An automatic feeding system for the top hopper of the tank furnace

A technology for automatic feeding and pot furnaces, which is applied in the direction of furnaces, furnace components, lighting and heating equipment, etc., to achieve the effects of improving automation, reducing labor costs, and highly targeted applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

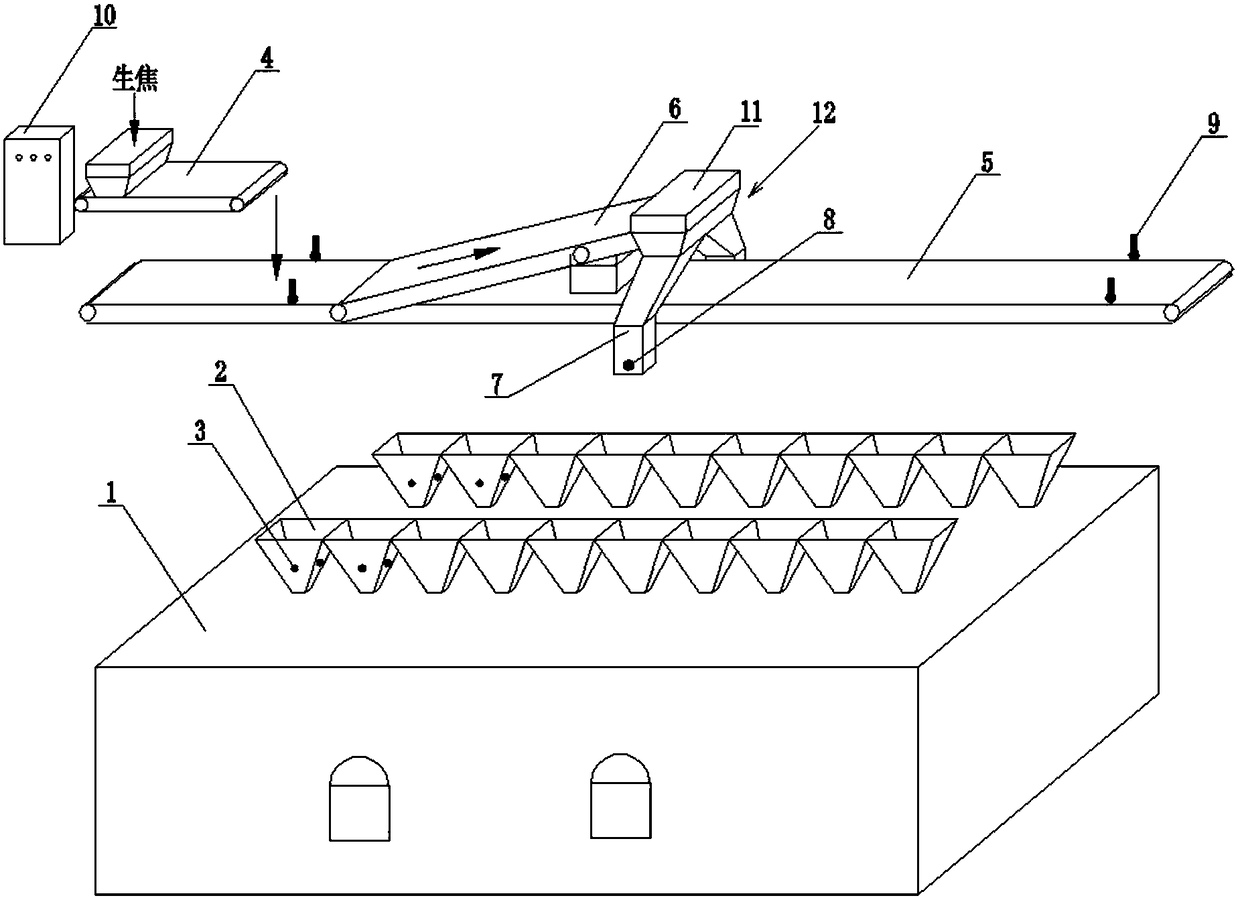

[0027] The present invention will be further described below in conjunction with accompanying drawing.

[0028] Such as figure 1 As shown, the automatic feeding system of the tank furnace top hopper of the present invention mainly includes: in the figure: tank furnace furnace body 1, furnace top hopper 2, material level switch 3 (eight units), quantitative feeder 4, conveyor belt 5. Trolley conveyor belt 6, feeding chute 7 (two), flow switch (two) 8, limit switch 9 (four), control box 10, trolley trough 11, feeding trolley 12, etc., specific structure as follows:

[0029] Two rows of furnace top hoppers 2 are installed on the top of the retort furnace body 1, and the number of furnace top hoppers 2 varies according to the size of the retort furnace. The material level switch 3 is installed on the two adjacent side walls of the furnace top hopper 2, because the tank furnace has a specific discharge cycle, so the material level switch 3 only needs to be installed on the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com