Elevator traction machine

A technology of elevator traction machine and casing, which is applied to elevators, elevators, transportation and packaging in buildings, etc. It can solve the problems of large impact force when stopping and stopping, coupling damage and impact, and reduction box impact, etc. problem, to achieve the effect of precise stop position, weakening impact and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

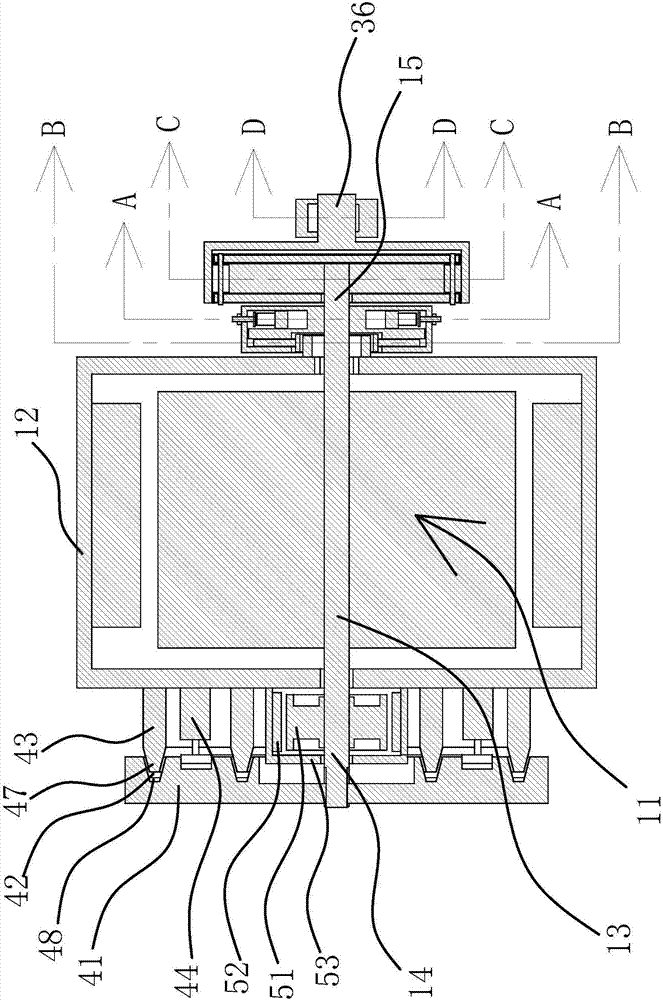

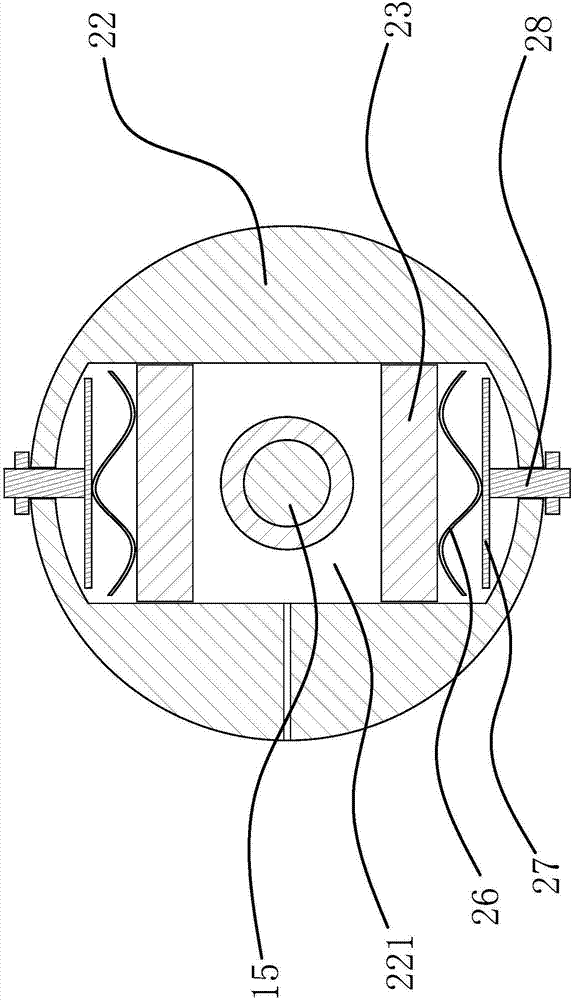

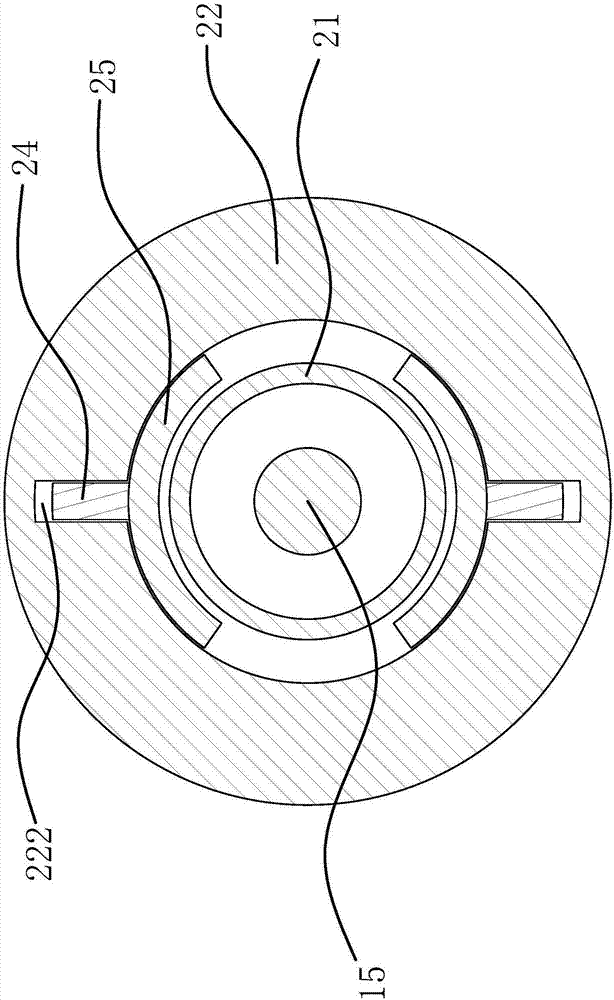

[0038] like figure 1 , figure 2 and image 3 As shown, the elevator traction machine includes a motor 11, a casing 12 and a rotating shaft 13 on the motor 11, a speed reducer and a brake are arranged between the casing 12 and the rotating shaft 13, and the rotating shaft 13 has a control end 14 protruding from the casing 12 and the output end 15, the output end 15 is provided with a passive safety device, the passive safety device includes a brake disc one 21 fixed on the casing 12 and a speed limiting box 22 fixed on the rotating shaft 13, and the speed limiting box 22 is evenly arranged There are several sliding chambers 221, each sliding chamber 221 is provided with a slidable counterweight valve core 23, and the hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com