Method for determining strip steel width and strip steel straight deviation according to measured radial force of plate shape roller

A strip deviation and radial force technology, used in length measuring devices, metal rolling, manufacturing tools, etc., can solve the problems of inaccurate strip width, inability to provide strip center offset, etc. The effect of misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

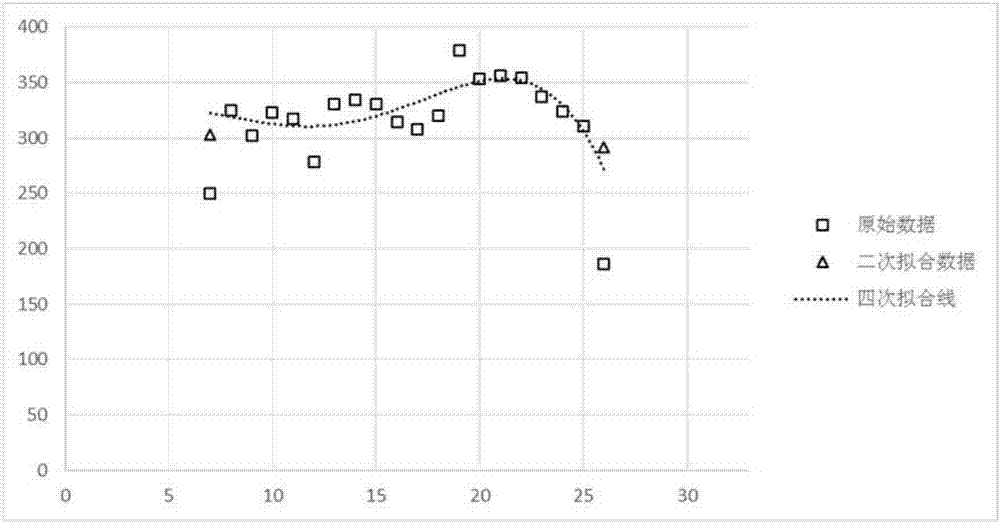

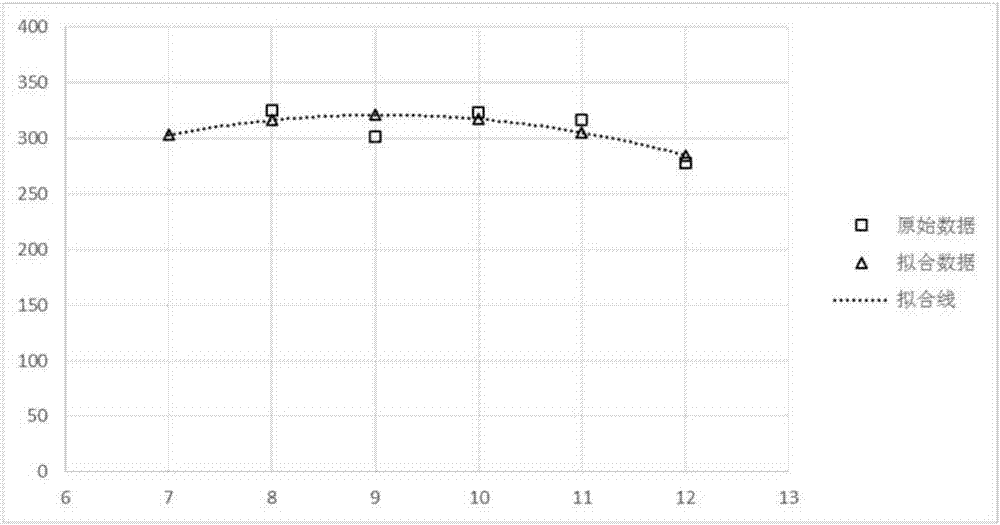

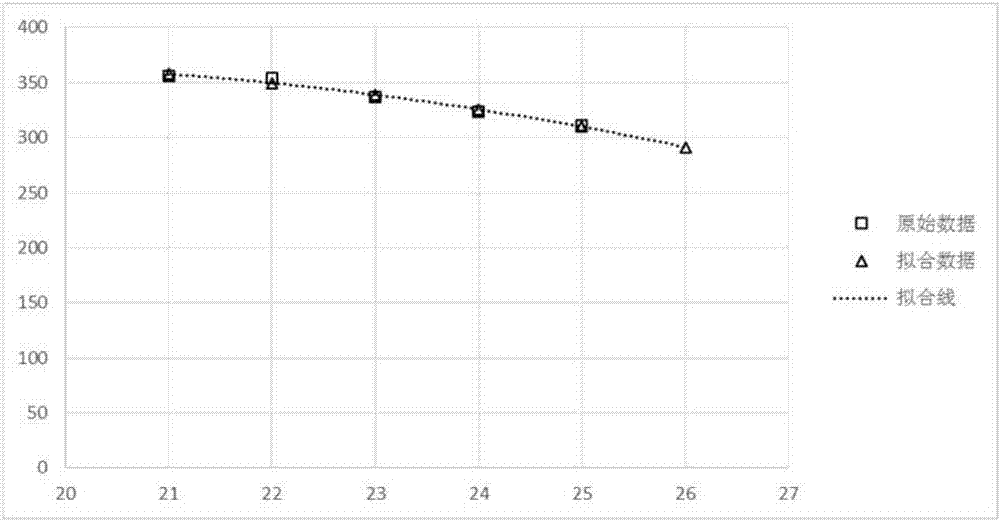

[0107] In the flatness reconstruction project of the cold rolling 1780 line tempering mill, the flatness measuring roll with the whole roll insert piezomagnetic type is used to realize the function of on-line detection of the flatness, provide the original data for the closed-loop control of the flatness, and meet the application requirements of the closed-loop control of the flatness . Due to the limited space during the equipment renovation, the skin-passing unit lacks an automatic centering device for the strip, and the deviation of the strip over a large distance often occurs. At the same time, the actual width of the strip often occurs due to the failure of the entrance strip width measuring device. The phenomenon that the strip width recorded by the system does not match.

[0108] The structure of the plate shape measurement roller adopts the whole roller block structure, and there are 33 equal-width measurement areas distributed along the axial direction of the detectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com