Method for transforming milling cutter into grooving cutter and UC grooving cutter

A technology for slotting cutters and milling cutters, which is applied in the field of methods and UC slotting cutters, and milling cutters for changing slotting cutters. It can solve the problems of discarding old milling cutters, difficult processing of slotting cutters, and cumbersome steps, and achieves easy processing and reduced processing difficulty. Small, easy-to-step effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

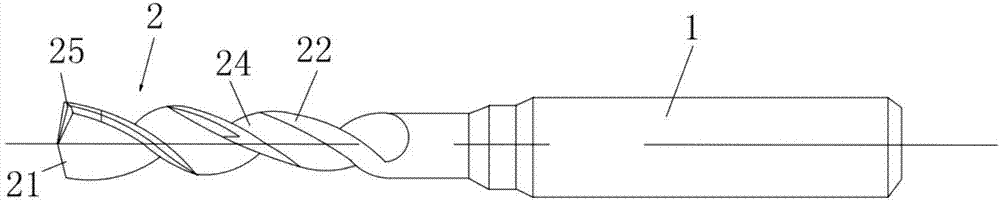

[0037] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

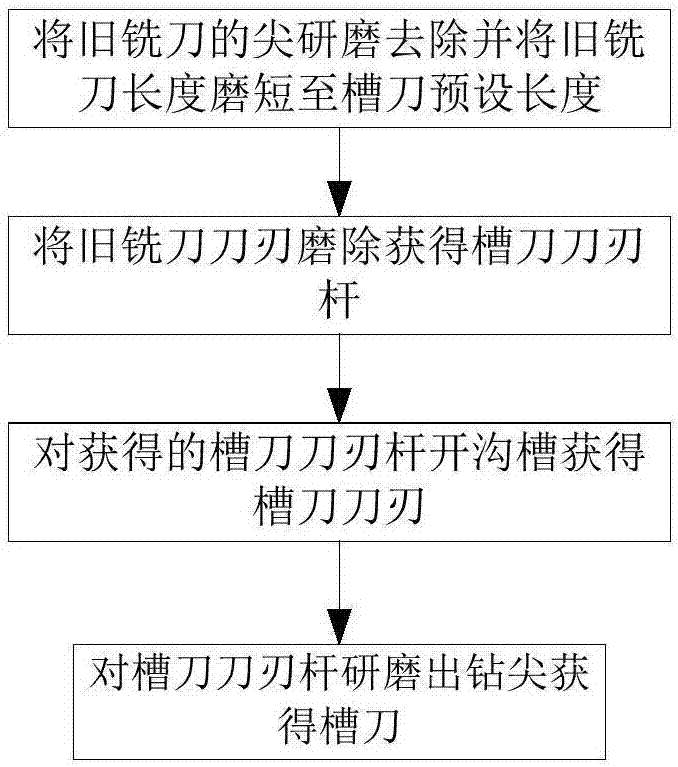

[0038] Such as figure 1 As shown, the present embodiment provides a method for changing a milling cutter to a slotting cutter. The method can change an old milling cutter into a slotting cutter through grinding, grooving and other processes, and specifically includes the following steps;

[0039] Step 1. Grinding and removing the tip of the old milling cutter and shortening the length of the old milling cutter to the preset length of the slotting cutter;

[0040] The preset length in this embodiment refers to the length specified by the user. It should be noted that the length of the old milling cutter needs to be larger than the preset length of the slot cutter. For example, if the old m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com