Easy adhesive for solar cell protection sheet, solar cell protection sheet, and solar cell module

A technology for solar cells and protective sheets, applied in the direction of film/sheet adhesives, non-polymer organic compound adhesives, adhesives, etc., can solve the problem of high cost, achieve small output reduction and adhesion durability The effect of excellent, excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0340] Using the sample 1 for adhesive force evaluation, the adhesiveness of the easy-adhesive layer to the EVA film and the adhesiveness of the heat-and-moisture test (after 1000 hours and after 2000 hours) were evaluated by the method described later.

[0341] Adhesion Evaluation

[0342] Cut the surface of the solar cell protection sheet 1 of the sample 1 for adhesion evaluation into a width of 15 mm with a cutter knife, and the gap between the easy-adhesive layer formed on the solar cell protection sheet 1 and the EVA film as a sealing material was cut. Adhesion was measured. A tensile tester was used for the measurement, and a 180-degree peel test was performed at a loading speed of 100 mm / min. The obtained measured values were evaluated as follows.

[0343] ◎: 50N / 15mm or more

[0344] ○: More than 30N / 15mm to less than 50N / 15mm

[0345] △: More than 10N / 15mm to less than 30N / 15mm

[0346] ×: less than 10N / 15mm

[0347] Adhesion evaluation after damp heat test

...

Embodiment 2~221、 comparative example 1~30

[0350] In the same manner as in Example 1, using samples 2 to 221 and 1' to 30' for adhesive force evaluation, the adhesiveness of the easily adhesive layer to the EVA film and the adhesiveness after the heat-and-moisture resistance test were evaluated. The above results are shown in Tables 13-1, 13-2, 13-3, 13-4, 14, 15-1A, 15-1B, 15-2, 15-3A, 15-3B, 16, 17-1A , 17-1B, 17-2A, 17-2B, 17-3A, 17-3B, 18, 19-1A, 19-1B, 19-2A, 19-2B, 19-3A, 19-3B, 20, 21 -1A, 21-1B, 21-2A, 21-2B, 21-3A, 21-3B, 22, 23-1, 23-2, 23-3, 24.

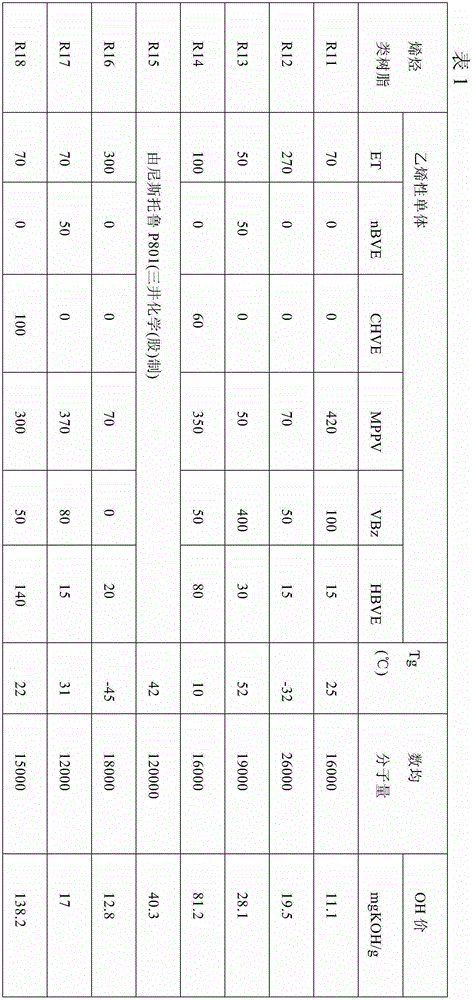

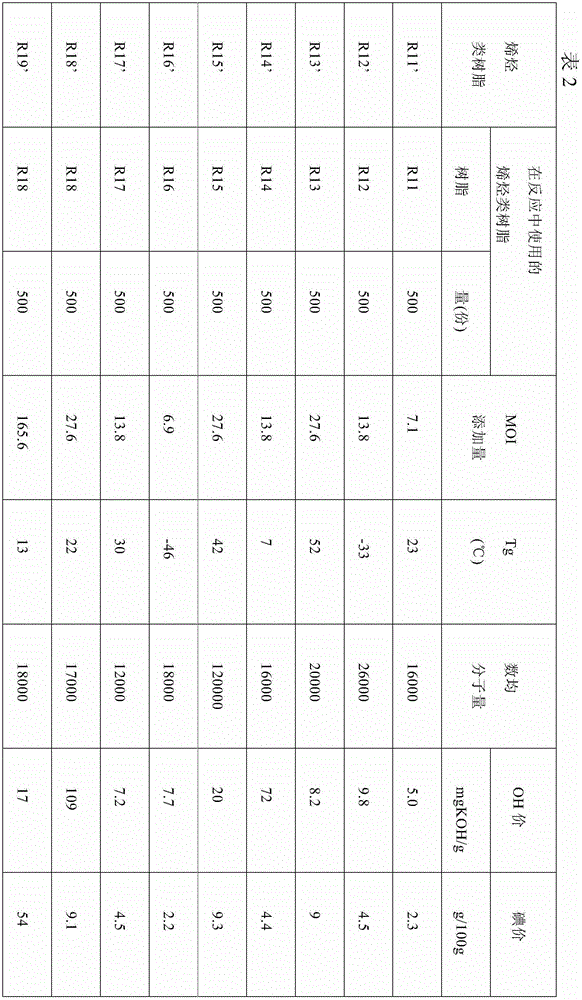

[0351] The abbreviations in Tables 13-1 to 24 indicate the contents shown below.

[0352] Compounds B1-B6 having a (meth)acryloyl group

[0353] Among the compounds B1 to B6 having a (meth)acryloyl group, the compounds described below were used as they were.

[0354] B1: Aronicus M-215 (manufactured by Toagosei Co., Ltd., isocyanuric acid EO-modified diacrylate)

[0355] B2: Aronicus M-315 (manufactured by Toagosei Co., Ltd., isocyanuric acid EO-modified triacr...

Embodiment 222

[0418] Manufacture of solar cell modules

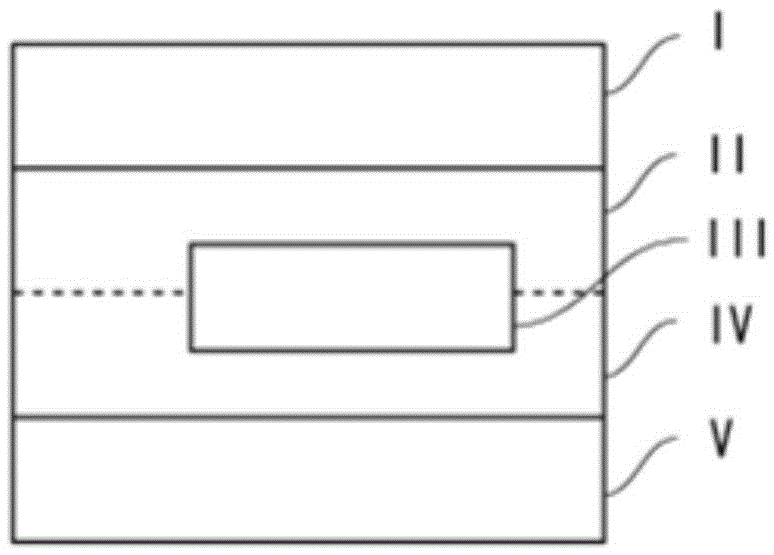

[0419] Whiteboard glass・・・Solar cell surface protection material (I)

[0420] EVA film...Sealing material on the light receiving side (II)

[0421] Polycrystalline silicon solar cell element···solar cell (III)

[0422] EVA film...Sealing material on the non-light-receiving side (IV)

[0423] The above-mentioned (I)-(IV) and the solar cell protection sheet 1 are stacked in order so that the easy-adhesive layer of the solar cell protection sheet 1 is in contact with the sealing material (IV) on the non-light-receiving side side, and then put into a vacuum laminator , evacuated to about 1 Torr, under the state of applying atmospheric pressure as pressurized pressure, heated at 150°C for 30 minutes, and then heated at 150°C for 30 minutes to make a 10cm×10cm square photoelectric conversion efficiency evaluation. battery module 1.

[0424] Determination of Photoelectric Conversion Efficiency

[0425] The solar cell output of the obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com