Platform moving type wide industrial scanning equipment and scanning method

A scanning device and mobile technology, applied in the field of wide-format scanning, can solve the problems of no scan preview function, no flattening, no automatic focus, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

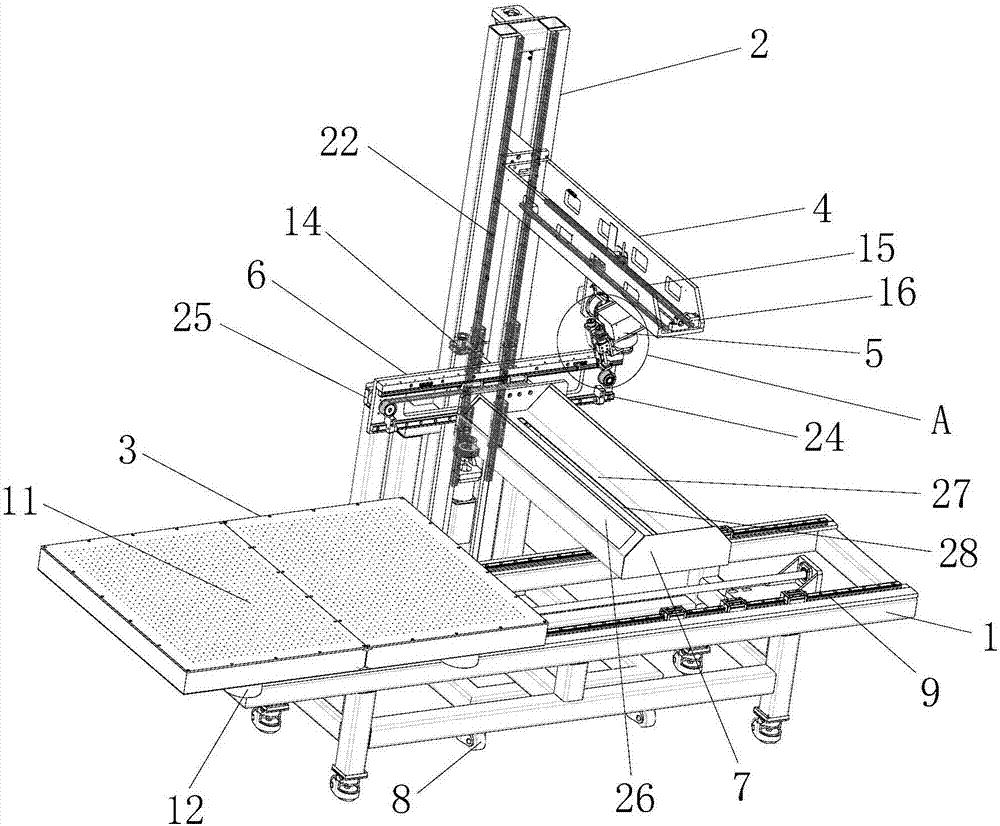

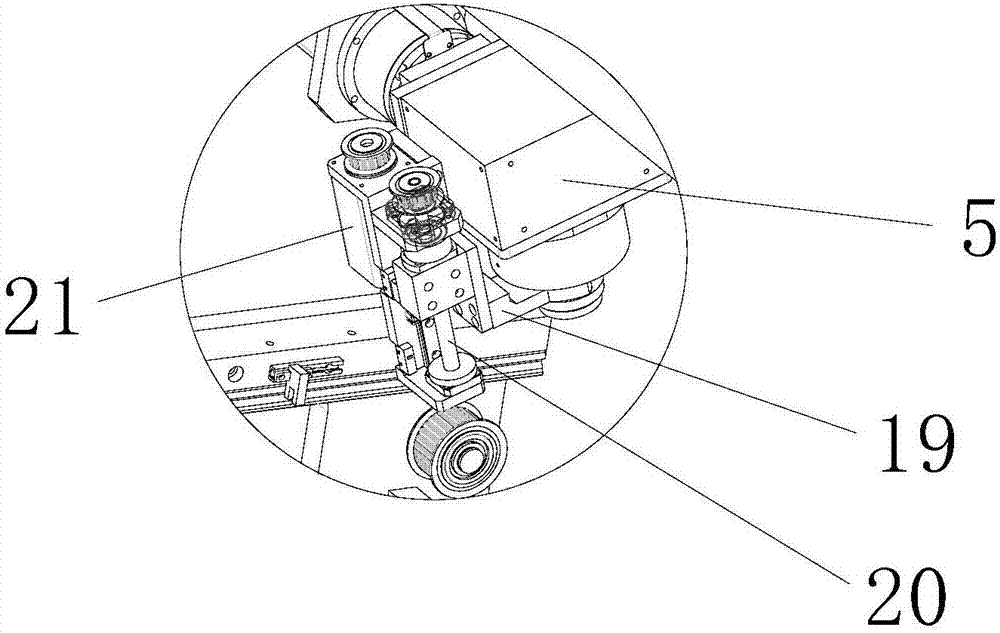

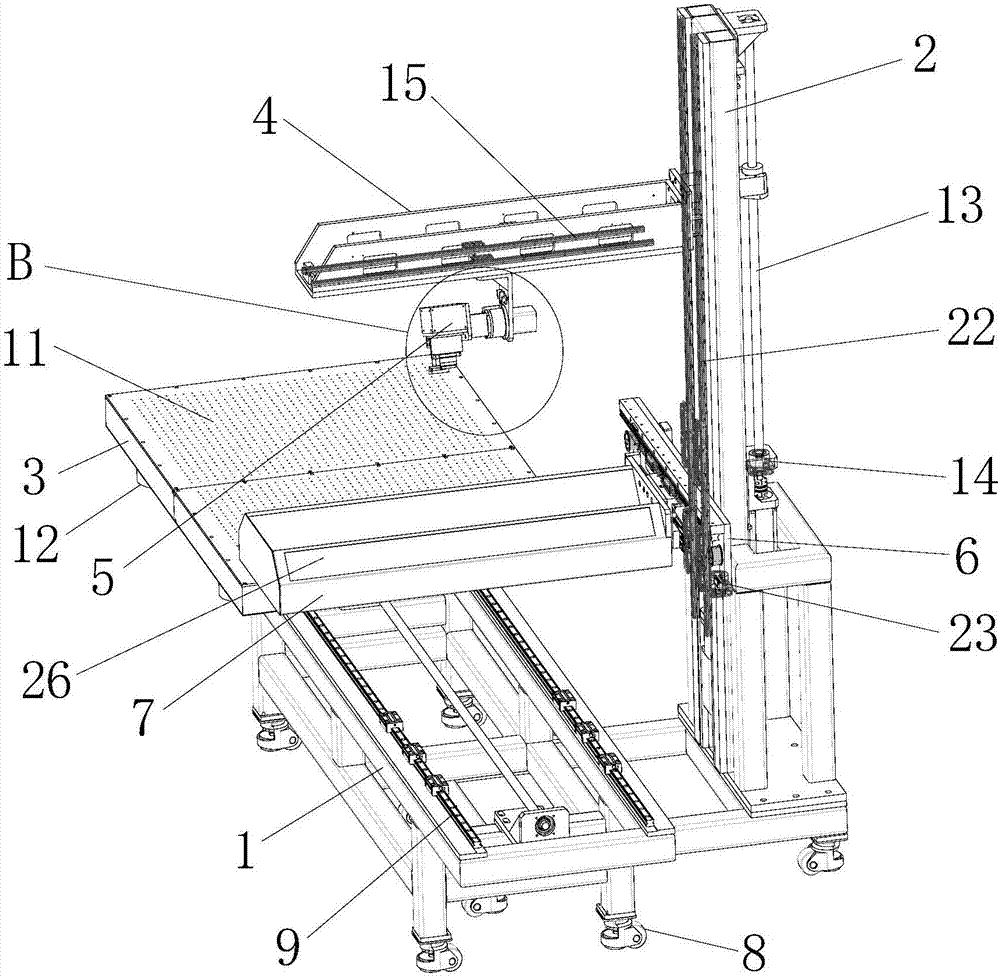

[0057] Such as Figure 1 to Figure 9 As shown, this embodiment provides a platform mobile wide-format industrial scanning device, the industrial scanning device includes a frame 1, a column 2, a platform 3, a cantilever 4, a line scan camera 5, a light stand 6, and a light support arm 7 and control device (not shown in the figure).

[0058] The bottom of the frame 1 is provided with universal casters 8, which is convenient for the user to move the whole equipment. and its control module) and a plurality of motor drivers are connected to the computer through the data line, and the scanning device can work normally after the power is turned on.

[0059] The platform 3 is connected with the frame 1 through the first slide rail 9, and is driven by the first motor 10 to move linearly (to the left or right) along the horizontal direction of the frame 1. The first motor 10 and the control device Connect; platform 3 is spliced by left platform and right platform, and the interior ...

Embodiment 2

[0075] Such as Figure 10 As shown, the main features of this embodiment are: the scanning device also includes an area array camera 30, the area array camera 30 is arranged on the top of the column 2, and is connected to the control device, the lens of the area array camera 30 faces the platform 3, And the field of view of the lens of the area array camera 30 covers the entire platform 3, and the range shown by the dotted line in the figure is the field of view of the lens; The figure does not require high resolution, and the size and shape of objects on the platform can be more accurately identified as a standard, and the megapixel level can meet the requirements. The position and angle between platforms 3 are fixed, and the area array camera 30 is controlled by the control software of the computer. When a preview is needed, select the preview button in the control software, and the area array camera 30 takes a picture on the platform 3 and outputs it to Control software, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com