Curing method of phenolic composite material self-lubricating bearing

A technology of self-lubricating bearings and composite materials, which is applied to other household appliances, household appliances, household components, etc., can solve the problems of shortening the service life of bearings, shedding of the surface of the gasket, and accelerating the wear of the gasket, so as to improve performance and service life , Exclude air bubbles, improve the effect of compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

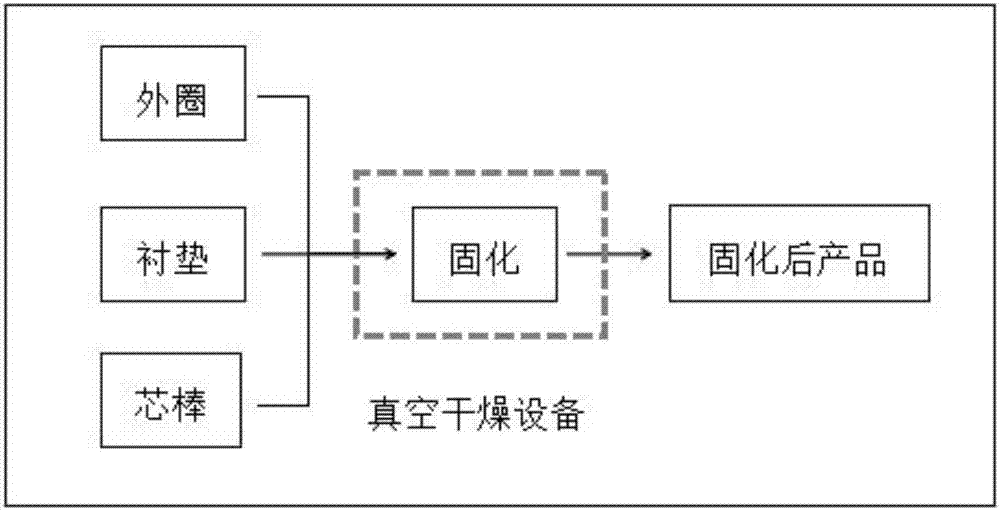

[0017] This embodiment relates to a curing method for a phenolic composite material self-lubricating bearing, such as figure 1 shown, including the following steps:

[0018] 1. Prepare trays, ovens, phenolic composite material liners, mandrels, and outer steel rings of bearings;

[0019] 2. Paste the gasket into the outer steel ring of the bearing with phenolic sealant, and cure at room temperature;

[0020] 3. Put the gasketed outer steel ring of the bearing on a mandrel of appropriate size, put it in a tray, transfer it to a vacuum drying oven, and use the method of temperature programming to increase the temperature from room temperature at a rate of 6-8°C / min. , slowly rise to 160-180°C, keep for 2h, then drop to 130-150°C at a cooling rate of 1-2°C / min, keep for 1h, then cool to room temperature in a natural state to complete the curing treatment.

[0021] This embodiment adopts a vacuum drying and curing process. Through thermogravimetric analysis, compared with the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com