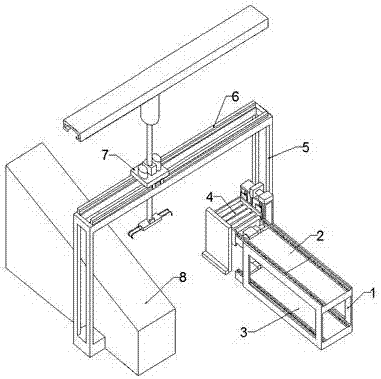

Automatic on-line system for automotive seat cushions

A technology of automatic on-line, car seat cushion, applied in the direction of conveyor objects, transportation and packaging, can solve the problems of high labor consumption, matching use of seat cushions, and high cost, and achieve the effect of reducing labor intensity, improving work efficiency, and eliminating potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

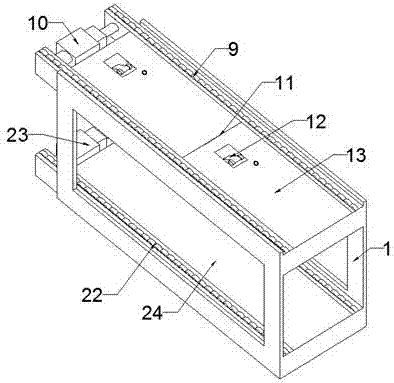

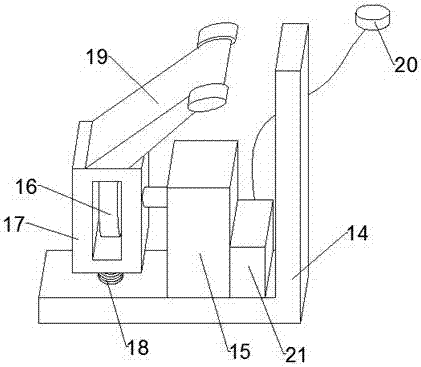

[0038]During the processing and transportation of the car seat cushion, the car seat cushion is placed on the tray, and then the tray with the car seat cushion is placed on the upper conveying device 2, driven by the conveying motor I10, and conveyed through the conveying chain I9, when the car is loaded When the tray of the seat cushion is conveyed to the position of the photoelectric sensor 20 of the tray stopper 12 at the rear of each laminate 13, the photoelectric sensor 20 senses that the tray carrying the car seat cushion moves over, and the photoelectric sensor 20 senses the load. When the tray with the car seat cushion moves, the photoelectric sensor 20 transmits the induction signal to the micro motor controller 21, and the micro motor controller 21 controls the micro motor 15 to start, and the micro motor 15 drives the cam 16 installed on its rotating shaft to rotate half a circle , so that the protruding part of the cam 16 is turned to the uppermost end and the jacki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com