Processing line of tea leaves

An assembly line and tea technology, applied in the field of assembly line, can solve the problem of low efficiency of manual tea frying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with accompanying drawing:

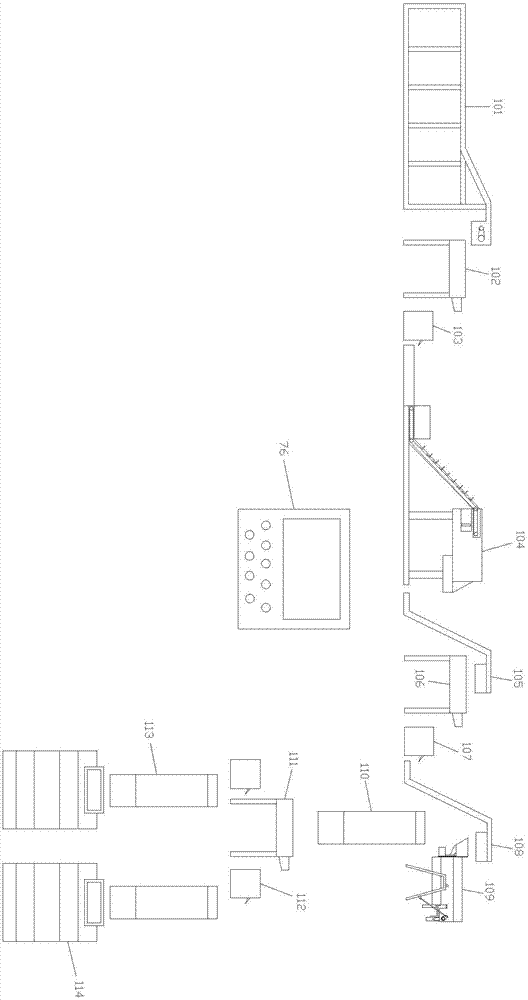

[0055] Referring to the accompanying drawings: the tea processing line is characterized in that it includes the following equipment distributed in sequence and connected to each other:

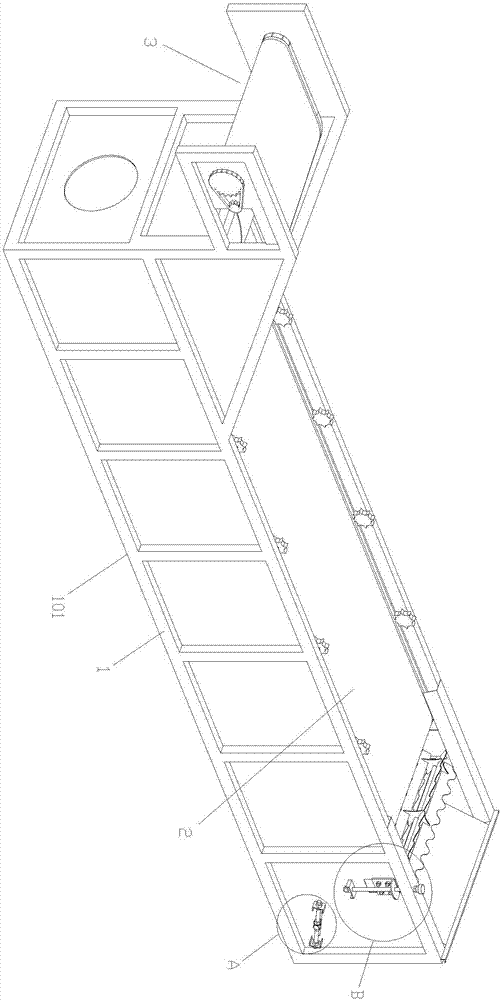

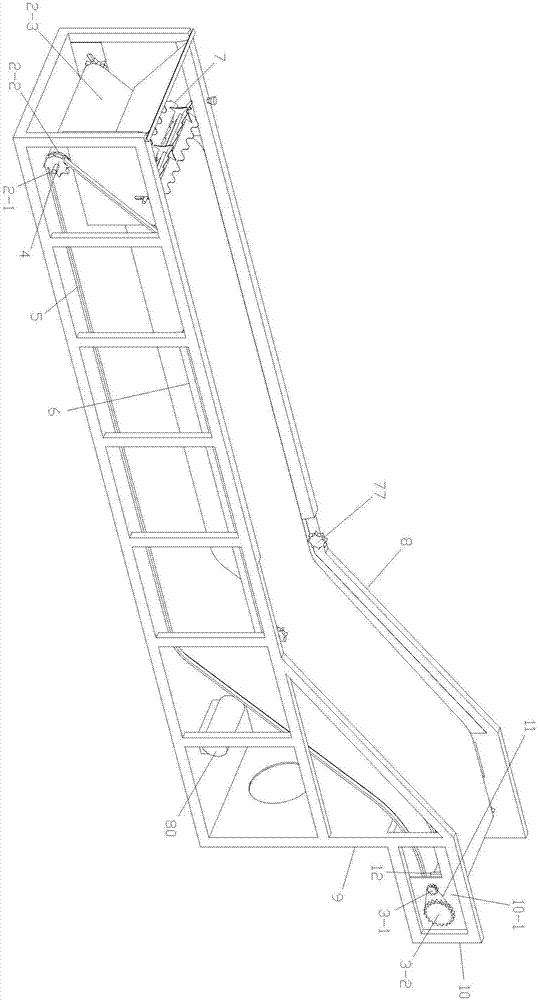

[0056] 1. Tea greening machine 101 with automatic conveying mechanism: used for drying tea leaves, and can also carry out tea transportation while drying, and convey green tea leaves to the first tea distribution machine ;

[0057] 2. The first tea splitting machine 102: used to receive the tea leaves delivered by the tea spreading machine with an automatic conveying mechanism, and split the tea leaves, and send the split tea leaves to the tea strip machine in turn ;

[0058] 3. Tea noodle machine 103: it is used to receive the tea leaves delivered by the first tea splitting machine, distribute part of the moisture and low-boiling green odor in the tea properly through the noodle, and mak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com