Combustion test bed for a gas turbine, combustion test control method and apparatus

A technology of combustion test and test section, which is applied in the direction of gas turbine engine test, internal combustion engine test, jet engine test, etc. It can solve the problems of reducing the accuracy of test results and the high power consumption of electric heaters, so as to achieve reasonable use of flue gas waste heat and save energy. Energy, effects that improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to change the air temperature working conditions of the equipment in the test section, thereby saving energy and improving the accuracy of test results, the embodiment of the present invention provides a combustion test bench for a gas turbine, a combustion test control method and a device. In order to make the purpose, technical solution and advantages of the present invention clearer, the following examples are given to further describe the present invention in detail.

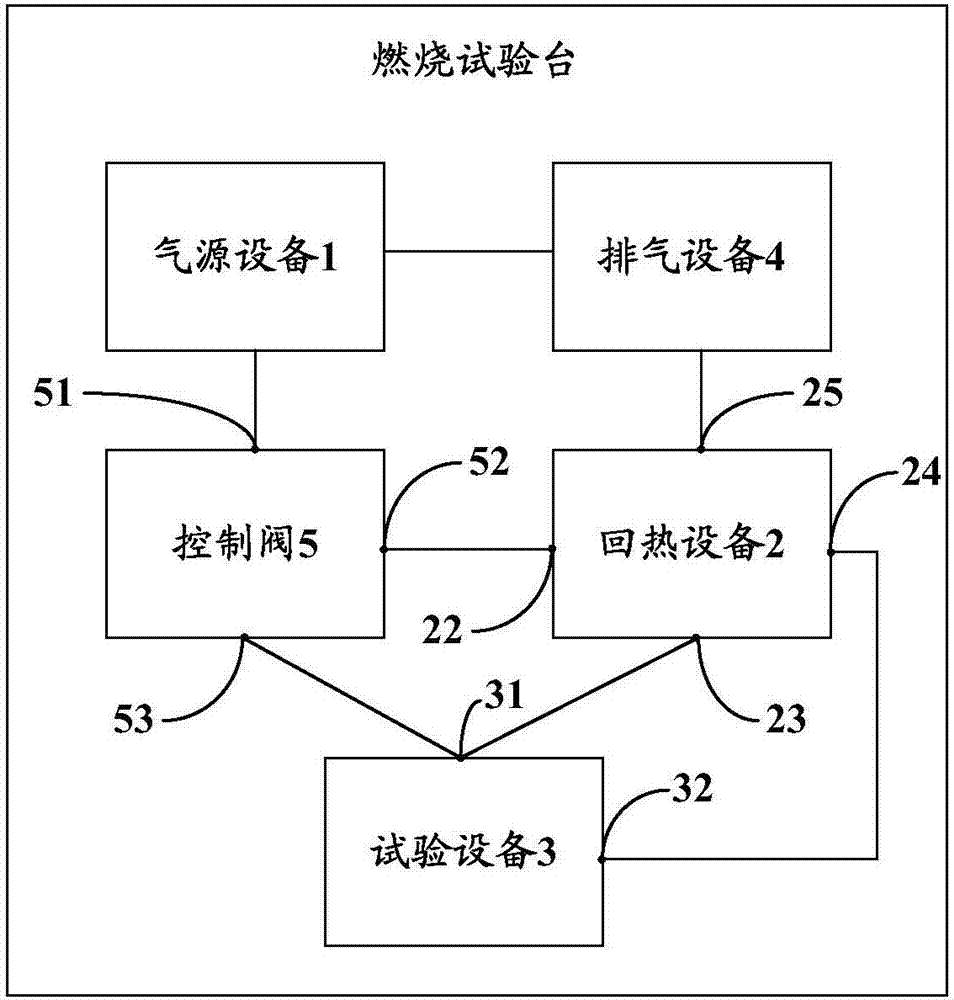

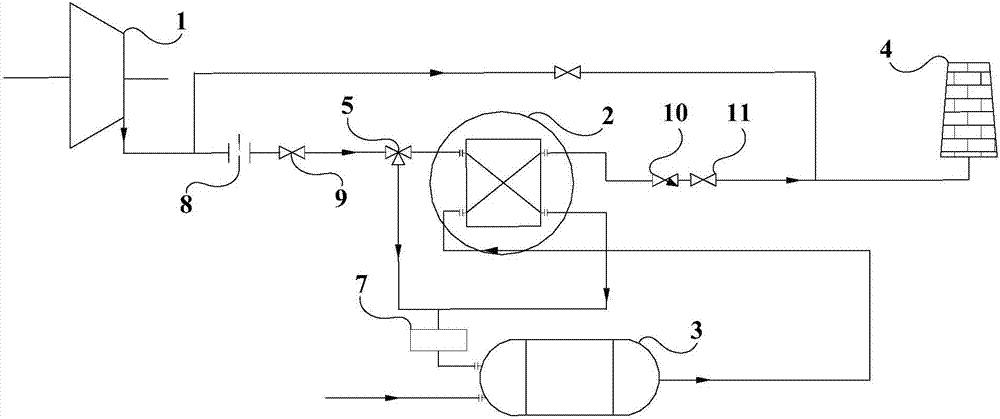

[0049] Such as figure 1 As shown, the embodiment of the present invention provides a combustion test bench for a gas turbine, including a gas source device 1, a heat recovery device 2, a test section device 3, an exhaust device 4 and a control valve 5, wherein:

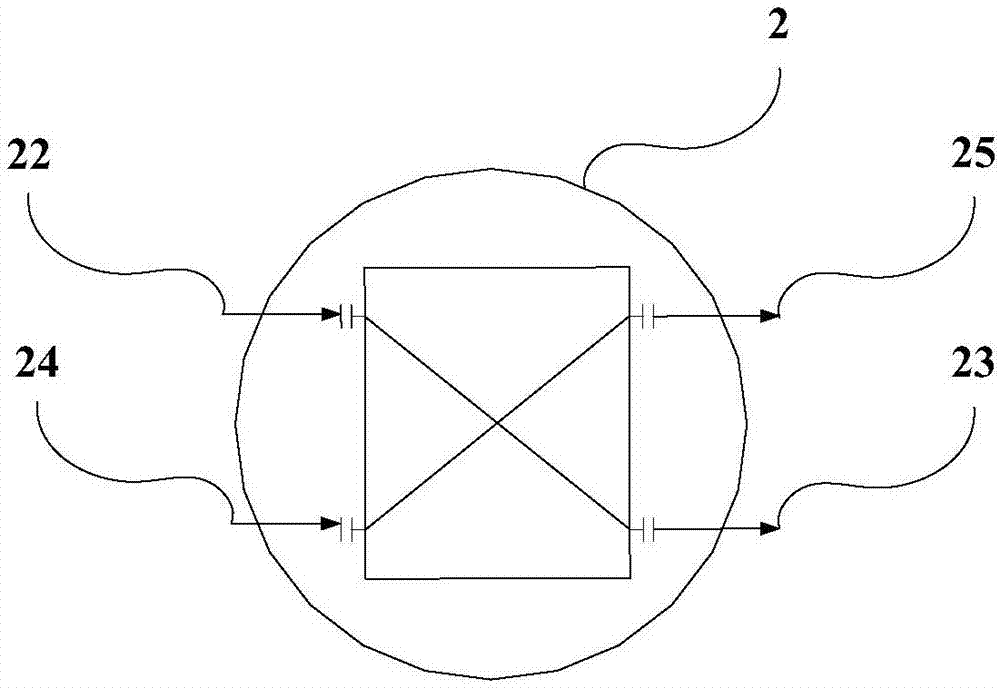

[0050] The test section equipment 3 includes an air inlet 31 and an exhaust outlet 32; the heat recovery equipment 2 includes an air inlet 22 communicated with the air source equipment 1, an air outlet 23 communicated with the air in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com