Method for preparing light brown leather with washing function

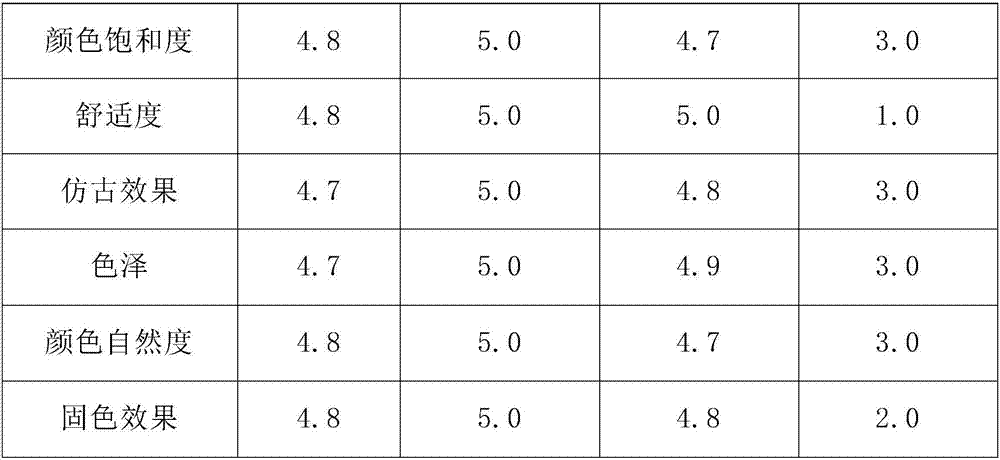

A technology for brown and leather materials, which is applied in the field of preparation of light brown leather materials, can solve the problems of not being able to repair the damage of the leather surface well, the color is disordered and not durable, and the coloring effect is not good, so as to achieve good color fixing effect and color Saturated, more natural colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A method for preparing dark brown leather with a washing function, the method comprising the following steps: a method for preparing light brown leather with a washing function, the method comprising the following steps: Step 1, changing the color of the leather embryo, by fully automatic The leather spraying machine sprays the dyeing agent evenly on the leather embryo;

[0021] Step 2: Change the color of the finished product. Firstly, place the treated skin embryo in step 1 inside the oil spraying table, and spray brown dye solution on the skin embryo. Agent A, the speed of the polishing machine is 19 rev / s at this time, and the finishing aid B is sprayed again, and the rotating speed of the polishing machine is 9 rev / s, and finally the finishing aid C is sprayed, and the speed of the polishing machine is now 9 revolutions / second.

[0022] The composition and parts by weight of the spray dyeing agent are 20 parts of metal complex, 10 parts of emulsifier, 20 parts of ...

Embodiment 2

[0028] A method for preparing light brown leather with a washing function, the method comprising the following steps: step 1, changing the color of the leather embryo, spraying a dyeing agent evenly on the leather embryo through a fully automatic skin spraying machine;

[0029] Step 2: Change the color of the finished product. Firstly, place the treated skin embryo in step 1 inside the oil spraying table, and spray brown dye solution on the skin embryo. Agent A, the speed of the polishing machine is 19 rev / s at this time, and the finishing aid B is sprayed again, and the rotating speed of the polishing machine is 9 rev / s, and finally the finishing aid C is sprayed, and the speed of the polishing machine is now 9 revolutions / second.

[0030] The composition and parts by weight of the spray dyeing agent are 30 parts of metal complexes, 15 parts of emulsifiers, 25 parts of synthetic resins, 10 parts of surfactants, 5 parts of auxiliary agents and 25 parts of environment-friendly ...

Embodiment 3

[0036] A method for preparing light brown leather with a washing function, the method comprising the following steps: step 1, changing the color of the leather embryo, spraying a dyeing agent evenly on the leather embryo through a fully automatic skin spraying machine;

[0037] Step 2: Change the color of the finished product. Firstly, place the treated skin embryo in step 1 inside the oil spraying table, and spray brown dye solution on the skin embryo. Agent A, the speed of the polishing machine is 19 rev / s at this time, and the finishing aid B is sprayed again, and the rotating speed of the polishing machine is 9 rev / s, and finally the finishing aid C is sprayed, and the speed of the polishing machine is now 9 revolutions / second.

[0038] The composition and parts by weight of the spray dyeing agent are 40 parts of metal complexes, 20 parts of emulsifiers, 30 parts of synthetic resins, 15 parts of surfactants, 10 parts of auxiliary agents and 30 parts of environment-friendly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com