Cable 'disc-fixing and scale-fixing' laying system

A cable laying and cable technology, which is applied in the field of cable "fixed plate and fixed length" laying system, can solve problems such as improper laying management, excessive single project cost, and large laying waste, so as to promote cable supply and prevent actual supply jumps code effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

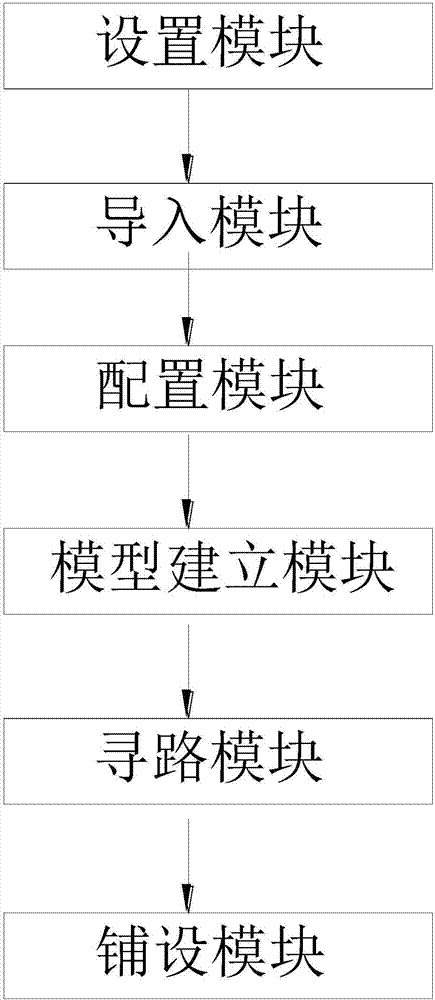

[0020] A cable "fixed plate and fixed length" laying system is characterized in that it includes:

[0021] The setting module is used to set related parameters such as the model of cable laying;

[0022] The import module is used to import equipment location information and 3D bridge information and cable inventory information established by 3D design software;

[0023] The configuration module is used to match the bridge number in the three-dimensional bridge information with the bridge type in the database, and obtain the bridge type corresponding to the bridge number;

[0024] A model building module, configured to establish a three-dimensional bridge model according to the bridge position information in the three-dimensional bridge information, the equipment position information and the bridge type;

[0025] A path-finding mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com