High-speed grinding machine special for preformed armor rods

A technology of pre-twisted wire and grinding head machine, which is applied to the parts of grinding machine tools, machine tools designed for grinding the rotating surface of workpieces, grinding machines, etc., which can solve the problems of staff injury, achieve enhanced stability, and reduce temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

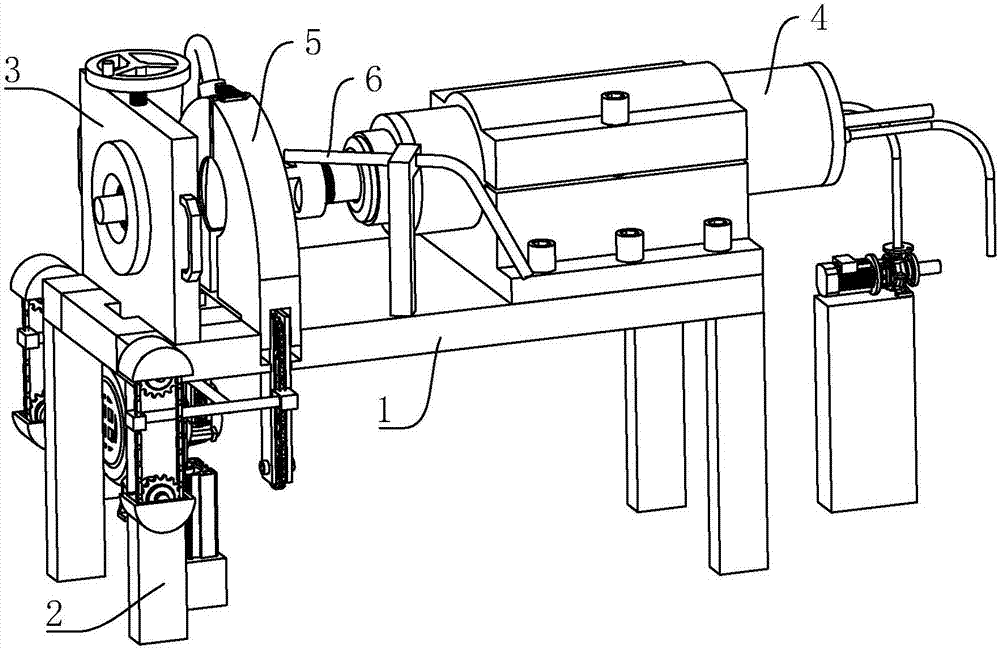

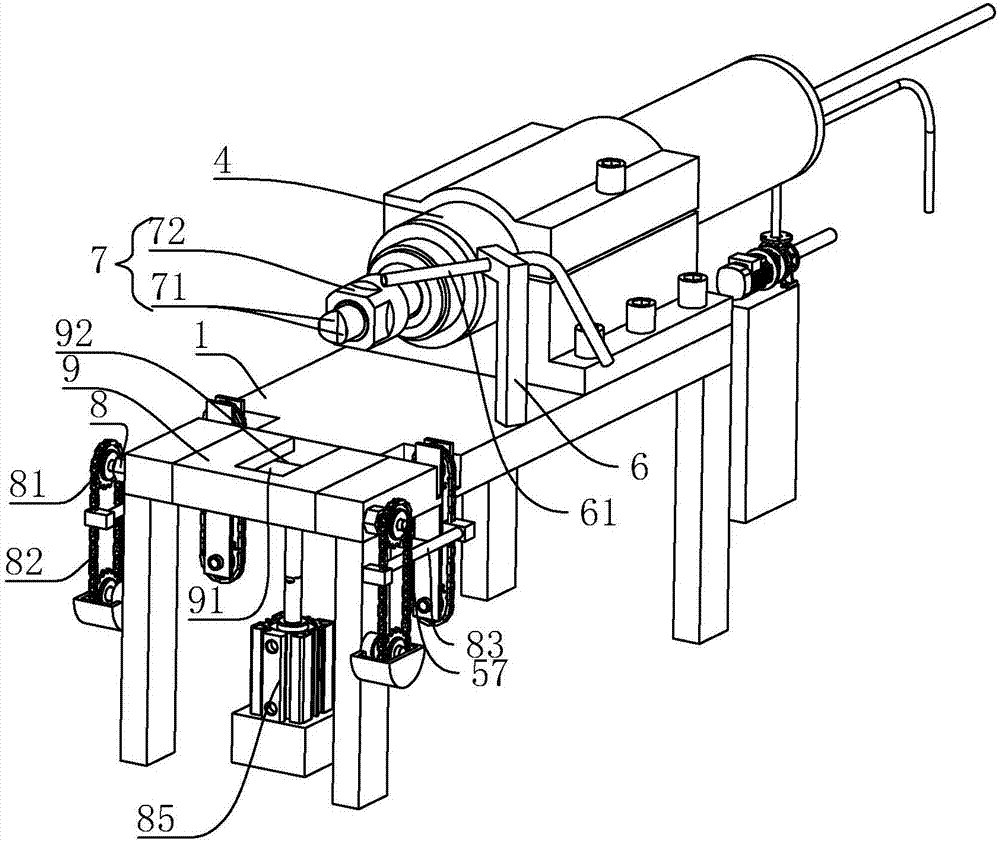

[0040] Embodiment 1: a kind of pre-twisted wire special-purpose high-speed grinder, as figure 1 As shown, it includes a rectangular support plate 1, and four supporting legs 2 are arranged under the support plate 1. The supporting plate 1 is provided with a fixing device 3 for clamping the pre-twisted wire, and the right side of the fixing device 3 is provided with a high-speed grinding machine 4 for grinding the pre-twisted wire, between the fixing device 3 and the high-speed grinding machine 4 There is a cleaning bellows 5 for cleaning the flying chips of pre-twisted wire.

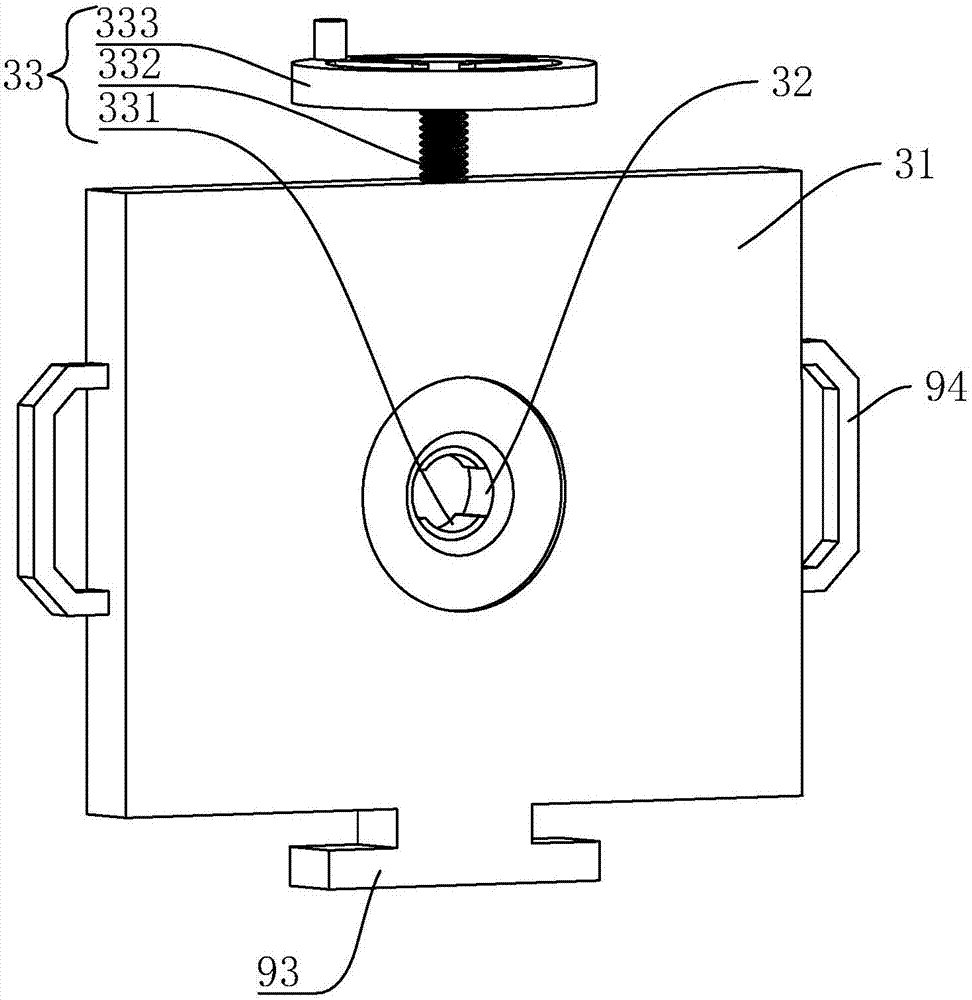

[0041] like figure 1 and 2 As shown, the fixing device 3 includes a fixing plate 31 vertically arranged on the supporting plate 1 , and the fixing plate 31 is arranged on the left side of the supporting plate 1 . The center of the fixing plate 31 is provided with a through-thread hole 32 penetrating through the fixing plate 31 , and the port of the thread-through hole 32 shrinks inwardly from the port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com