A simple and convenient digital direct-injection printing and dyeing method without steaming and washing

A digital direct-injection, wash-free technology, applied in the field of printing and dyeing, can solve the problems of easy fading or fading, insufficient color fixation of textiles, poor wearing comfort of fabrics, etc., to achieve favorable development, easy to widely popularize and apply, and dyeing effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

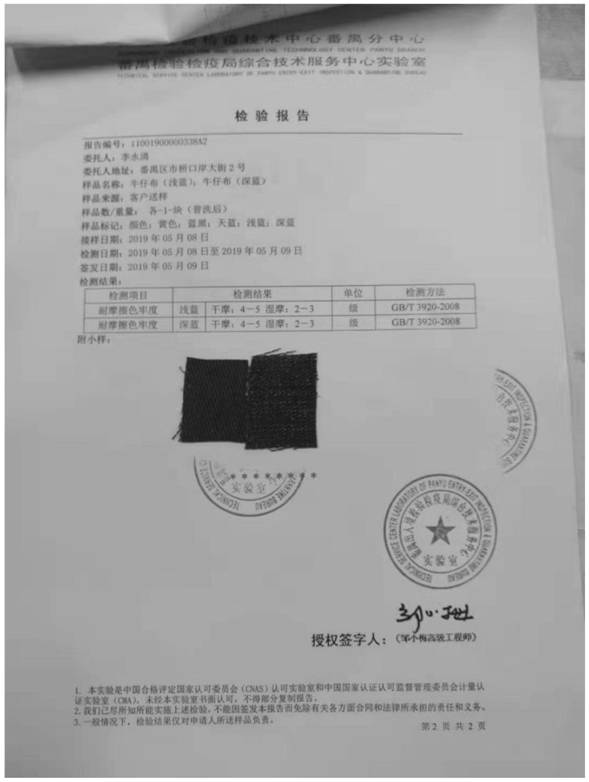

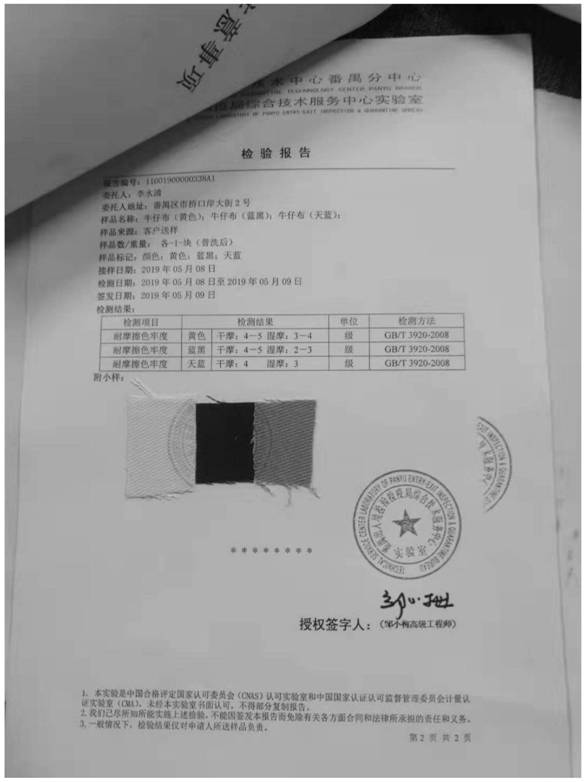

Image

Examples

Embodiment 1

[0056] A non-steaming, non-washing inkjet ink and a printing and dyeing method, wherein the components of the printing and dyeing ink are: dye 5-10%, ethylene glycol 8-10%, diethylene glycol 8-10%, glycerin 5% by weight ~6%, anti-staining salt K 0.1~1%, sodium carbonate 0.1~0.5%, sodium sulfate 0.1~2%, urea 0.1~1%, sodium bicarbonate 0.1~3%, sodium hexametaphosphate 0.1~1%, The balance is deionized water.

[0057] The inkjet ink modifier is composed of triethylenediamine, tripropyldiamine, N,N-dimethylhydrazine, N-methylcyclobutylamine and polyethyleneimine, and its mass ratio is 1:1:1: 1:1 with a pH of 9.

[0058] Taking denim as an example, the specific printing and dyeing process is as follows:

[0059] S1. Before the denim fabric is printed and dyed, the aqueous solution of the inkjet ink modifier is soaked and treated to form a modified layer on the surface of the fabric. After the treatment, the denim fabric has a liquid content of 50% and is dried;

[0060] S2. Then ...

Embodiment 2

[0066] A non-steaming, non-washing inkjet ink and printing and dyeing method, wherein the printing and dyeing ink is the same as that of Embodiment 1, and the specific printing and dyeing process is the same as that of Embodiment 1. The sexual agent is composed of tripropyldiamine, N,N-dimethylhydrazine, N-methylcyclobutylamine and polyethyleneimine, and its mass ratio is 1:1:1:1, and its pH is 9.

[0067] The denim fabric after printing and dyeing, then the effect is good, the color is saturated, the color does not fade after washing, and the color is fast.

Embodiment 3

[0069] A non-steaming, non-washing inkjet ink and a printing and dyeing method, wherein the components of the printing and dyeing ink are: dye 5-10%, ethylene glycol 8-10%, diethylene glycol 8-10%, glycerin 5% by weight ~6%, anti-staining salt K 0.1~1%, sodium carbonate 0.1~0.5%, sodium sulfate 0.1~2%, urea 0.1~1%, sodium bicarbonate 0.1~3%, sodium hexametaphosphate 0.1~1%, Deionized water balance.

[0070] The inkjet ink modifier is composed of triethylenediamine, tripropyldiamine, N,N-dimethylhydrazine, N-methylcyclobutylamine and polyethyleneimine, and its mass ratio is 0.5:0.5:0.5: 0.5:1 with a pH of 8.

[0071] Taking knitted fabric as an example, the specific printing and dyeing process is as follows:

[0072] S1. Before printing and dyeing, the knitted fabric is soaked with the aqueous solution of the above-mentioned inkjet ink modifier, and a modified layer is formed on the surface of the fabric. After the treatment, the knitted fabric has a liquid content of 50% and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com