Sensor used for magnetic conductivity measurement and measurement method thereof

A measurement method and sensor technology, applied in magnetic properties measurement, permeability measurement, etc., can solve the problems of large system error of self-inductance/mutual inductance, long processing and preparation cycle, and low accuracy of magnetic permeability measurement, so as to facilitate structural optimization , avoid the edge effect at both ends, and facilitate the effect of parameter correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The sensor and measurement method for magnetic permeability measurement of the present invention will be described with reference to the drawings and embodiments.

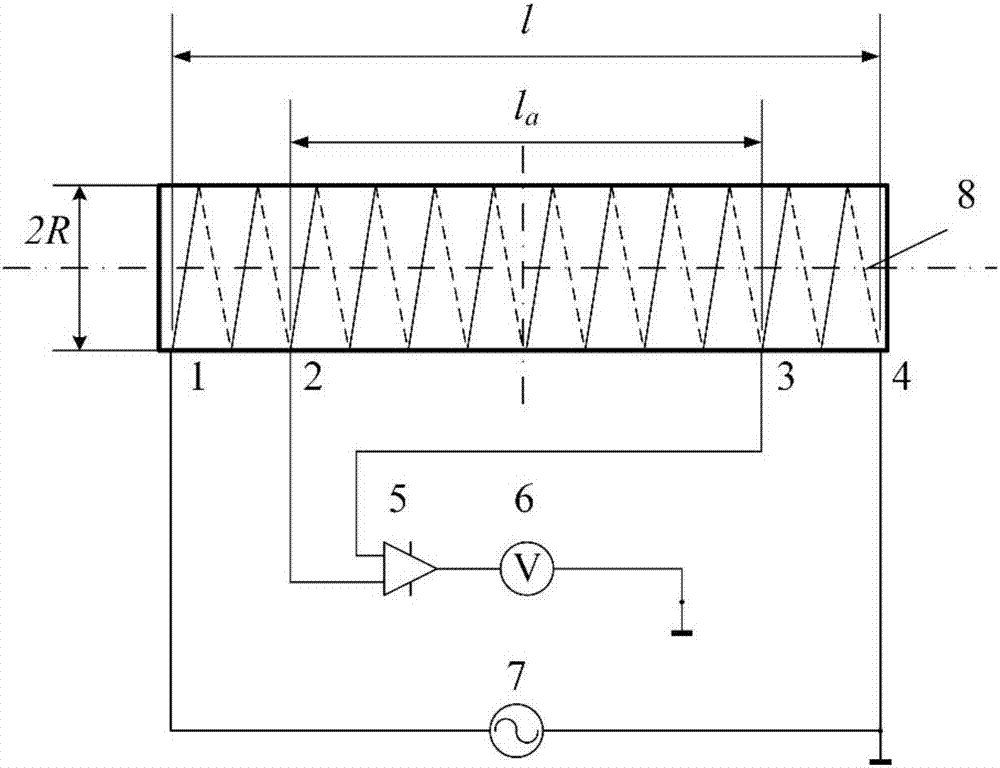

[0014] The structure of the sensor used for magnetic permeability measurement of the present invention is: the sensor includes a four-tap solenoid coil 8, and the solenoid coil 8 draws four taps sequentially from top to bottom, and the first tap in the four taps 1 is connected to the excitation current source 7, the fourth tap 4 is connected to the ground potential to form a current loop, the second tap 2 and the third tap 3 are connected to the input of the instrumentation amplifier 5 to obtain a differential voltage, and are connected to the voltage measurement module 6. The voltage measurement module 6 is one of an LCR meter, a digital multimeter or an instrument with an AC voltage measurement function.

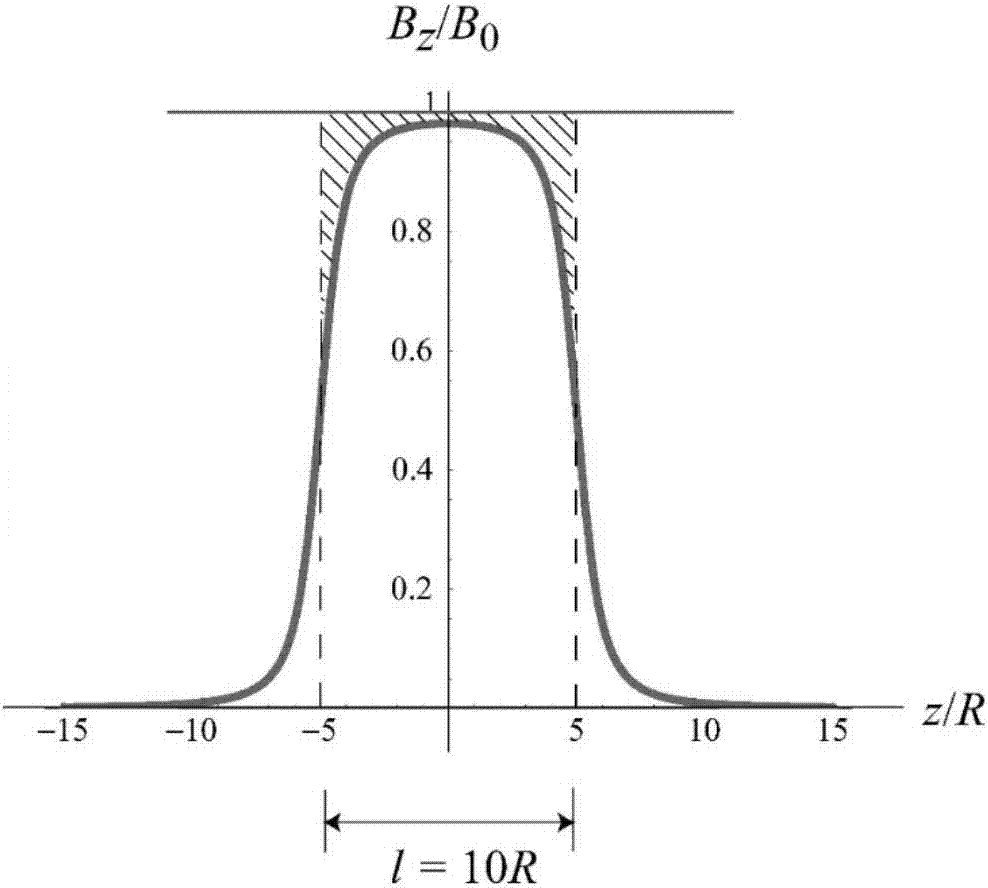

[0015] For the case where the solenoid coil 8 is infinitely long, its diameter is recorded as R, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com