Width grinding system capable of realizing automatic feeding and achieving method thereof

A technology of automatic feeding and width, which is used in grinding devices, grinding machine tools, metal processing equipment, etc., can solve the problems that the width and height of conveying power products are not applicable, are not suitable for manual feeding, and are prone to jamming. The transmission power is sufficient, the structure is simple, and the cost is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

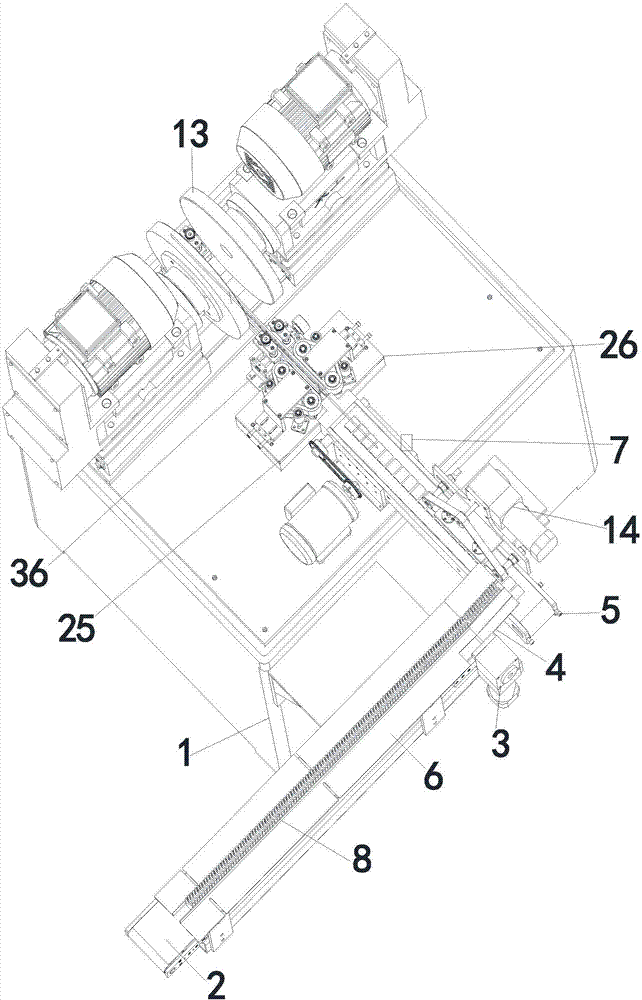

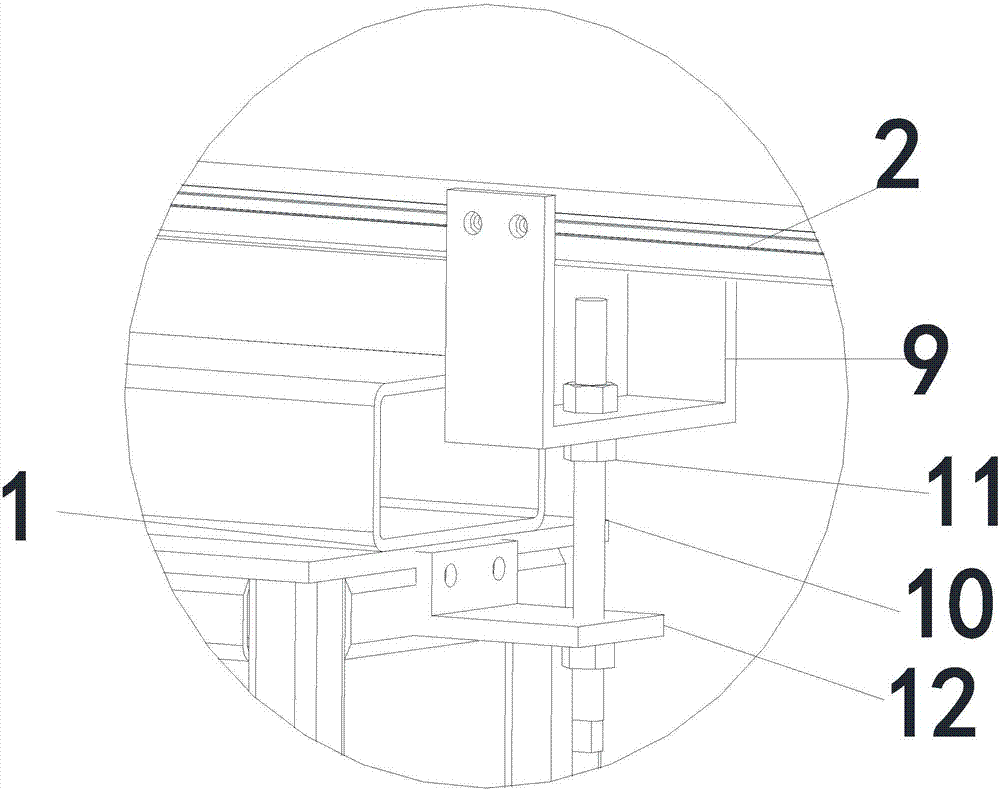

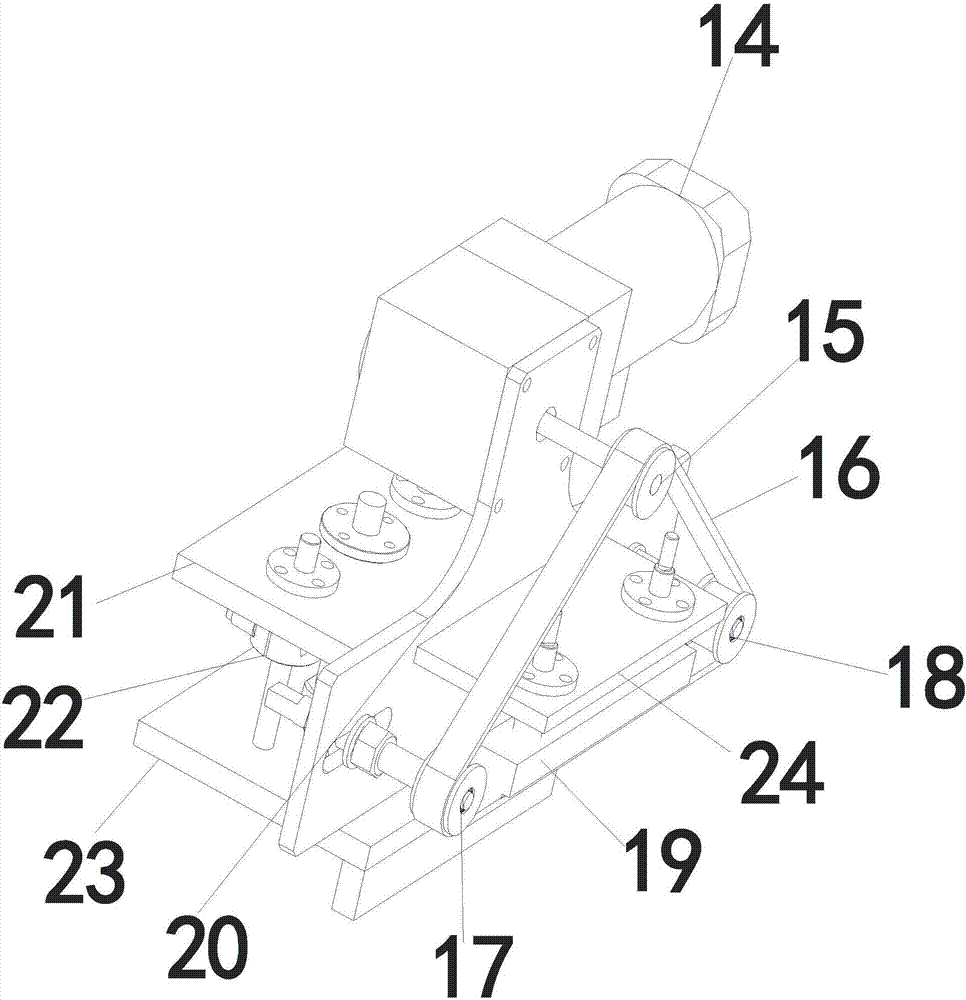

[0039] Such as Figure 1~6 As shown, an automatic feeding width grinding system includes a frame, and a feeding conveyor belt is arranged above the frame. The feeding conveyor belt is driven by a feeding conveyor belt motor. The upslope board is inclined, and the discharge conveyor belt is installed under the upslope board; the side of the discharge conveyor belt is equipped with a magnetic tile pressurized conveying device, and the outlet end of the discharge conveyor belt is provided with a magnetic tile feeding conveying device. The front end of the magnetic tile feeding and conveying device is equipped with a magnetic tile adjusting device, and the outlet end of the magnetic tile adjusting device is a width grinder.

[0040] Both sides of the feed conveyor belt in this embodiment are respectively provided with adjustable baffles, which are adjusted through the adjustment screws below; the motor of the feed conveyor belt is a speed-regulating motor; ° Angle; the lower side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com