Preparation method of polished brown leather

A technology of brown and leather materials, which is applied in the field of preparation of shaving brown leather materials, which can solve the problems of uneven coloring, lack of antique, unnatural brightness, etc., and achieve the effect of good color fixing effect, good comfort and saturated color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

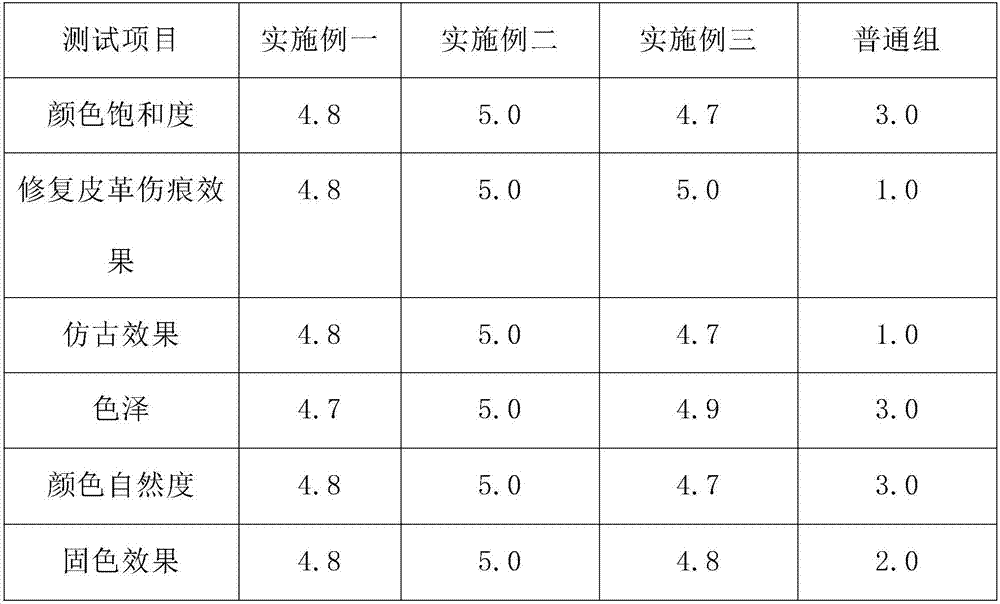

Examples

Embodiment 1

[0019] A preparation method of brown leather for repairing face, the method comprises the following steps: step 1, changing the color of the leather embryo, first placing the leather embryo to be processed on a surface grinding machine, using No. 120 sandpaper to grind the surface, and then grinding the surface After that, put the skin embryo on the automatic skin spraying machine, spray the dyeing solution evenly on the skin embryo, and finally put the sprayed skin embryo into the washing machine, and add softener, color fixing agent and water, wash in a washing machine for 15 minutes, take out the washed skin embryo and place it in a dryer, dry it in the dryer for 10 minutes, and take out the skin embryo;

[0020] Step 2. To change the color of the finished product, firstly put the processed skin embryo in step 1 into the polishing machine, apply the medium gloss shoe cream on the leather embryo through the polishing machine, and then apply the finishing aid A after applying ...

Embodiment 2

[0026] A preparation method of brown leather for repairing face, the method comprises the following steps: step 1, changing the color of the leather embryo, first placing the leather embryo to be processed on a surface grinding machine, using No. 120 sandpaper to grind the surface, and then grinding the surface After that, put the skin embryo on the automatic skin spraying machine, spray the dyeing solution evenly on the skin embryo, and finally put the sprayed skin embryo into the washing machine, and add softener, color fixing agent and water, wash in a washing machine for 18 minutes, take out the washed skin embryo and place it in a dryer, dry it in the dryer for 13 minutes, and take out the skin embryo;

[0027] Step 2. To change the color of the finished product, firstly put the processed skin embryo in step 1 into the polishing machine, apply the medium gloss shoe cream on the leather embryo through the polishing machine, and then apply the finishing aid A after applying ...

Embodiment 3

[0033] A preparation method of brown leather for repairing face, the method comprises the following steps: step 1, changing the color of the leather embryo, first placing the leather embryo to be processed on a surface grinding machine, using No. 120 sandpaper to grind the surface, and then grinding the surface After that, put the skin embryo on the automatic skin spraying machine, spray the dyeing solution evenly on the skin embryo, and finally put the sprayed skin embryo into the washing machine, and add softener, color fixing agent and water, wash in a washing machine for 20 minutes, take out the washed skin embryo and place it in a dryer, dry it in the dryer for 15 minutes, and take out the skin embryo;

[0034] Step 2. To change the color of the finished product, firstly put the processed skin embryo in step 1 into the polishing machine, apply the medium gloss shoe cream on the leather embryo through the polishing machine, and then apply the finishing aid A after applying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com