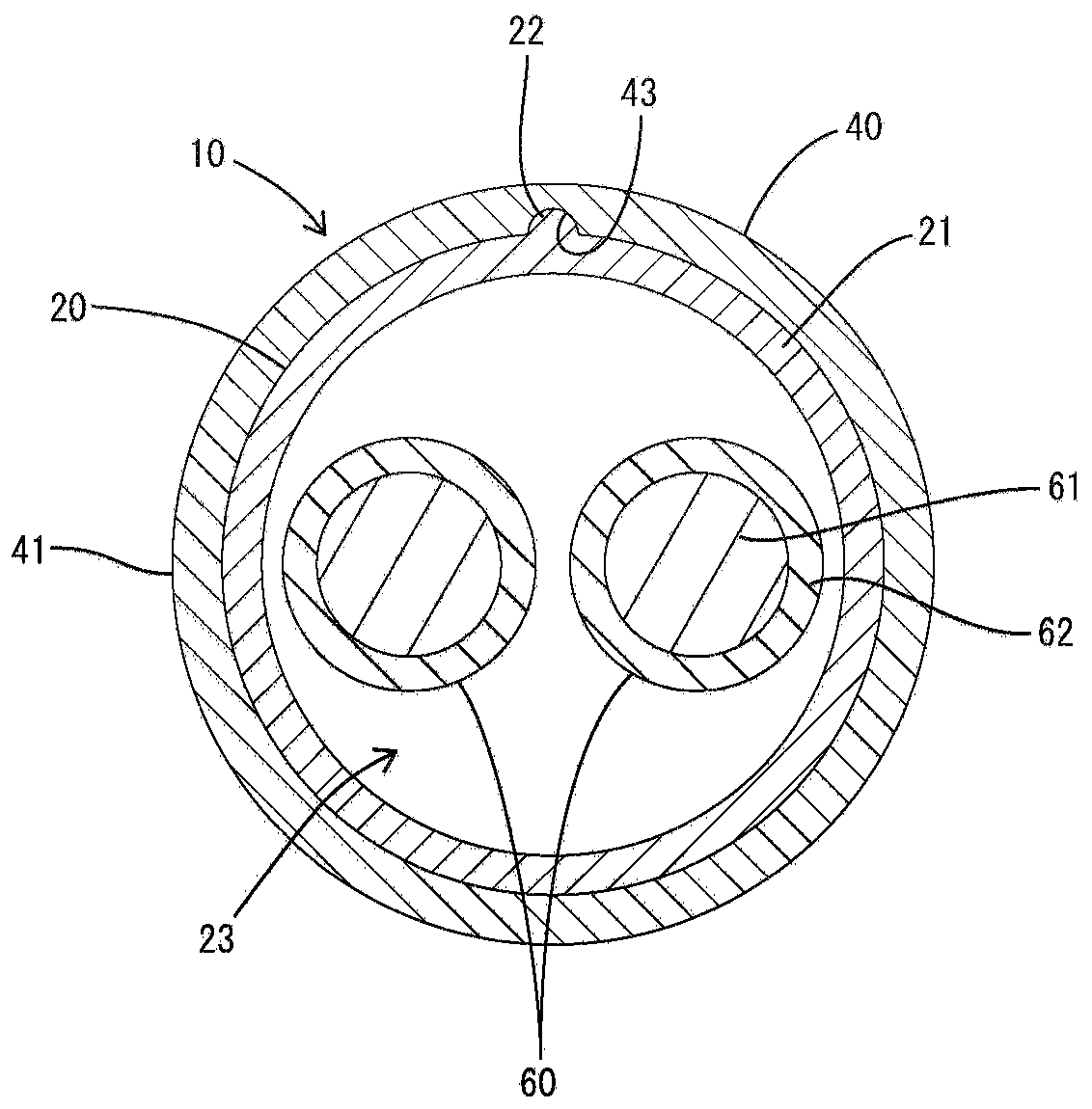

[0022] The shielded conductive path 10 has a plurality of (two in the case of Embodiment 1) electric wires 60 , a shielded tube 20 , and a resin tube 40 separate from the shielded tube 20 .

[0023] Such as image 3 As shown, the electric wire 60 is an unshielded electric wire composed of a conductor 61 (copper, aluminum, etc.) and an insulating resin coating 62 covering the periphery of the conductor 61 . Terminal fittings (not shown)...

Embodiment 2

[0045] Figure 6 ~ Figure 8 Example 2 is shown. In the shielded conductive path 10A of the second embodiment, contrary to the first embodiment, the concave portion 43A is provided on the outer peripheral surface of the shielding tube 20A, and the convex portion 22A is provided on the inner peripheral surface of the resin tube 40A. In other words, in Embodiment 1, the concave portion 43A opens inward and the convex portion 22A protrudes outward, but in the case of Embodiment 2, the concave portion 43A opens outward and the convex portion 22A protrudes inward.

[0046] The concave portion 43A and the convex portion 22A are formed to be able to fit each other, and have the same shape as that of the first embodiment. When the resin tube 40A is assembled to the shield tube 20A, the convex portion 22A of the resin tube 40A fits into the recess 43A of the shield tube 20A, and the resin tube 40A is held circumferentially positioned on the shield tube 20A. This point is also the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com