Quartz rod bubble detection and quality grading method based on machine vision

A technology of machine vision and detection method, which is applied in the direction of instruments, analysis materials, image analysis, etc., can solve the problems of high cost of manual detection, high misjudgment rate, and restrictions on the development of quartz rod manufacturing industry, etc., and achieve strong anti-environmental light interference ability , the effect of unified testing standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

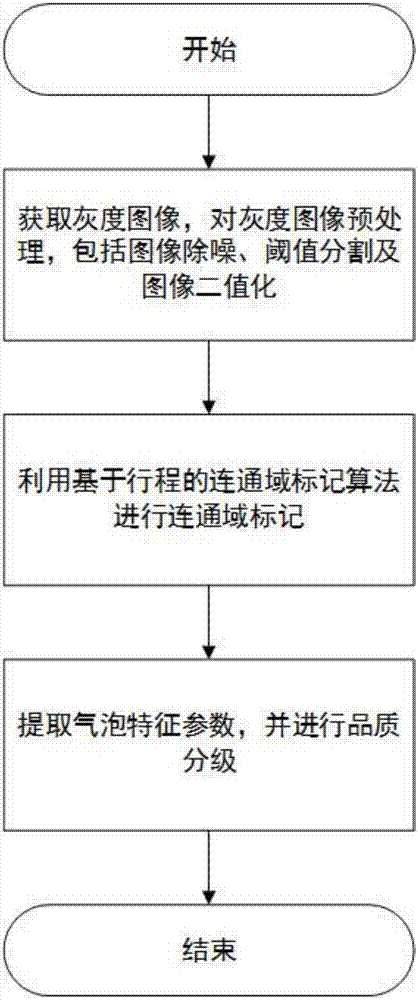

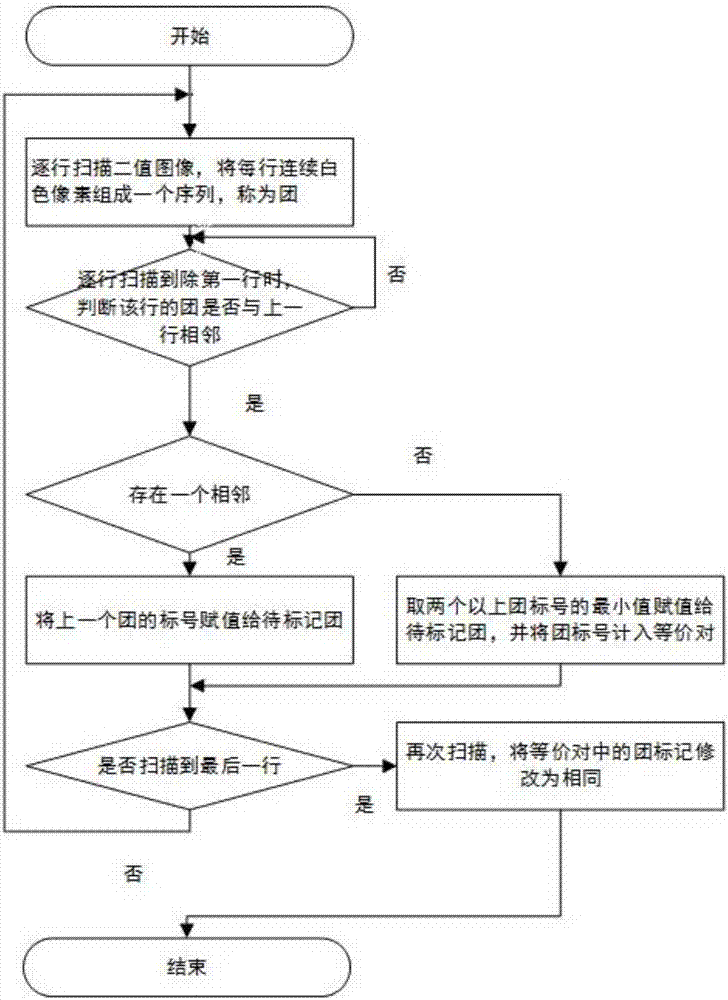

[0031] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

[0032] Step 1, collect the grayscale image of the cross-section of the quartz rod.

[0033] Soak the quartz rod in the medium liquid, the refractive index of the medium liquid is close to that of the quartz rod, and the viscosity is low. The quartz rod is placed in a dark room, the laser beam emitted by the laser light source illuminates the quartz rod from one side, and the industrial camera photographs the quartz rod to obtain a grayscale image of the cross-section of the quartz rod.

[0034] Step 2, denoising, thresholding, and binarizing the grayscale image in sequence to obtain a binary image.

[0035] In this step, the balanced threshold segmentation method is used for threshold segmentation, specifically:

[0036] For the grayscale image, the threshold is determined by the maximum inter-class variance threshold selection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com