A method for inhibiting browning of chitosan oligosaccharides

A technology of chitosan oligosaccharide and browning, which is applied in the fields of enzyme engineering and fermentation engineering, can solve problems such as limiting the popularization and application of chitosan oligosaccharide, reducing biological activity, and affecting product quality, so as to reduce amino browning reaction, convenient operation, and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

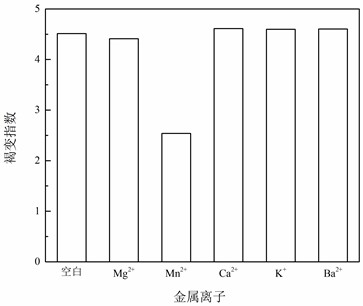

[0028] Example 1 Influence of metal ions on browning of chitosan hydrolyzed solution To 600 mL of chitosan acetic acid solution with a concentration of 0.10 g / mL, 6 mL of chitosanase-containing solution (the amount of enzyme added is 2.5 U / mL) was added. g chitosan). Divide into 6 parts, take 5 parts of them, add MgCl respectively 2 , MnCl 2 , CaCl 2 , KCl, BaCl 2 , the final concentration of metal ions was 1 mmol / L, and the last part without metal ions was used as a control to react at 55 °C, 200 rpm water bath shaker for 6 hours; the enzymatic hydrolysis solution was diluted with water, and the volume of the enzymatic hydrolysis solution and water was The ratio was 1:9, the absorbance was measured at 420 nm, and the measured value was used as the browning index to explore the effect of metal ions on the browning of chitosan oligosaccharides.

[0029] The result is as figure 1 As shown, when there is 1 mmol / L Mn in the enzymatic hydrolysate, compared with no metal ions a...

Embodiment 2

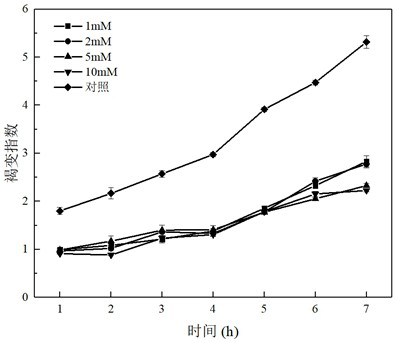

[0030] Example 2 Browning control of chitosan hydrolyzed solution To 500 mL of chitosan acetic acid solution with a concentration of 0.10 g / mL, 5 mL of chitosanase-containing solution (the amount of added enzyme was 2.5 U / g of chitosan) was added. ). Divide into 5 parts, take 4 parts of them, add MnCl respectively 2, so that the final concentrations were 1 mmol / L, 2 mmol / L, 5 mmol / L, 10 mmol / L, respectively, and the last part did not add MnCl 2 , as a control, the reaction was carried out at 55°C and 200 rpm in a water bath shaker, and samples were taken at intervals of 1 hour from the start of the reaction. Dilute the enzymatic hydrolysis solution in different time periods (1 hour, 2 hours, 3 hours, 4 hours, 5 hours, 6 hours, 7 hours) with water. The absorbance value was measured at lower temperature, and the measured value was used as the browning index to explore the optimal Mn to inhibit the browning of chitosan oligosaccharide. 2+ concentration.

[0031] The experimen...

Embodiment 3

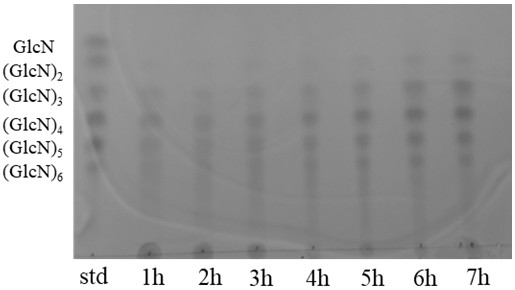

[0033] Example 3 Changes in the final product of enzymatic hydrolysis To 200 mL of 0.10 g / mL chitosan acetic acid solution, 2 mL of chitosanase-containing solution (the amount of enzyme added is 2.5 U / g of chitosan) is added. Divide into 2 parts, one of which is added with MnCl 2 , so that the final concentration is 5 mmol / L (as the experimental group), and the other part does not add Mn 2+ (as a control group), the reaction was carried out at 55° C., 200 rpm in a water bath shaker, and samples were taken at intervals of 1 hour from the start of the reaction.

[0034] Thin-layer chromatography (TLC) was used to analyze the product of the hydrolysis of chitosan by the enzyme solution, and the obtained sample was spotted and then developed twice in a developing solvent (isopropanol-water-ammonia with a volume ratio of 8:3:1). , after the development is finished, blow dry with a hair dryer and dye with a dye (0.1% ninhydrin-ethanol solution), develop the color at 110 °C for 10 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com