Splash-proof dust-removing device for molten iron ditch slot

A technology of dust removal device and iron gutter, applied in the direction of dust collector, discharge device, etc., can solve the problems of poor working environment, unfavorable health of workers, and large environmental impact, so as to prevent strong light pollution, facilitate docking, and solve heat radiation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

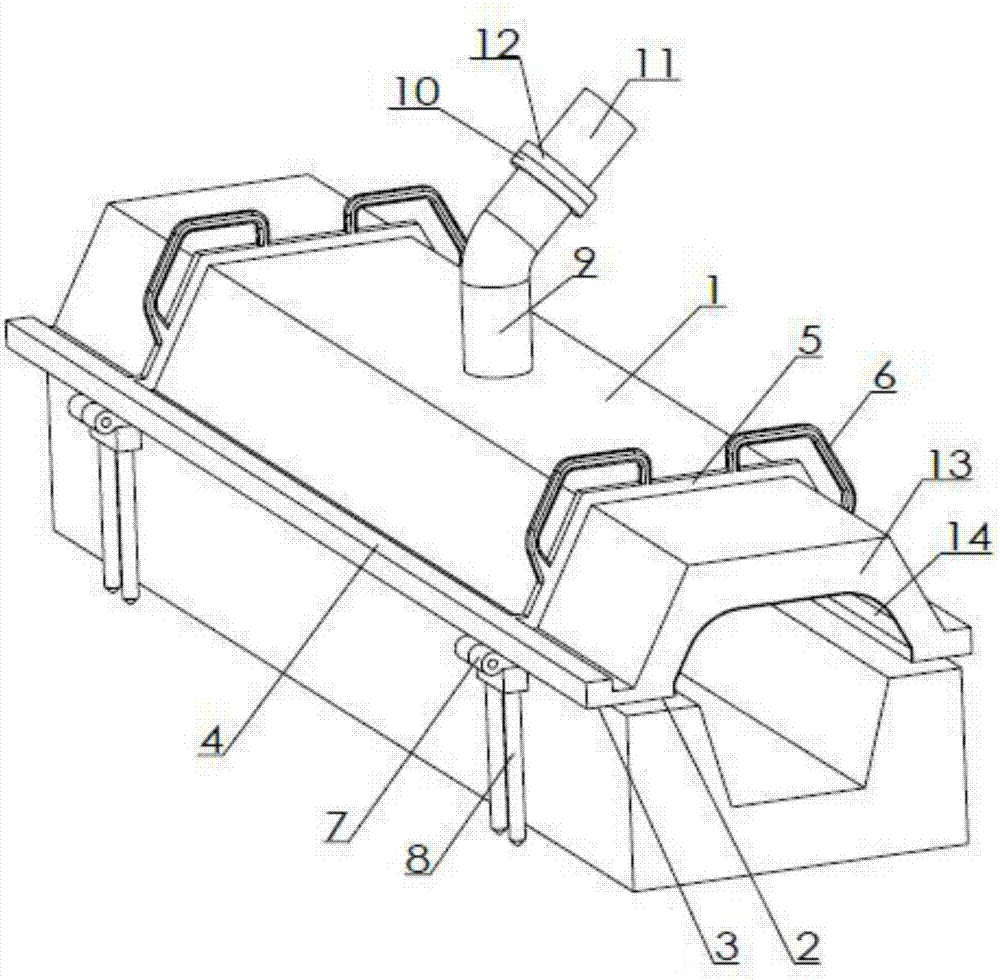

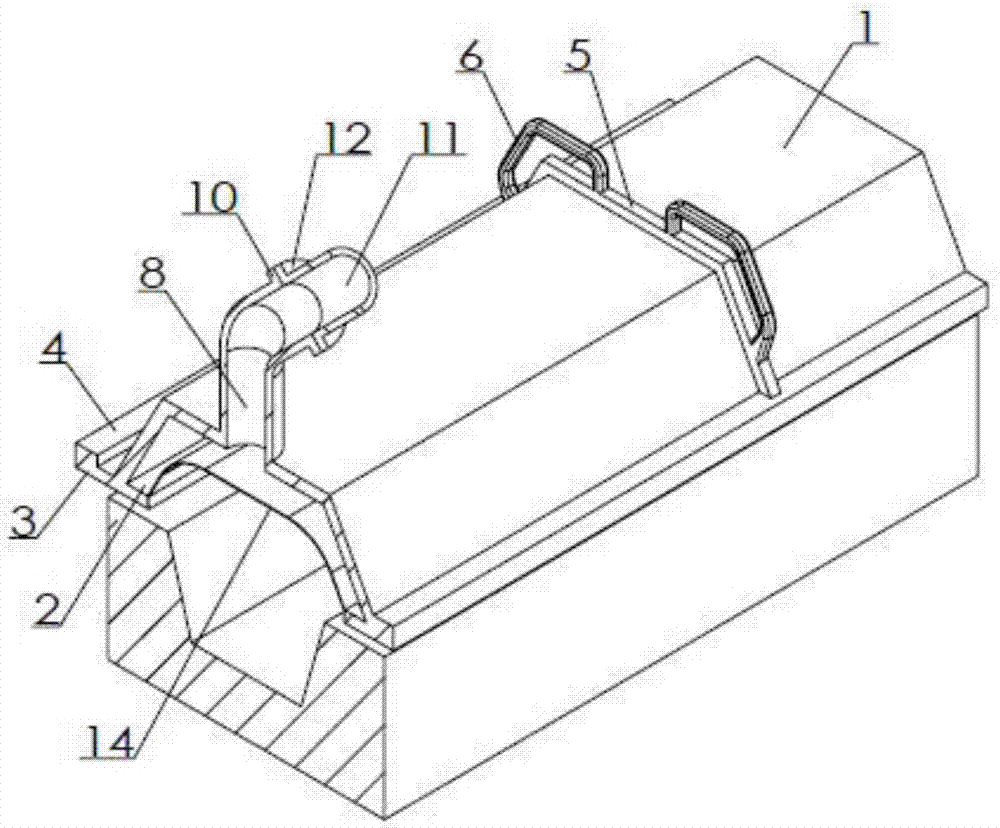

[0011] Examples of the present invention figure 1 , 2 As shown, the splash-proof and dust-removing device for the molten iron groove is provided with the molten iron groove and at least one section of the splash-proof cover, which can be arranged on the upper part of the molten iron groove in multiple sections to keep gaps, even for curved grooves, and the splash-proof cover is provided with The section extending along the iron launder is an inverted U-shaped outer cover 1 as a whole. The lower edges on both sides of the outer cover are respectively connected with inner edges 2 and outer edges 3, and the two outer edges are respectively connected with longitudinal side beams 4. At least two longitudinal side beams pass between the two longitudinal side beams. A roughly inverted U-shaped crossbeam 5 connected to the outer side of the outer cover is connected, and a wrench 6 is connected on the scale to form a structurally stable support. Stretch upwards and then to the exhaust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com