Vibration and temperature difference composite piezoelectric self-generating battery

A composite, piezoelectric technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, battery circuit device, etc., can solve problems such as single

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

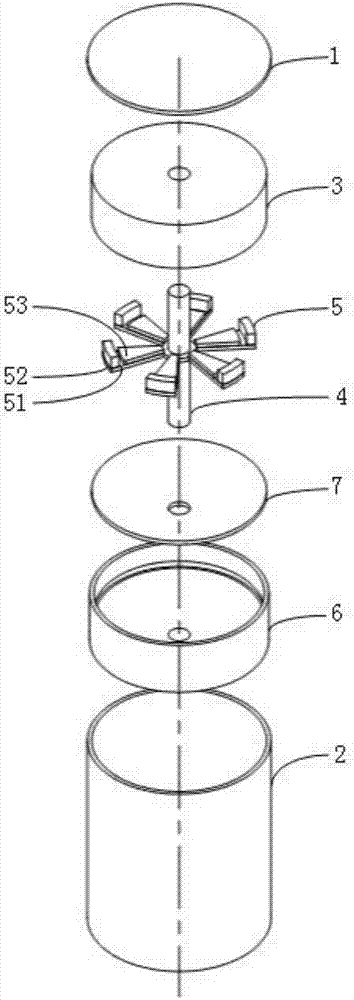

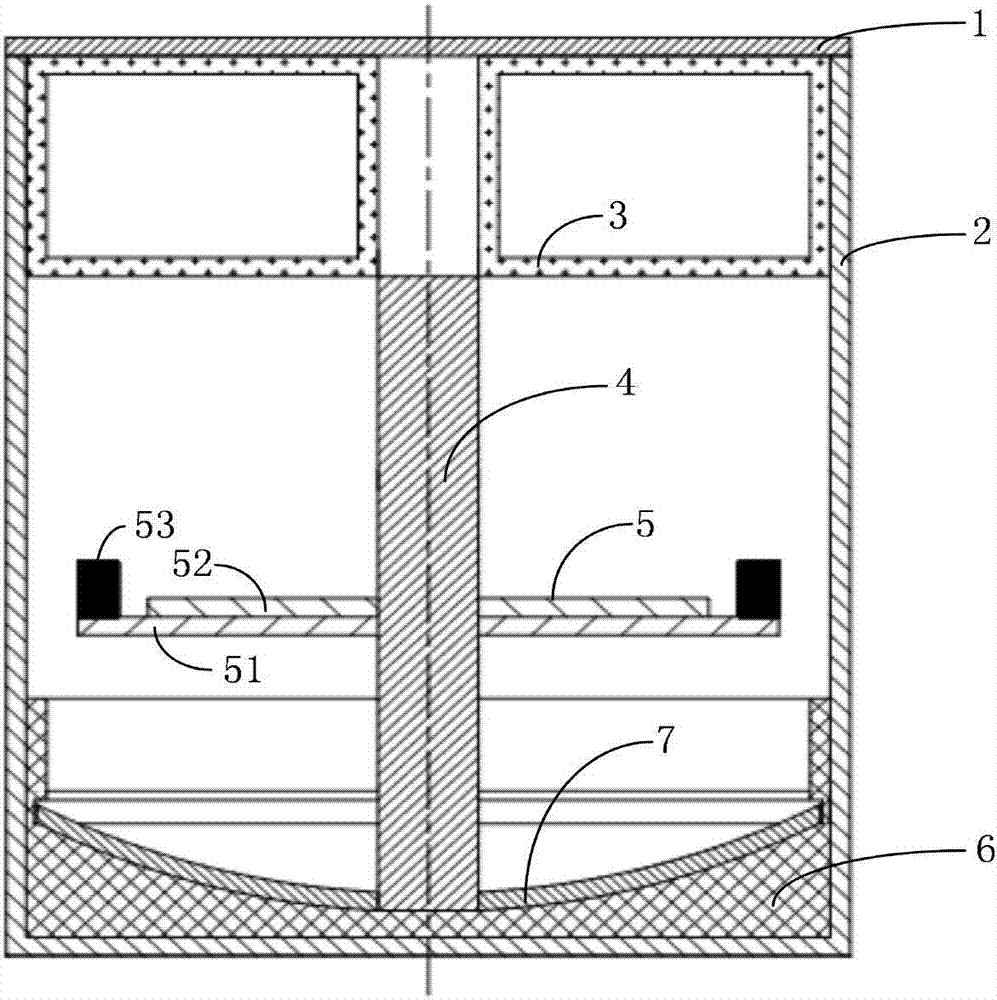

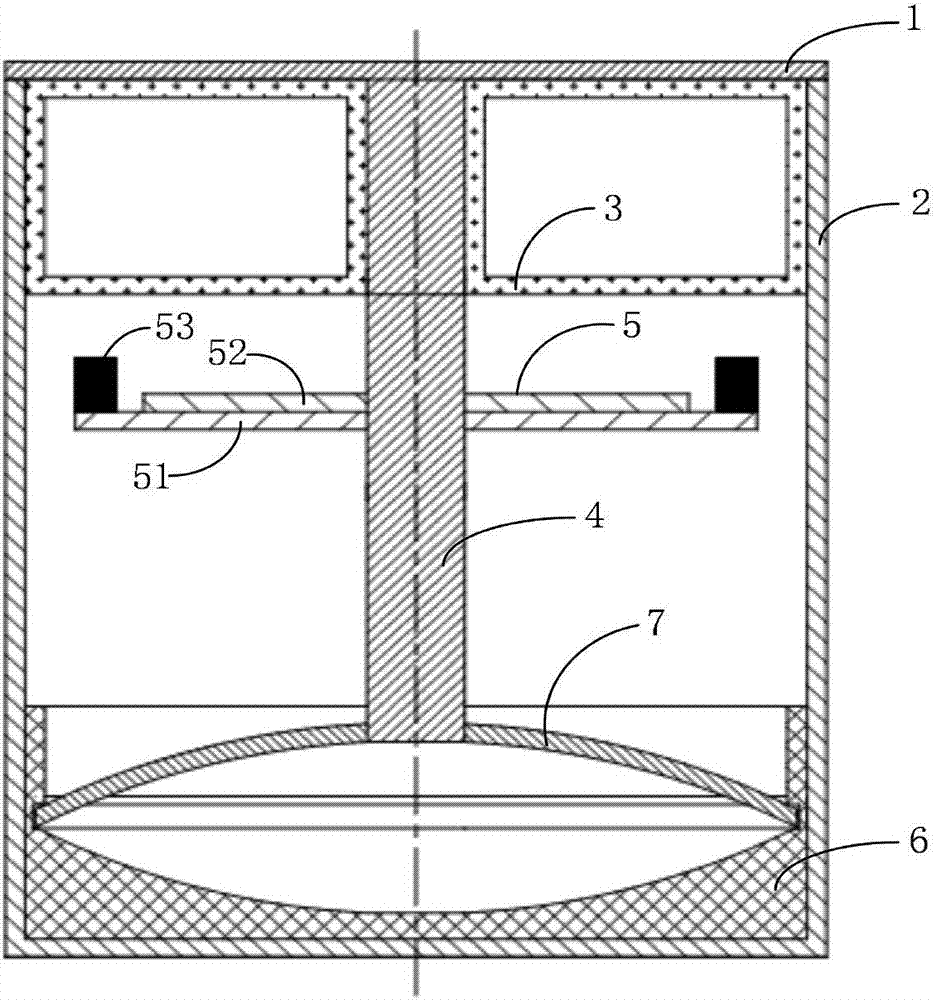

[0011] refer to figure 1 , figure 2 with image 3 , a vibration, temperature difference composite piezoelectric self-generating battery of the present invention comprises: battery top cover (1), battery casing (2), cooling box (3), heat conduction rod (4), piezoelectric cantilever beam (5), It is characterized in that it also includes a heat-absorbing base (6) and a disc-shaped thermal bimetal (7), wherein: the battery top cover (1) is a disc-shaped member, and an electrode is arranged in the center of the disc; the battery case (2) is a cylindrical member with a bottom, and an electrode is arranged in the middle of the outer surface of the bottom of the cylinder; the lower surface of the battery top cover (1) and the upper surface of the battery case (2) are welded to form a battery closed and sealed cavity; the cooling The box (3) is a ring-shaped shell, which is hollow and filled with cooling liquid inside; the upper surface of the cooling box (3) is bonded to the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com