Profile-cutting device capable of automatic feeding and discharging

A technology for feeding and discharging materials and profiles, which is applied in the direction of grinding feed movement, grinding machine parts, grinding workpiece supports, etc. It can solve the problems of complicated operation, low work efficiency, and failure to meet production requirements, etc., and achieves convenient use. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

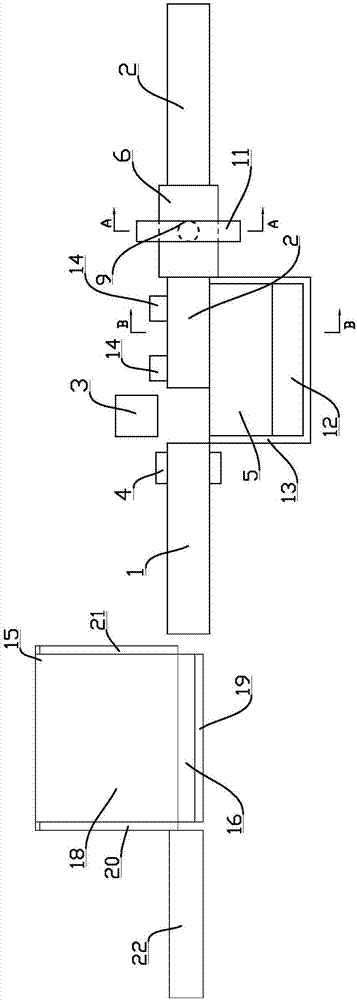

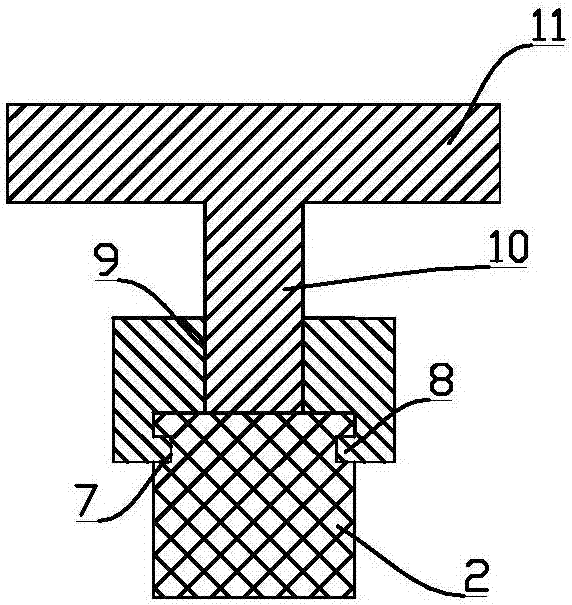

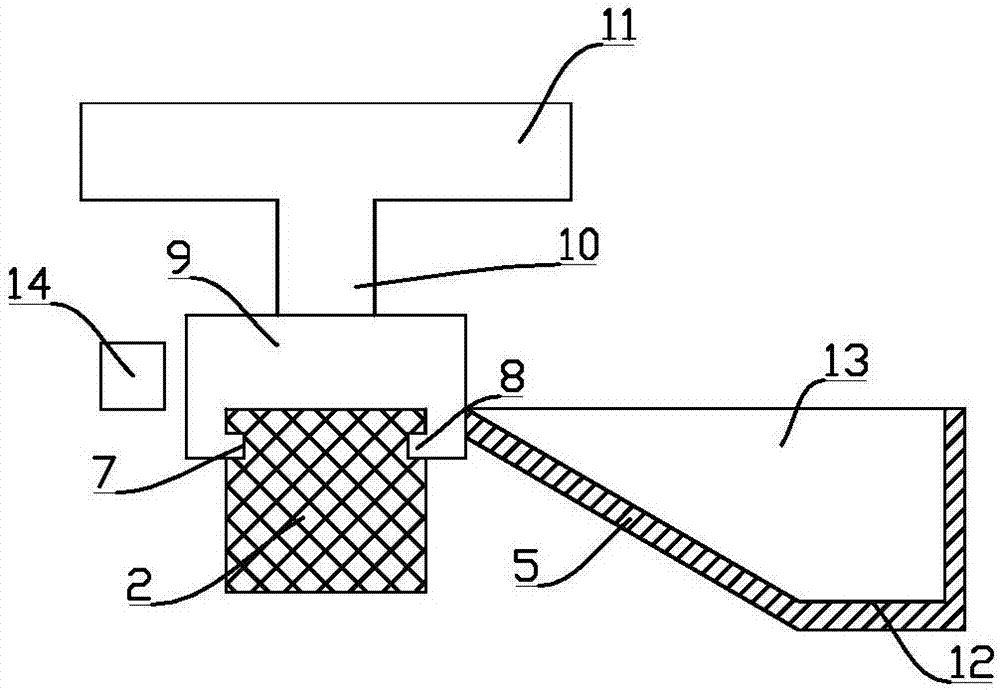

[0017] Such as Figure 1-5 As shown, a profile cutting device for automatic feeding and discharging includes a front support platform 1 and a rear support platform 2 for placing profiles. The front support platform 1 and the rear support platform 2 are fixed on the same straight line, and the front support platform 1 and the rear support platform 2 with a gap, and the grinding wheel cutting machine 3 arranged between the front support platform 1 and the rear support platform 2, the discharge rack at the side of the rear support platform 2, the front part of the front support platform 1 Feeding device, the end of the front support platform 1 close to the grinding wheel cutter 3 is provided with a clamping device 4 for clamping profiles, and the upper part of the rear support platform 2 is provided with a limit slide that slides along the rear support platform 2 Block 6, a pair of chute 7 is provided on both sides of the rear support platform 2, a pair of protrusions 8 matching ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com