A three-phase five-column amorphous alloy transformer

An amorphous alloy, three-phase five-column technology, applied in the direction of transformers, fixed transformers, transformer/inductor parts, etc., can solve the problem of low anti-vibration performance, improve anti-vibration performance, shorten service life, and reduce noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

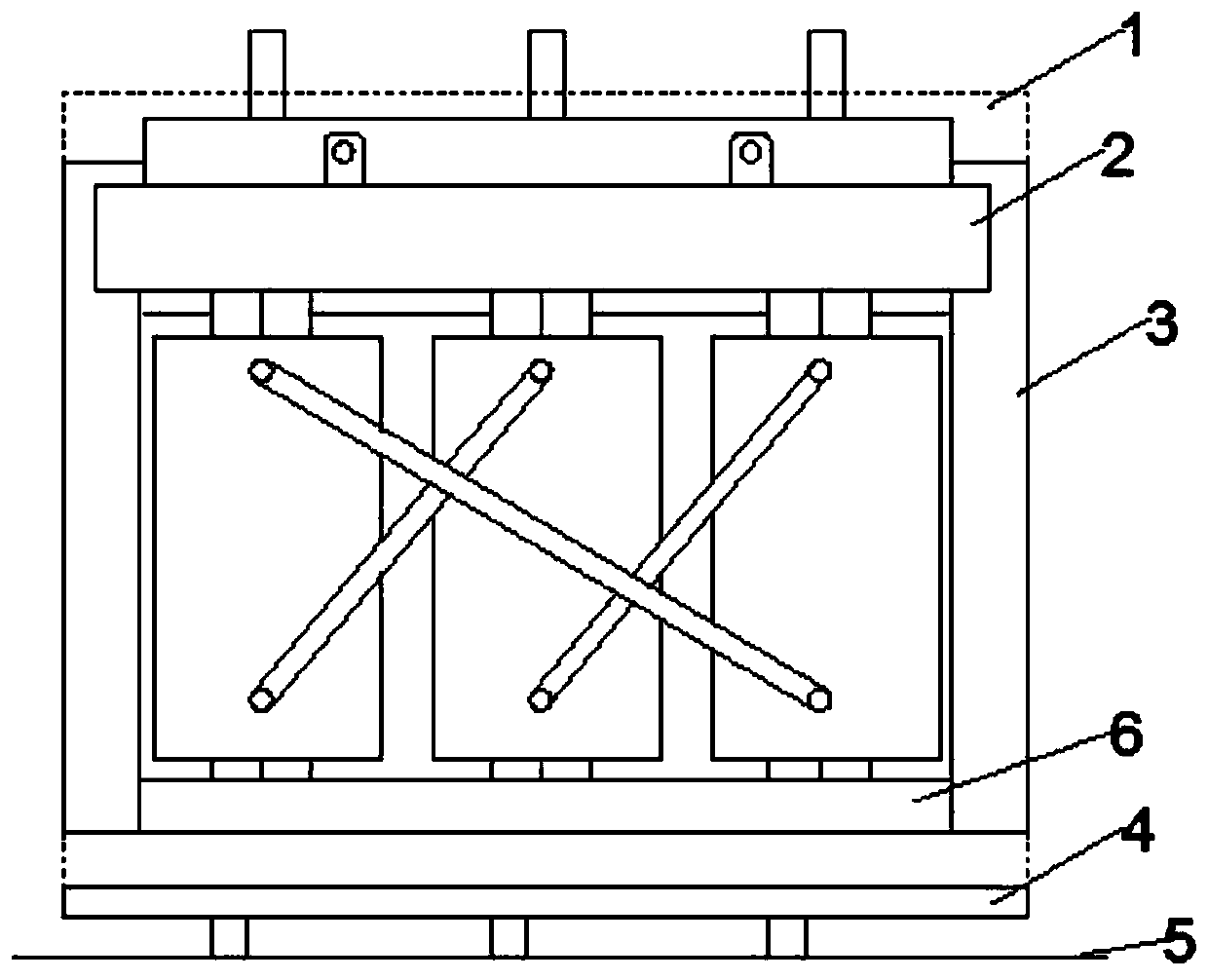

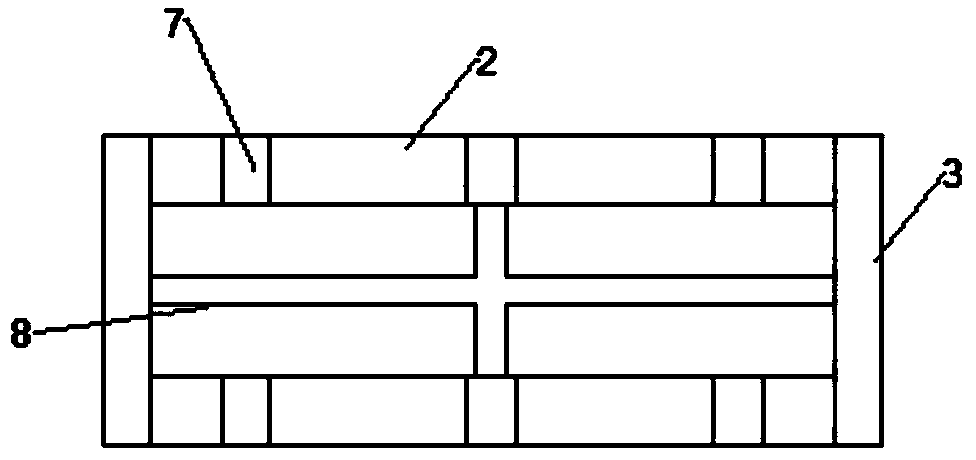

[0030] This embodiment provides a three-phase five-column amorphous alloy transformer, such as figure 1As shown, the three-phase five-column amorphous alloy transformer includes an amorphous alloy, a coil, a clip, a transformer frame 1 and a transformer box 5; the amorphous alloy dry-type transformer adopts a three-phase five-column transformer, and the transformer frame 1 Located in the transformer box 5, the transformer frame 1 supports the overall amorphous alloy dry-type transformer; the amorphous alloy includes an upper iron yoke, a lower iron yoke, and an iron core column arranged between the iron yoke and the lower iron yoke, and the coil is sleeved on The iron core column clamps the amorphous alloy through clamps. The clamps are divided into upper clamp 2, lower clamp 6 and side clamp 3. The upper clamp 2 is fixed above the upper iron yoke by pressing nails and rubber, and the lower clamp Part 6 is also fixed under the lower iron yoke by pressing nails and rubber, and ...

Embodiment 2

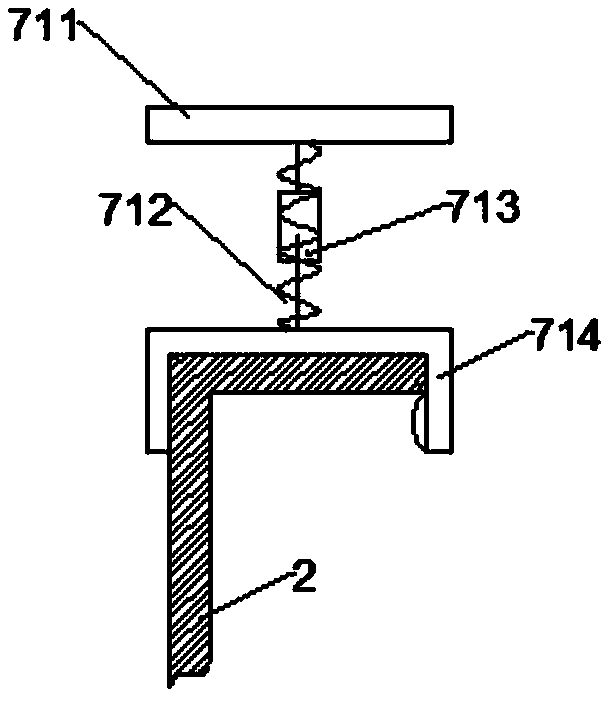

[0034] In order to facilitate the assembly of the reinforcing rib 8 and save assembly time; for example Figure 7 As shown, the reinforcing rib 8 is composed of a first rectangular plate 81 and a second rectangular plate 82, the center position of the first rectangular plate 81 is welded and fixed with the center position of the second rectangular plate 82, and the second rectangular plate 82 is welded and fixed. Both ends of a rectangular plate 81 in the axial direction are provided with a groove A83, and the opening end of the groove A83 faces the bottom of the first rectangular plate 81, and the width of the groove A83 is consistent with the thickness of the upper clamp 2; The square plate 81 is buckled on the top of the upper clamp 2 through the groove A83; the two ends of the second rectangular plate 82 in the axial direction are also provided with a groove B84, and the opening section of the groove B84 faces the bottom of the second rectangular plate 82 , the width of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com