Lip seal ring and its plug valve

A technology of lip seal ring and plug valve, which is applied in the direction of engine seal, cock including cut-off device, valve device, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

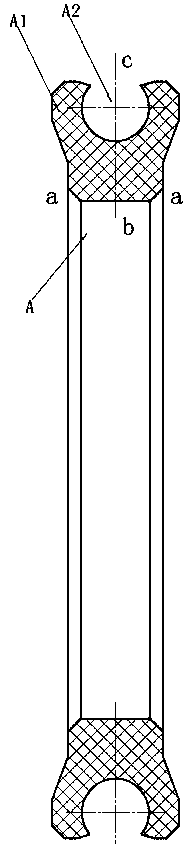

[0037] Lip seal ring, its structure is as follows figure 1 As shown, it includes an annular seal ring body A, the lip A1 of the lip seal ring is located on the two sides a of the seal ring body A, and a lip A2 opening toward the outer diameter side c of the seal ring body A is formed between the two lips A1.

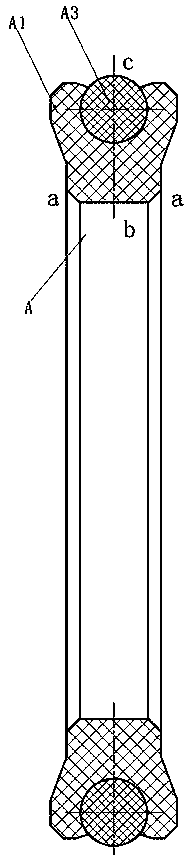

[0038] In another embodiment, based on figure 1 The structure of the lip seal ring, the lip A2 is equipped with a support ring A3, such as figure 2 shown.

Embodiment 2

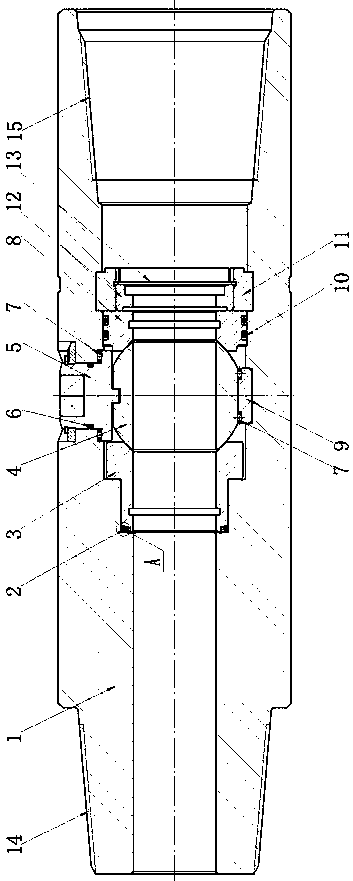

[0040] Plug valve of the present invention, its structure is as image 3 As shown, including valve body 1, lower valve seat 3, valve core 4, upper valve seat 8 and valve stem 5; lower valve seat 3, valve core 4, upper valve seat 8 pass through the end of upper valve seat 8 (valve body 1 Inside) the split buckle 11, buckle 12 and retaining ring 13 are positioned and assembled in the valve body 1. In addition, the valve stem 5 is assembled on the valve core 4 by means of an adapted keyway and key. One end of the valve body 1 is a male buckle 14, and the other end is a female buckle 15 to connect the nozzle. In this embodiment, the male buckle 14 is located at the end of the lower valve seat 3, and the female buckle 15 is located at the end of the upper valve seat 8. .

[0041] In the plug valve of the present invention, a first sealing member 2 is arranged between the lower valve seat 3 and the assembly surface of the valve body 1. In the present invention, the first sealing m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com