Waterproof sheet and method for waterproofing construction

A technology of waterproof sheet and construction method, applied in the direction of gasket, infrastructure engineering, pressure-sensitive film/sheet, etc., can solve the problems of reduced adhesion, loss of pressure-sensitive adhesive layer, etc., and achieve excellent adhesion durability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

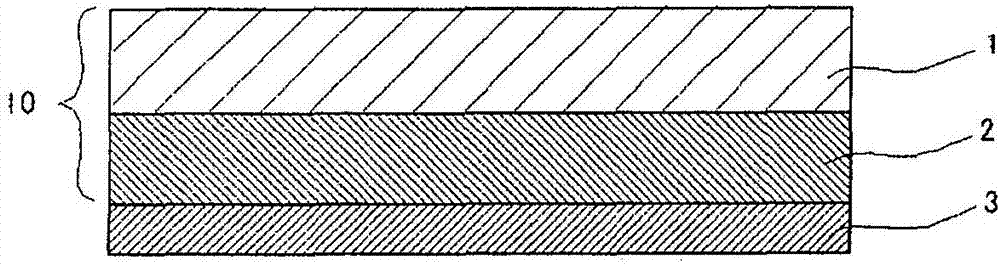

[0112] As an addition reaction curing type silicone rubber composition, in the kneading type dimethyl silicone rubber composition KE-675-U (manufactured by Shin-Etsu Chemical Co., Ltd.), C- 19A / 0.5 parts, C-19B / 2.4 parts (all manufactured by Shin-Etsu Chemical Co., Ltd.) were added and mixed, and formed into a sheet with a thickness of 0.7 mm on a 100 μm PET film with wrinkles by calendering, and continuously It heat-cured at 140 degreeC for 10 minutes in the heating furnace, and obtained the base material layer A in the state laminated|stacked on the PET film.

[0113] On the other hand, a compound composed of (CH 2 =CH)(CH 3 ) 2 SiO 1 / 2 unit, (CH 3 ) 3 SiO 1 / 2 Cell and SiO 2 A resinous copolymer composed of units [((CH 2 =CH)(CH 3 ) 2 SiO 1 / 2 Unit+(CH3 ) 3 SiO 1 / 2 unit) / SiO 2 Unit (molar ratio) = 0.85, CH 2 = CH-group content: 0.0008 mol / g] 7.5 parts of 50% toluene solution were put into a stirring mixer, and after mixing for 30 minutes, the toluene was comple...

Embodiment 2

[0117] A base material layer A was obtained in the same manner as in Example 1. In addition to being used as a cross-linking agent, the (CH 3 ) 2 HSio 1 / 2 Cell and SiO 2 The silicone rubber composition B, the adhesive composition B, and the 2 Layer の lamination cured sheet B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com