Environment-friendly energy-saving multifunctional cleaning machine

An environmental protection and energy saving, washing machine technology, applied in road cleaning, cleaning methods, cleaning methods and utensils, etc., can solve problems such as reducing efficiency, increasing labor and time costs, and increasing time and effort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

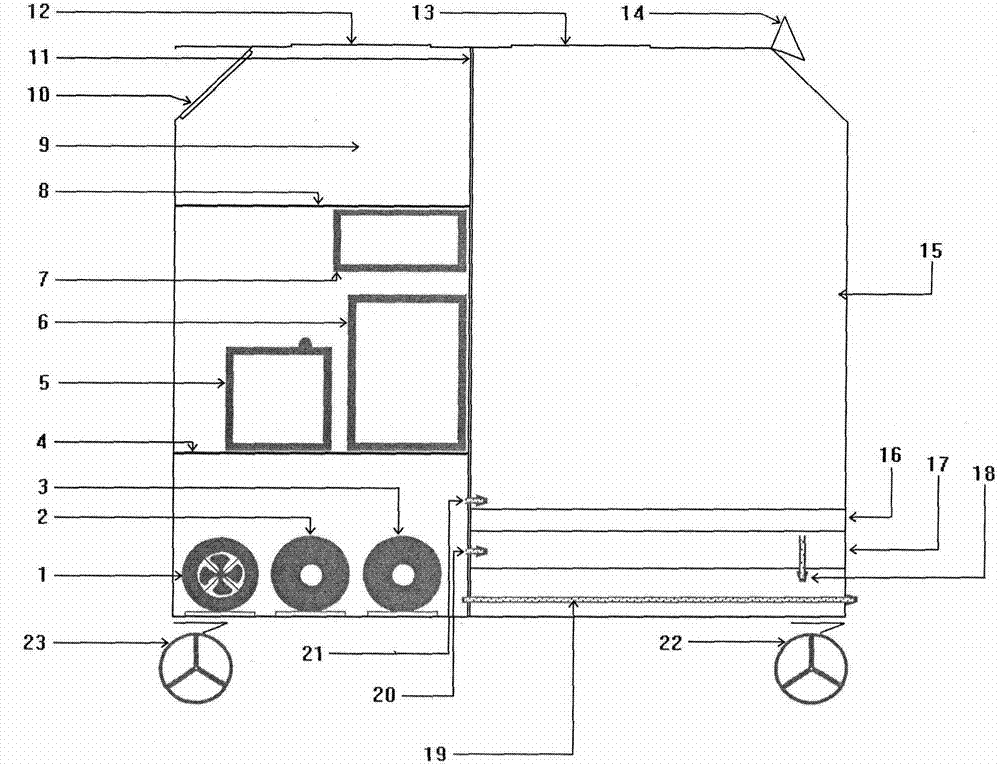

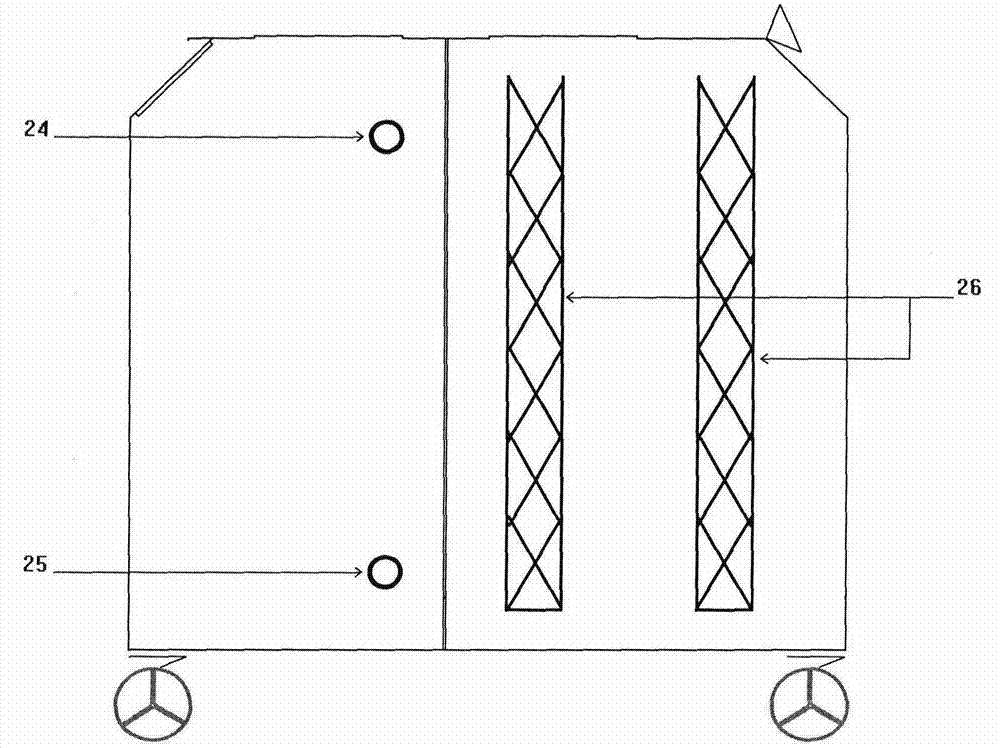

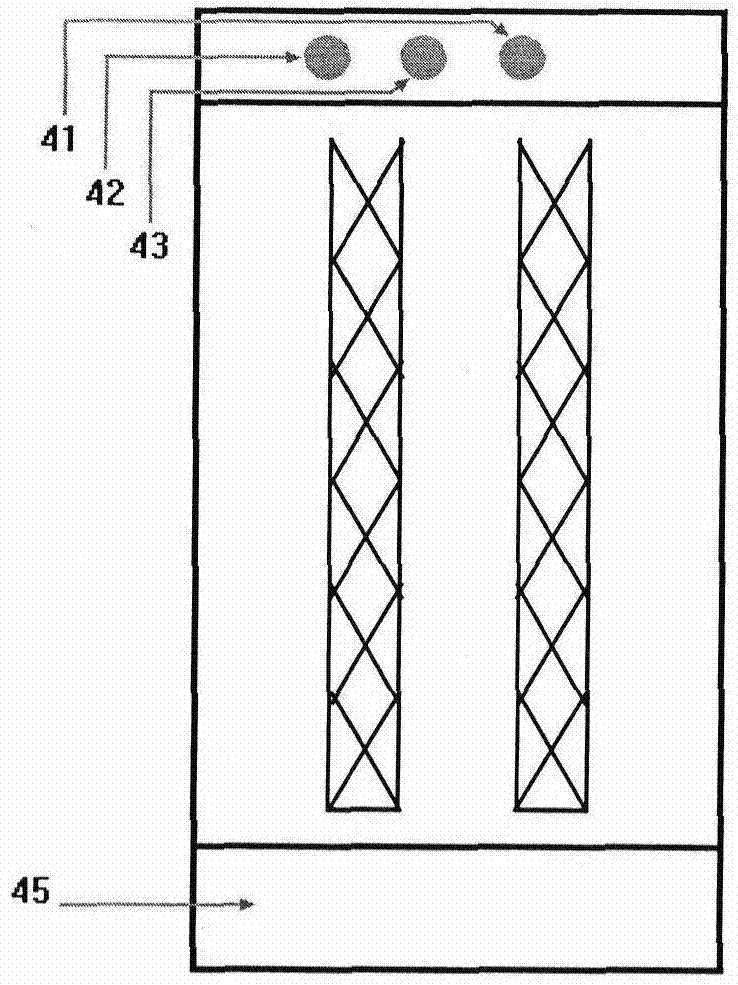

[0029] Embodiment 1, road guardrail cleaning, first connect the wheel mounting track on the left side of the guardrail cleaner with the wheel mounting track on the right side of the washing machine, and then connect the power inlet hole, air inlet hole, water inlet hole and pump sewage hole , the power inlet hole supplies power to the motor and the hot air column, the air inlet hole supplies air to the hot air column, the water inlet hole sends water to the high-pressure water nozzle, and the sewage pump hole pumps the sewage in the sewage storage tank of the guardrail cleaner to the cleaning machine through the sewage pump in the waste water tank. The DC power supply is divided into two circuits, one DC24v supply to the motor, one DC72v supply to the hot air column, and the guardrail cleaning operation can be carried out through the start button on the cleaning machine control panel. During the operation, the guardrail is placed between the roller brush and the hot air column...

Embodiment 2

[0030] Embodiment 2, clean the outer surface of the car, connect the water outlet with a high-pressure water gun, the DC 24V power supply is divided into two circuits, one is DC24v, and the other is converted to DC12v by a converter, and the intelligent control diaphragm pump can accept DC24v and DC12v two-way power supply. Through the linkage switch, one way of power supply and one way of cutting off are realized. When DC24v is powered, the diaphragm pump is intelligently controlled to generate high-pressure output water flow, and when DC12v is powered, the diaphragm pump is intelligently controlled to generate low-pressure output water flow. The traditional car washing industry uses a 220v water pump with a flow rate of 30-60L per minute to wash the car once and needs about 250L of water. The energy-saving car washing machine of the present invention uses DC 24v, 12v per minute flow rate between 5-15L to wash the car once, only 20 -35L water consumption.

Embodiment 3

[0031] Embodiment 3, cleaning of public transportation facilities, exhibition boards, and outdoor low-altitude facilities: connect with a high-pressure water gun through a multifunctional cleaning machine, and the nozzle of a high-pressure water gun discharges a water source of 10-16 kilograms of pressure in a fan shape, with a flow rate of 5-8L per minute Realize the function of high-pressure micro-water flushing between. In view of the phenomenon of serious dust accumulation or surface attachment, the function of dirty surface grinding can be realized by connecting the multi-function cleaning machine with the electric cleaning brush. The electric cleaning brush uses non-metallic abrasive brushes, and the cleaning process will not damage the surface of the cleaned object.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com