Power transmission joint defense inspection system

A connecting rod and left-walking technology, applied in the direction of electrical components, cable installation, overhead line/cable equipment, etc., can solve the problems of poor work reliability, falling down, etc. fall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

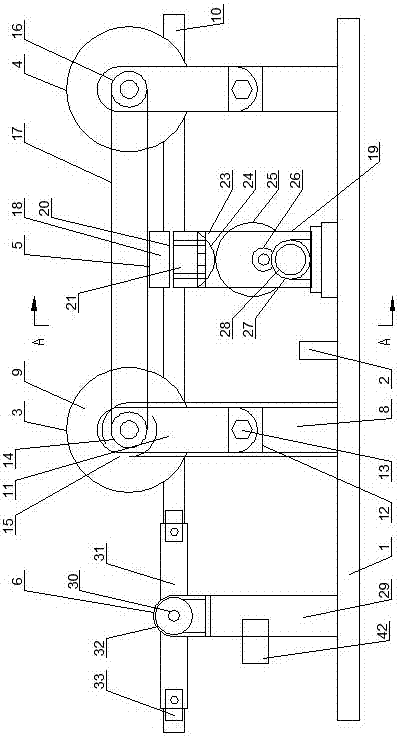

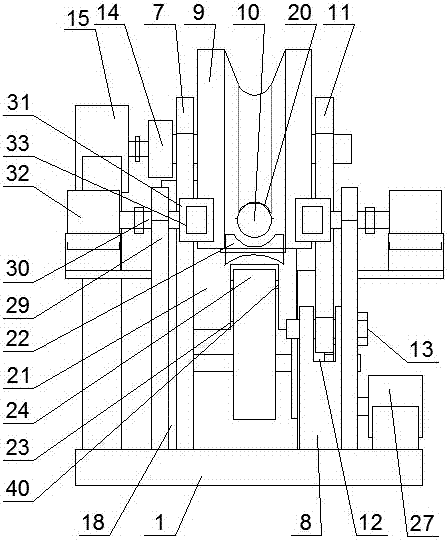

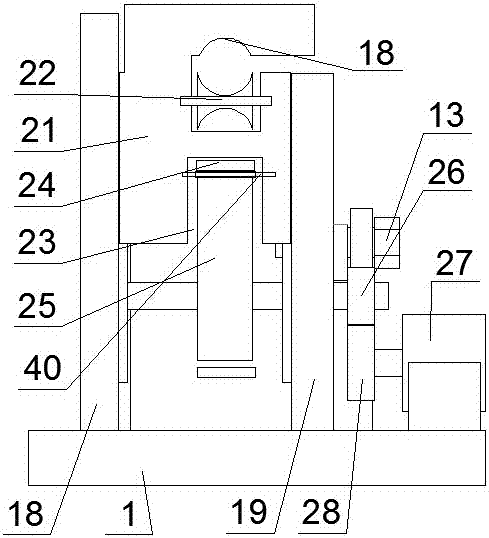

[0031] like figure 1 , figure 2 and image 3 As shown, a power transmission joint prevention and inspection system includes a base 1, a programmable controller 2 arranged on the base 1 and a camera 42 connected to the programmable controller, and a left walking mechanism with the same structure is set on the base 1 3 and the right traveling mechanism 4, a locking and deicing mechanism 5 is provided between the left traveling mechanism 3 and the right traveling mechanism 4, and a foreign matter handling mechanism 6 is arranged on the left side of the left traveling mechanism 3;

[0032]The left traveling mechanism 3 and the right traveling mechanism 4 all include a rear vertical board 7 and a front vertical board 8 oppositely arranged on the base 1, the height of the front vertical board 8 is lower than that of the rear vertical board 7, the upper end of the rear vertical plate 7 is provided with a walking wheel 9 through a rotating shaft, and the walking wheel 9 is pressed ...

Embodiment 2

[0045] The difference from Embodiment 1 is that anti-slip layers are provided in the upper arc-shaped groove 20 and the groove 22 of the wire wheel.

Embodiment 3

[0047] like figure 1 , figure 2 and image 3 As shown, a power transmission joint prevention and inspection system includes a base 1 . The programmable controller 2 and the camera connected with the programmable controller are arranged on the base 1, the left traveling mechanism 3 and the right traveling mechanism 4 with the same structure are arranged on the described base 1, and the left traveling mechanism 3 and the A locking and deicing mechanism 5 is arranged between the right traveling mechanism 4, and a foreign body processing mechanism 6 is arranged on the left side of the left traveling mechanism 3;

[0048] The left traveling mechanism 3 and the right traveling mechanism 4 all include a rear vertical board 7 and a front vertical board 8 oppositely arranged on the base 1, the height of the front vertical board 8 is lower than that of the rear vertical board 7, the upper end of the rear vertical plate 7 is provided with a walking wheel 9 through a rotating shaft, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com