Preparation method of glutinous rice flour with milling by semi-dry process

A glutinous rice flour, semi-dry technology, applied in grain processing, food science and other directions, can solve the problems of easy clogging of sieves, reduce the whiteness of glutinous rice flour, yellowing of glutinous rice flour products, etc., to reduce browning reaction and maintain color. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Treatment of glutinous rice grains with superheated steam

[0038] The water content of the glutinous rice raw material after milling is about 15%. It is transported from the raw material tank to the superheated steam equipment for processing, and it is set at 150°C for 30 seconds. At this time, the moisture in the glutinous rice is reduced to about 13%.

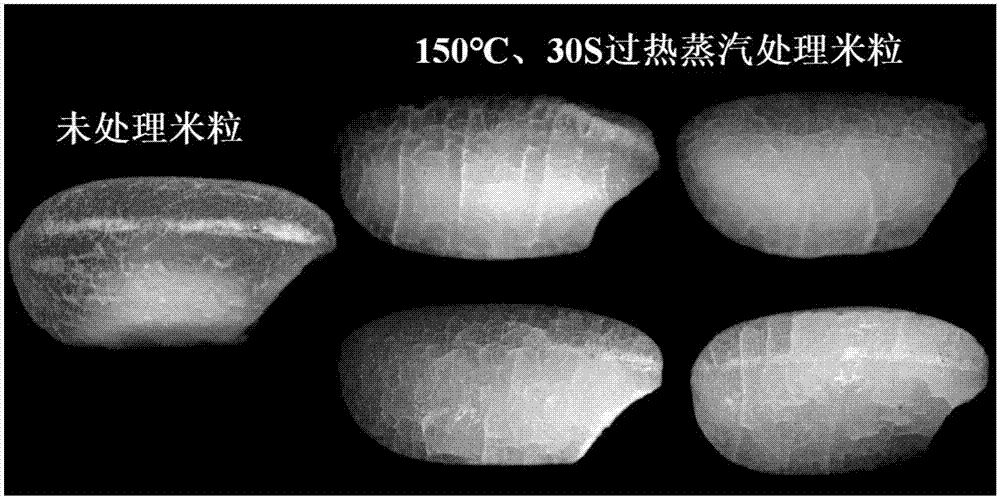

[0039] After the superheated steam treatment in this step, a large number of cracks and transverse cracks deep into the interior of the rice grains are produced on the surface of the rice grains, such as figure 1 The shown stereomicrograph of rice grains (observed and taken by SMZ800N stereomicroscope) is conducive to subsequent water absorption.

[0040] (2) Adding water to reduce the hardness of rice grains

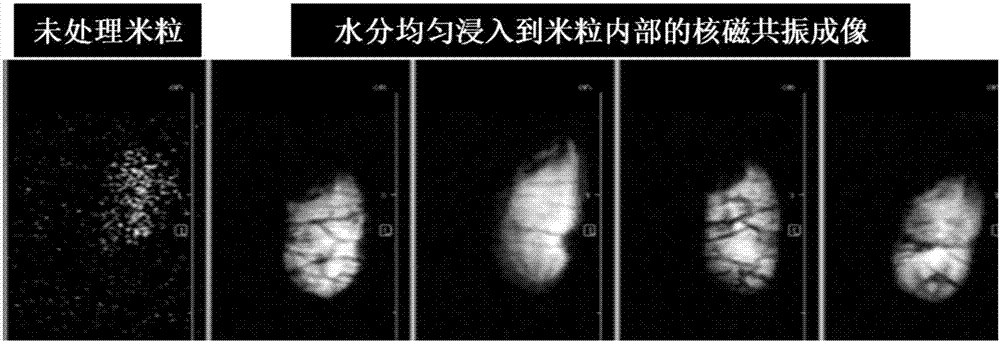

[0041] The rice grains are quantitatively watered by spraying, and water is added according to the saturated water absorption rate of different glutinous rice varieties, so that the moisture content of the...

Embodiment 2

[0054] (1) Treatment of glutinous rice grains with superheated steam

[0055] The water content of the glutinous rice raw material after grinding is about 15%, and it is transported from the raw material tank to the superheated steam equipment for processing, and the treatment is set at 180°C for 90 seconds, and the moisture in the glutinous rice is reduced to about 12%. A large number of cracks are produced on the surface of the rice grains, and at the same time, the rice grains produce transverse cracks that penetrate deep into the interior of the rice grains (the photomicrograph of the rice grains and the figure 1 There is no substantial difference), which is conducive to subsequent water absorption.

[0056] (2) Adding water to reduce the hardness of rice grains

[0057] The rice grains are quantitatively watered by spraying, and water is added according to the saturated water absorption rate of different glutinous rice varieties, so that the moisture content of the gluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com