Method for dipping and modifying activated carbon, and application

A technology of activated carbon and modification, applied in the fields of application, chemical instruments and methods, food science, etc., can solve problems such as adverse effects of flue-cured cigarette smoking, so as to relieve dryness and irritation, enhance aroma, and improve smoking taste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Take 50g of activated carbon (French Pickup Company, BCCplus model coconut shell activated carbon, add 0.1mol / L different acid aqueous solution 150mL respectively, impregnate and modify for 24h, and dry at 120°C for 24h to prepare modified activated carbon.

[0033] The specific surface area of the modified activated carbon was tested, and the test results are shown in Table 1. The specific surface area of the activated carbon treated with 0.1mol / L of different acid aqueous solutions was changed compared with that of the activated carbon not impregnated with the acid, but the change was not significant.

[0034] The specific surface area of activated carbon after table 1 is treated with 0.1mol / L different acid aqueous solution

[0035]

Embodiment 2

[0037] Taking citric acid as an example, describe the implementation process.

[0038] Take 50g of activated carbon (French Pickup Company, BCCplus model activated carbon) and add 150mL of aqueous solutions of citric acid with different mass concentrations, impregnate and modify for 24h, and dry at 120°C for 24h to prepare modified activated carbon.

[0039] The specific surface and pore structure of the modified activated carbon were tested, and the test results are shown in Table 2. The specific surface area and total pore volume of the modified activated carbon changed significantly with the change of the mass concentration of citric acid.

[0040] Table 2 Pore structure parameters of activated carbon modified with different mass concentrations of citric acid

[0041]

[0042]

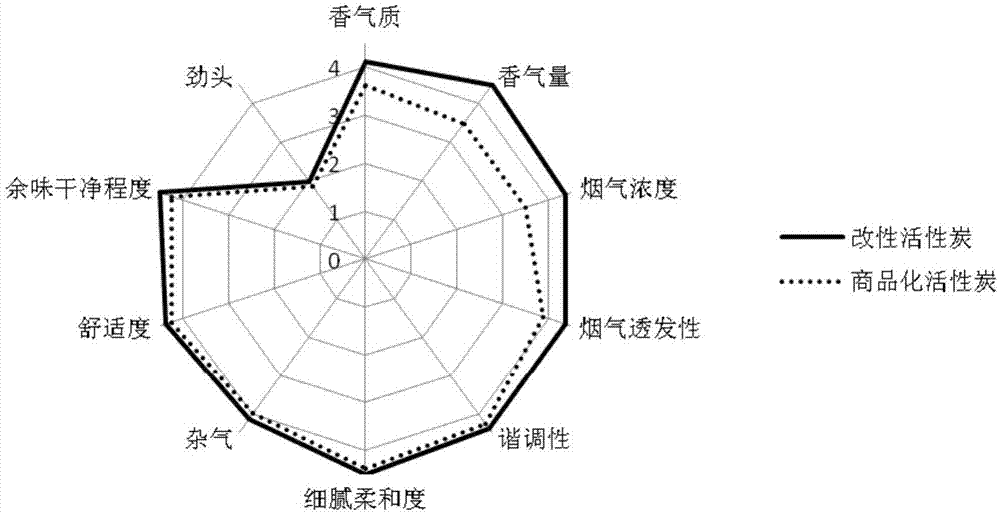

[0043] Cigarette smoking shows that the activated carbon impregnated with 5% mass concentration of citric acid has the best effect.

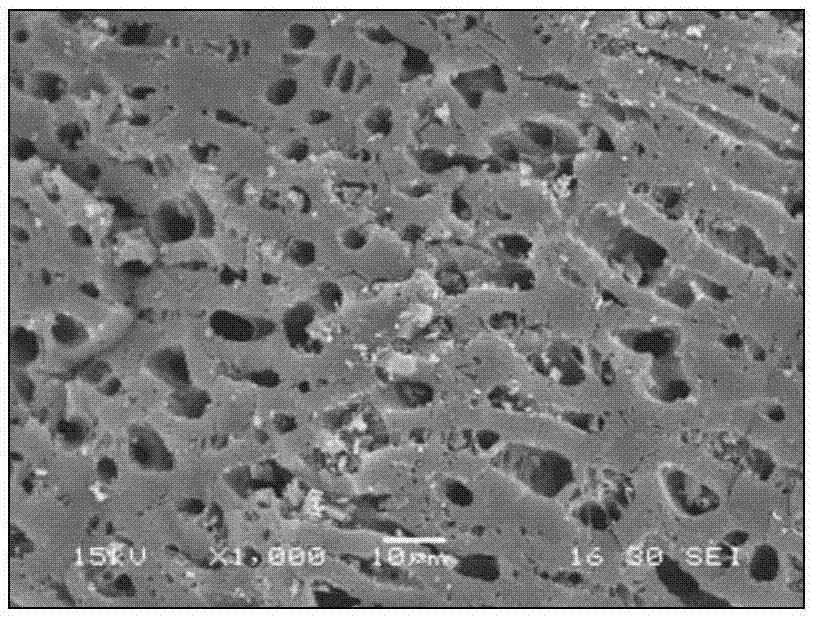

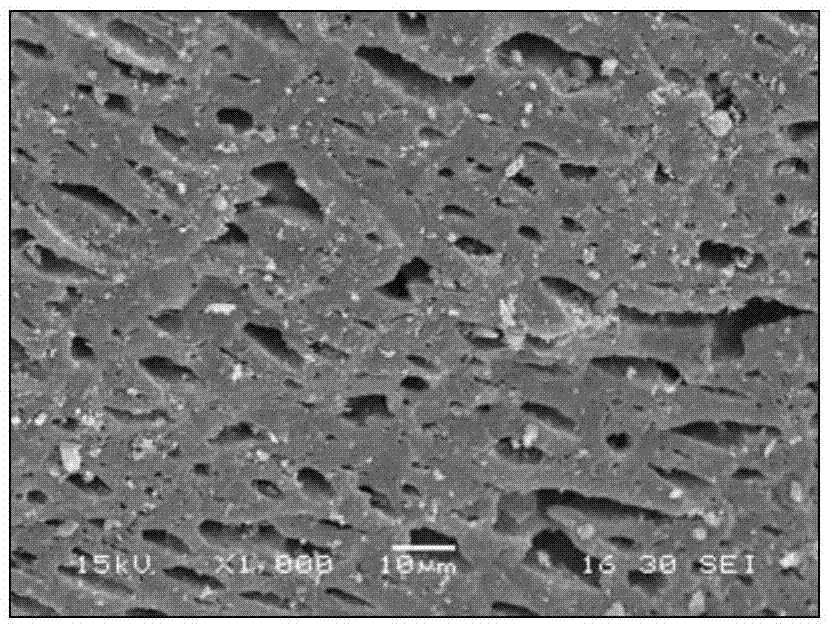

[0044] like figure 1 and figure 2 (mass concentration ...

Embodiment 3

[0048] In order to investigate the actual harm-reducing effect of modified activated carbon, the modified activated carbon impregnated with 10wt% citric acid aqueous solution prepared in Example 2 was applied to filter-tip cigarettes, and the analysis of 7 harmful components in cigarette smoke and the overall harm The results are shown in Table 3. It can be seen that although the specific surface area of modified activated carbon is smaller than that of unmodified activated carbon, it can still achieve better reduction after modification by impregnation. Harmful effect; when applied to the same brand of cigarettes, compared with unmodified activated carbon, modified activated carbon, NH 3 , NNK, BaP, and phenol content all decreased, and at the same time, the overall hazard index decreased.

[0049] Analysis methods of seven harmful components: CO analysis is in accordance with GB / T 23356-2009 standard; HCN analysis is in accordance with YC / T253-2008 standard; NNK analysis i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com