Annular hot-liquid-jet scale cleaning device for barrel body, and cleaning process thereof

A cleaning device and jetting technology, applied in the direction of liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of low efficiency, unsatisfactory cleaning effect, and no recovery of acidic solution, etc., and achieve structural unique effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation will be described below in conjunction with the accompanying drawings.

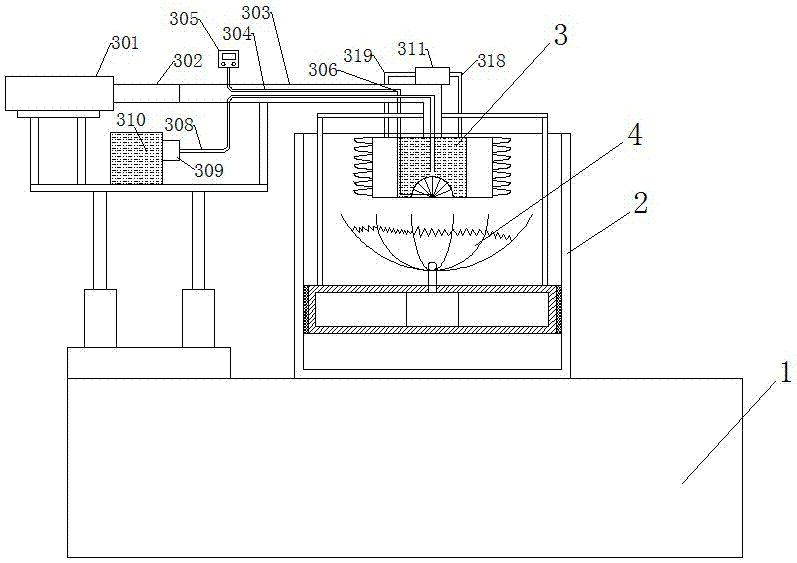

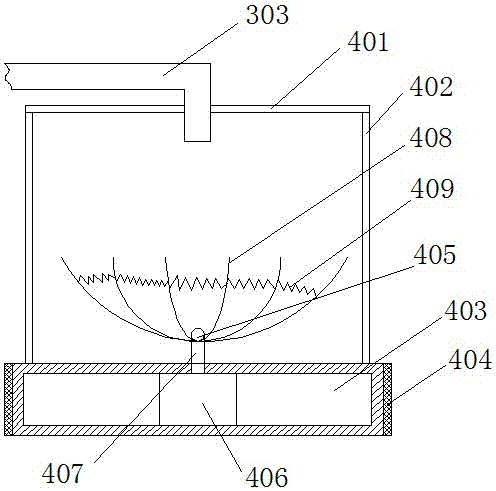

[0025] Such as figure 1 As shown, a ring-direction thermal liquid injection type cylinder fouling cleaning device includes a reaction tank 1, an exhaust cylinder 2, and a central heating annular injection unit 3. The upper part of the reaction tank 1 is connected to the exhaust cylinder 2, A central heating annular injection unit 3 is arranged above the exhaust cylinder 2 .

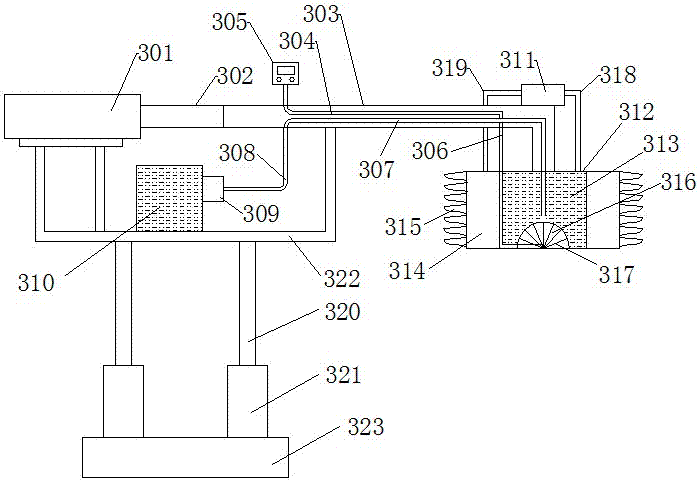

[0026] As shown in Fig. 2, the central heating annular injection unit 3 includes a first hydraulic cylinder 301, a first push rod 302, a hollow pipe 303, a horizontal wire pipe 304, a heating controller 305, a vertical wire pipe 306, Acid delivery pipe 307, acid delivery pipe 308, quantitative pump 309, waste acid storage tank 310, booster pump 311, spray tank 312, acid chamber 313, spray chamber 314, S-shaped nozzle 315, heating chamber 316, pump Acid pipe 318 , acid inlet pipe 319 , support fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com