Defect inspection method and defect inspection device for wide-gap semiconductor substrates

A defect inspection, semiconductor technology, applied in the direction of semiconductor/solid-state device testing/measurement, optical testing flaw/defect, fluorescence/phosphorescence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0103]

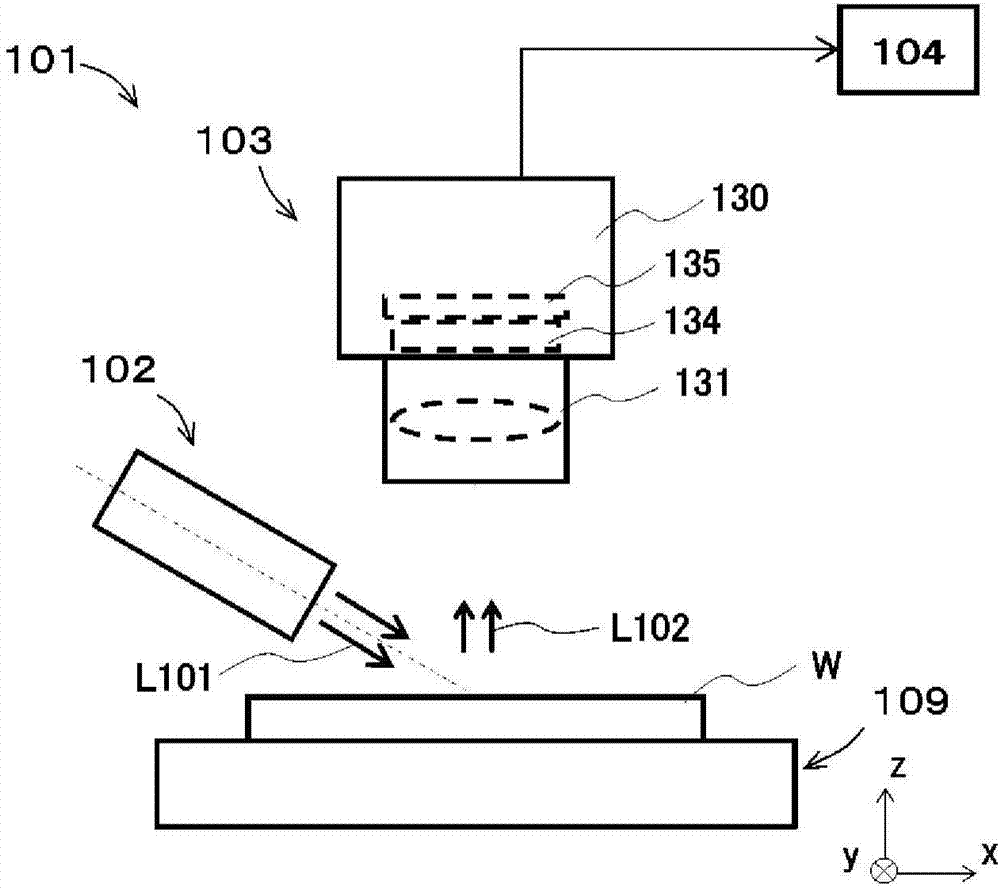

[0104] Hereinafter, the first aspect for carrying out the present invention will be described.

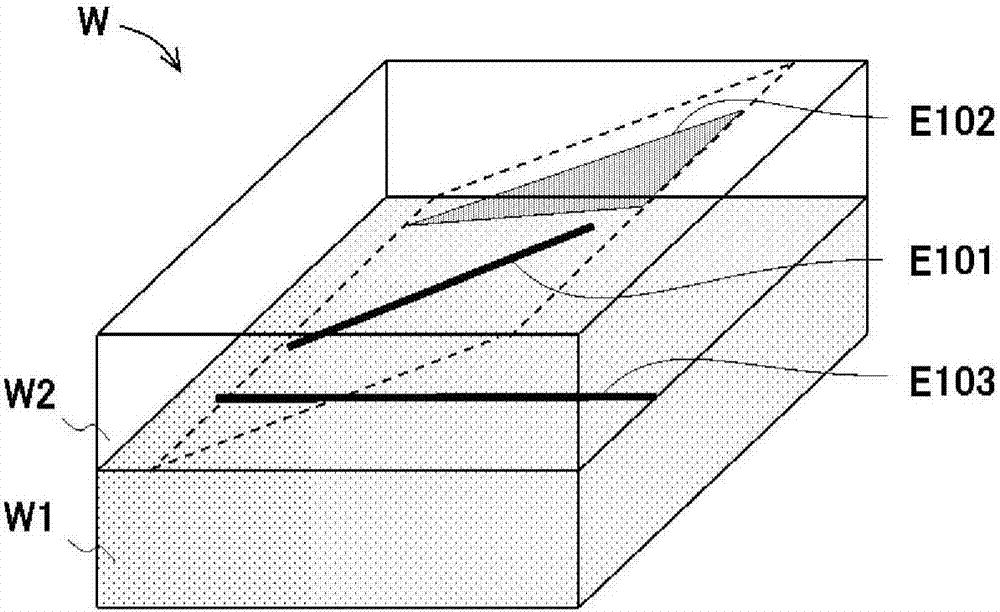

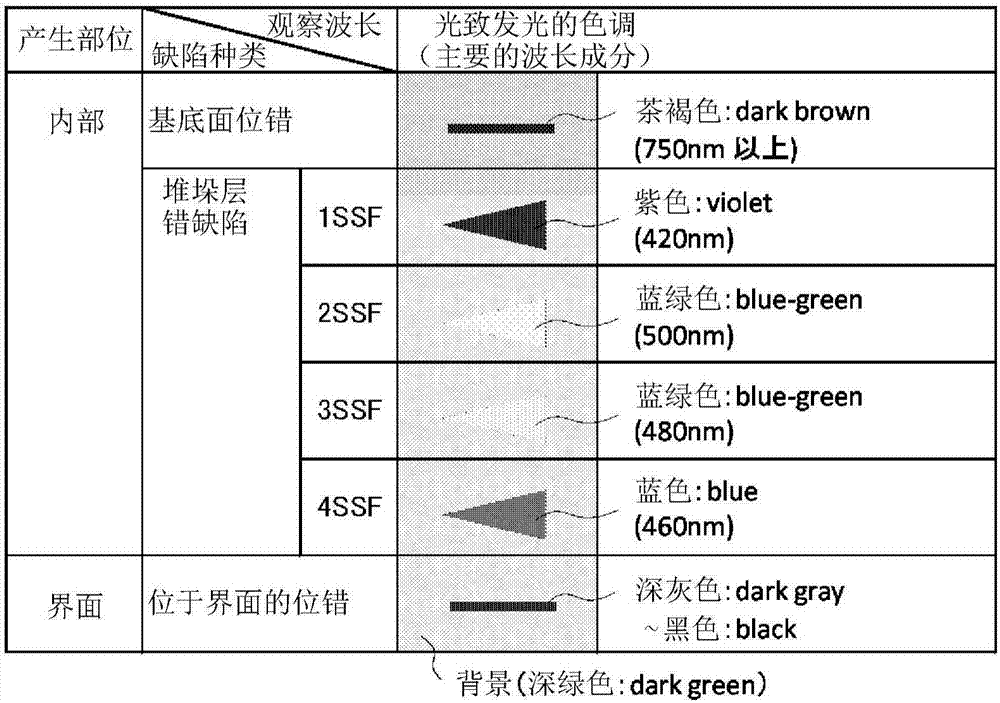

[0105] The defect inspection method of the present invention is a method of inspecting defects generated in a wide band gap semiconductor substrate,

[0106] The excitation light is irradiated toward the wide-bandgap semiconductor substrate,

[0107] The photoluminescence in the visible light region emitted by the excitation light irradiated on the wide-bandgap semiconductor substrate was photographed,

[0108] In the captured image including photoluminescence in the visible light region, the intensity of the light emitted from the portion of the wide-bandgap semiconductor substrate including the defect to be inspected is related to the intensity of the light emitted from the wide-bandgap semiconductor substrate that does not include the defect. The difference in the intensity of light emitted from the defect site to be inspected is used to inspect the defect generated in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com