Magnetic steel interleaved multistage axial magnetic flux permanent magnet kinetic energy apparatus

A staggered, magnetic steel technology, applied in electromechanical devices, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problem that the axial motor power cannot be increased, it does not have mass production, and the production process is complicated. and other problems, to achieve the effect of simple and reliable placement, convenient electrical connection, and reduced complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Explanation of terms:

[0033] Axial: Refers to the direction of the axis of rotation.

[0034] Magnetic steel: It means the same as permanent magnet.

[0035] Magnetization direction: refers to the direction of the magnetic circuit.

[0036] In the description of the following specific embodiments, in order to clearly demonstrate the structure and working mode of the present invention, many directional words will be used to describe, but "front", "rear", "left", "right", "outer Words such as ", "inwardly", "outwardly", "inwardly", "axially" and "radially" are to be understood as convenient terms and should not be understood as limiting terms. Wherein, the qualifier of "a" in "a group" in this article does not refer to a limitation on the quantity.

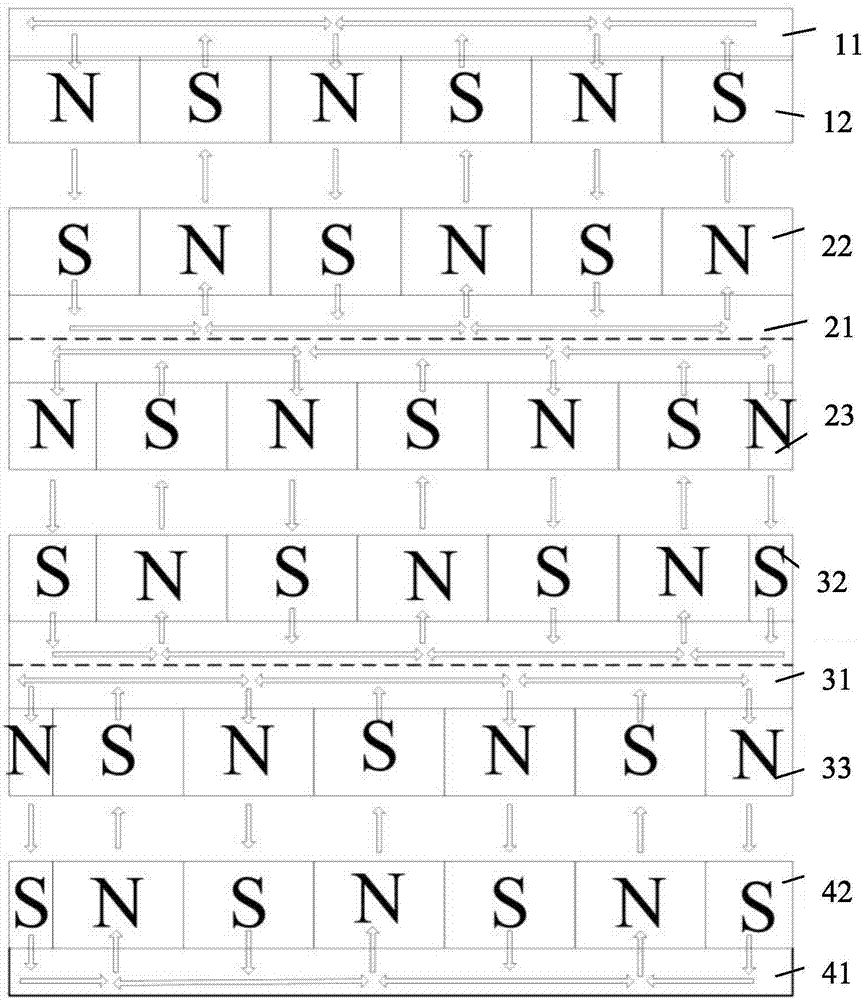

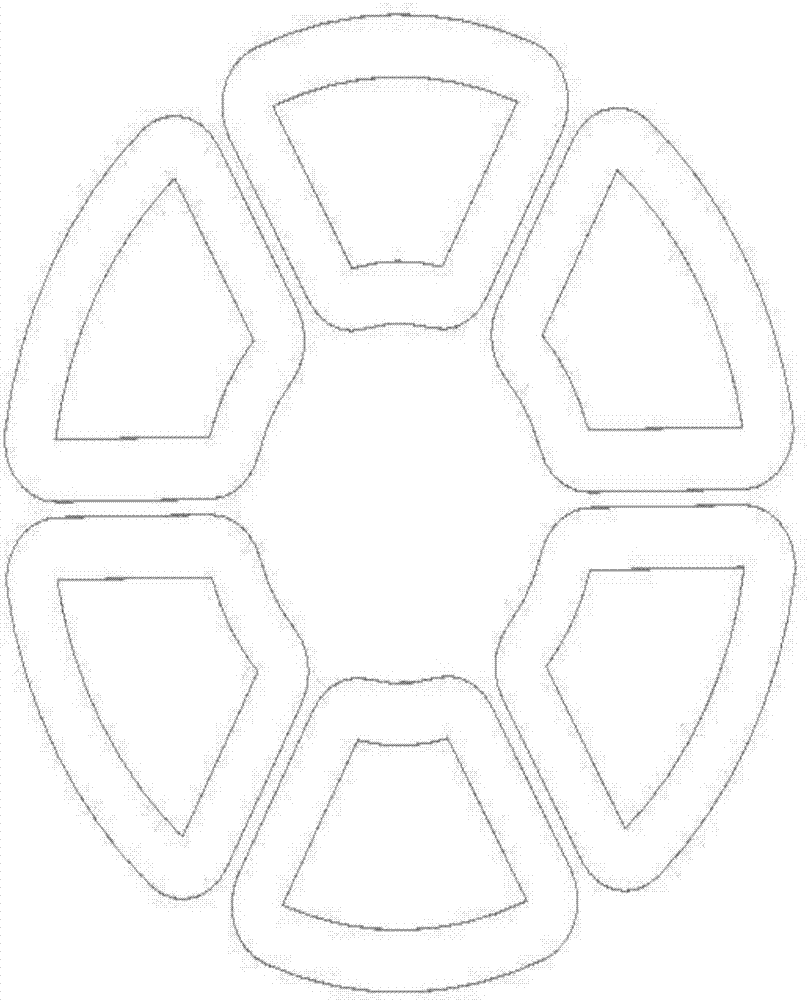

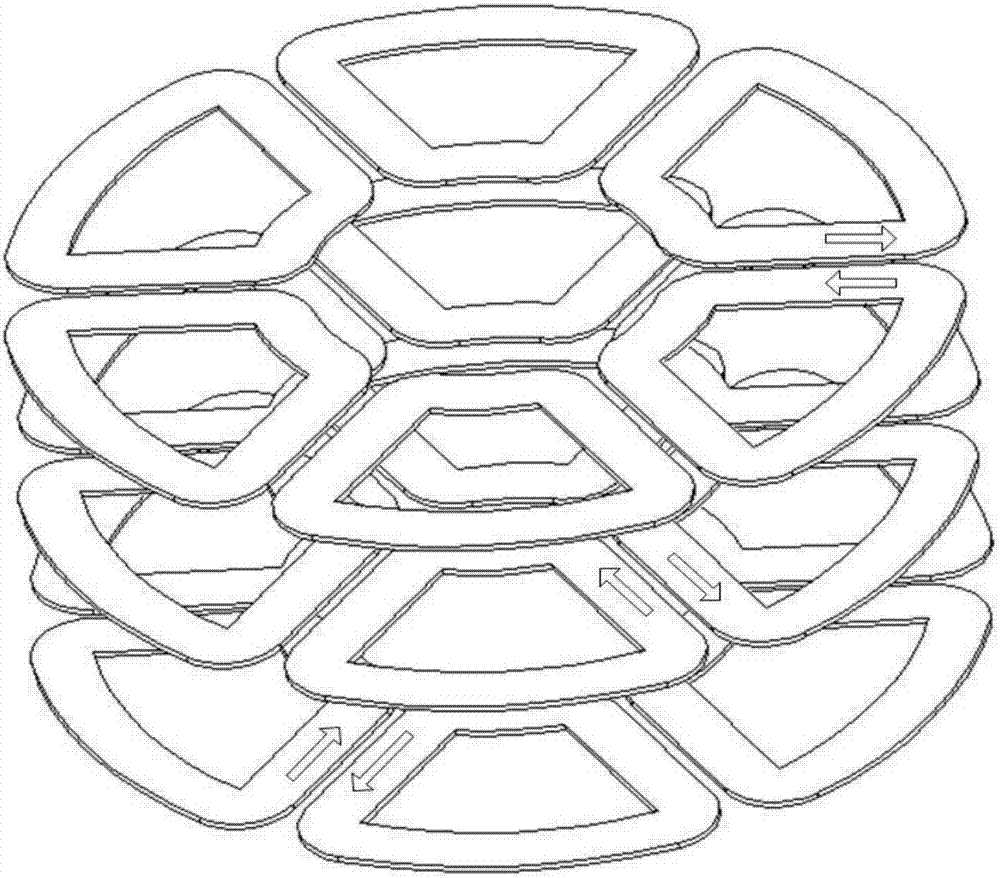

[0037] The rotor is glued with a number of permanent magnet disks arranged alternately in N and S polarities. The stator and rotor are respectively circular disk-shaped structures. The stator disk and rotor disk are plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com