High-speed current vortex sensor

An eddy current sensor, high-speed technology, applied in the field of sensors and distance measurement, can solve the problems of inaccurate measurement results, affecting accuracy and resolution, etc., and achieve high-distance measurement, eliminate the effect of parasitic capacitance, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

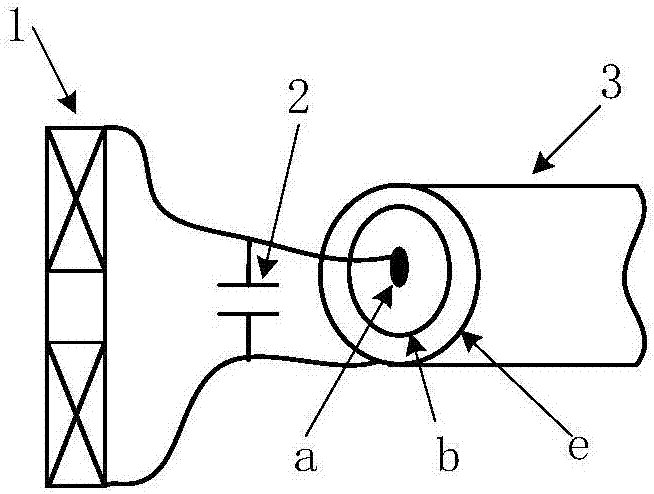

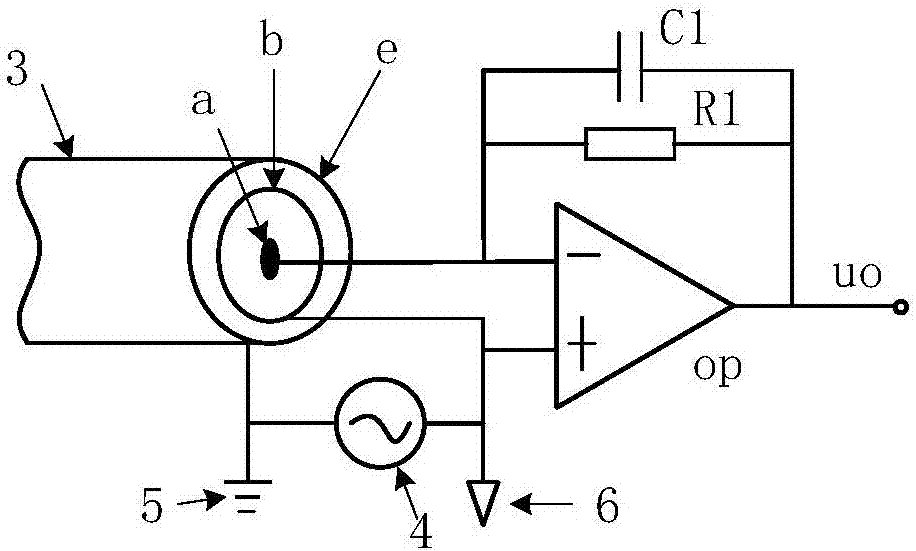

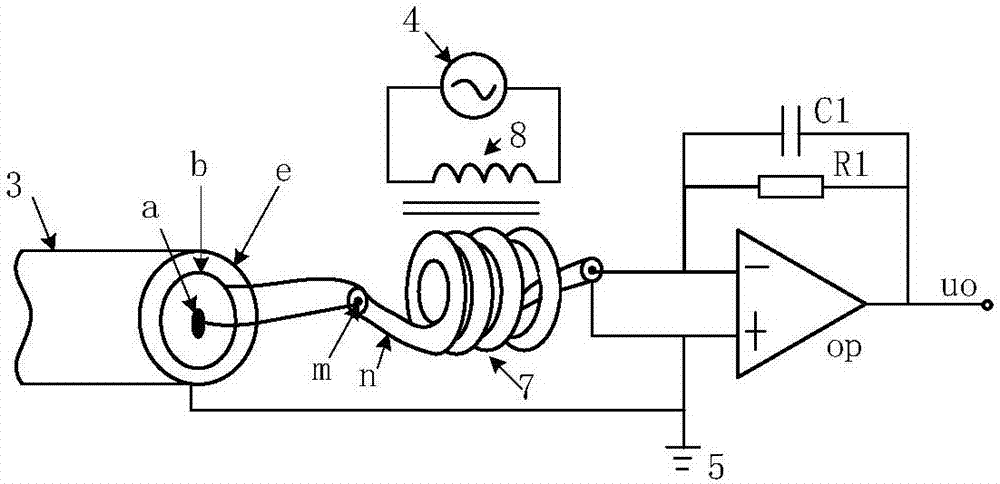

[0019] The invention belongs to the field of sensors. Specifically, the present invention relates to an eddy current sensor, in which a highly stable resonant capacitor is connected in parallel at the end of the sensor probe coil, combined with drive cable technology to eliminate the influence of parasitic capacitance between the core wire and the shielding layer, which can achieve high-speed and accurate measurement and long distance measurements.

[0020] The present invention proposes a design for an eddy current sensor. The resonant capacitor is connected in parallel to the sensor probe end, so that the series resistance is zero ohms, so as to improve the frequency response of the sensor; the triaxial cable is used for transmission, and the driving cable technology is combined to eliminate the transmission cable. The influence of parasitic capacitance to improve the accuracy and stability of sensor measurement and increase the measurement distance.

[0021] The technical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com