Adhesive sheet, display, and method for producing same

A display, adhesive sheet technology, applied in chemical instruments and methods, adhesives, adhesive types, etc., can solve problems such as light reflection loss, and achieve the effects of high film strength, step followability and excellent foaming resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

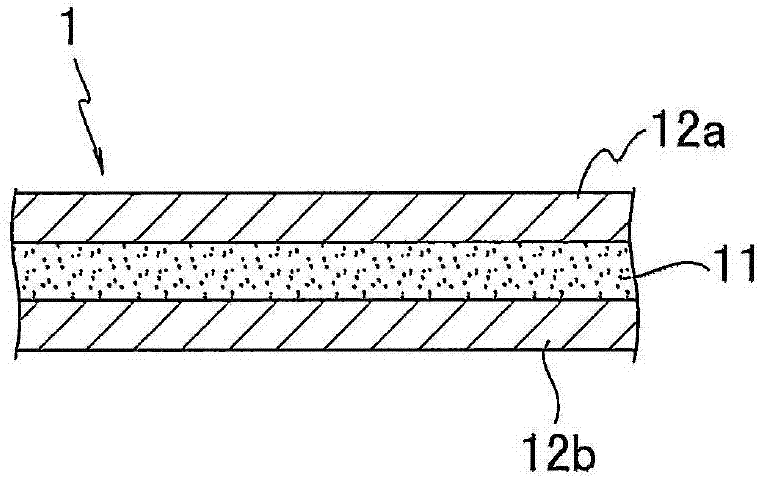

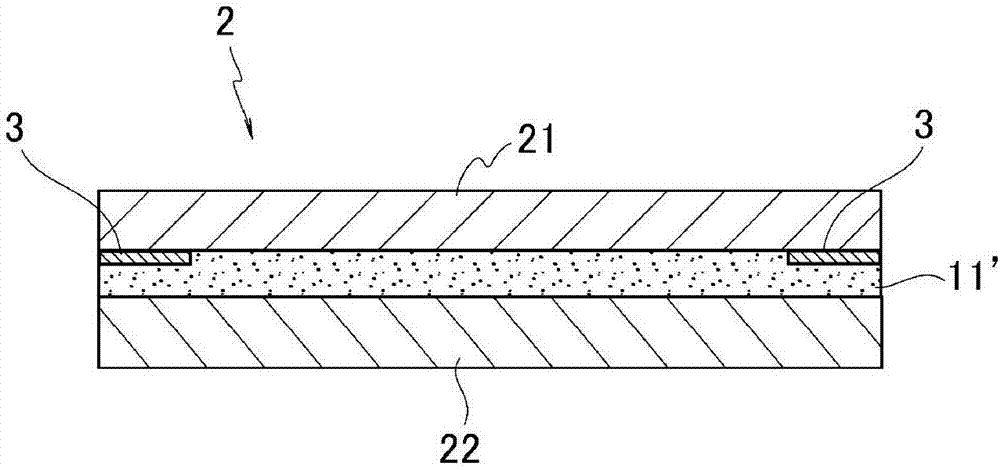

Image

Examples

preparation example Construction

[0098] (7) Preparation of adhesive composition

[0099] Adhesive composition P is the preparation of (meth)acrylate copolymer (A), after the obtained (meth)acrylate copolymer (A), thermal crosslinking agent (B), ultraviolet curable component ( C) and a photopolymerization initiator (D) are mixed, and it can also prepare by adding a silane coupling agent (E) and / or an additive as needed.

[0100] The (meth)acrylate copolymer (A) can be produced by polymerizing a mixture of monomers constituting a polymer by a normal radical polymerization method. The polymerization of a (meth)acrylate copolymer (A) can be performed by a solution polymerization method etc. using a polymerization initiator as needed. Examples of the polymerization solvent include ethyl acetate, n-butyl acetate, isobutyl acetate, toluene, acetone, hexane, methyl ethyl ketone, and the like, and two or more of them may be used in combination.

[0101] As a polymerization initiator, an azo compound, an organic pero...

Embodiment 1

[0154] 1. Preparation of (meth)acrylate copolymer

[0155] Copolymerization of (meth)acrylates was prepared by copolymerizing 60 parts by mass of 2-ethylhexyl acrylate, 10 parts by mass of isobornyl acrylate, 10 parts by mass of N-acryloylmorpholine, and 20 parts by mass of 2-hydroxyethyl acrylate. Object (A). When the molecular weight of this (meth)acrylate copolymer (A) was measured using the method mentioned later, the weight average molecular weight (Mw) was 500,000.

[0156] 2. Preparation of Adhesive Composition

[0157] 100 parts by mass of the (meth)acrylate copolymer (A) obtained in the above step 1 (solid content conversion value; hereinafter the same), trimethylolpropane-modified toluene diisocyanate as a thermal crosslinking agent (B) 0.2 parts by mass, 5.0 parts by mass of ε-caprolactone-modified tris(2-acryloyloxyethyl)isocyanurate as the ultraviolet curable component (C), 2 , 0.5 parts by mass of 4,6-trimethylbenzoyl-diphenyl-phosphine oxide, and 3-glycidoxyp...

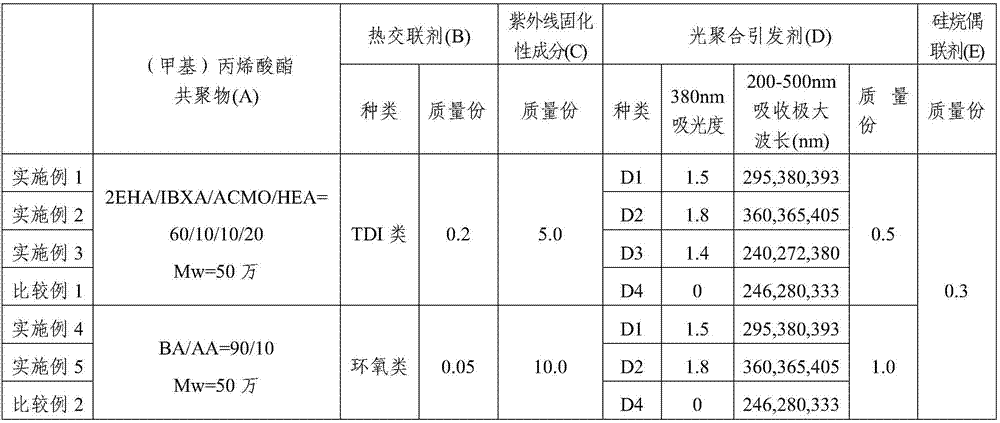

Embodiment 2~5、 comparative example 1~2

[0178] In addition to the type and ratio of each monomer constituting the (meth)acrylate copolymer (A), the type and amount of the thermal crosslinking agent (B), the compounding amount of the ultraviolet curable component (C), and the photopolymerization The kind and compounding quantity of the initiator (D) were changed as shown in Table 1, and it carried out similarly to Example 1, and produced the adhesive sheet.

[0179] Here, the above-mentioned weight average molecular weight (Mw) is a standard polystyrene-equivalent weight average molecular weight measured (GPC measurement) under the following conditions using gel permeation chromatography (GPC).

[0180]

[0181] · GPC measurement device: HLC-8020, manufactured by TOSOH;

[0182] · GPC column (passed in the following order): manufactured by TOSOH

[0183] TSK guard column HXL-H

[0184] TSK gel GMHXL (×2)

[0185] TSK gel G2000HXL;

[0186] Determination of solvent: tetrahydrofuran;

[0187] · Measurement tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com