Automatic welding device for automobile parts

An auto parts, automatic welding technology, applied in vehicle parts, tin feeding devices, auxiliary devices, etc., can solve the problems of high cost, equipment paralysis, single structure damage, etc., and achieve the effect of low cost and structural optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0020] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below in conjunction with specific embodiments.

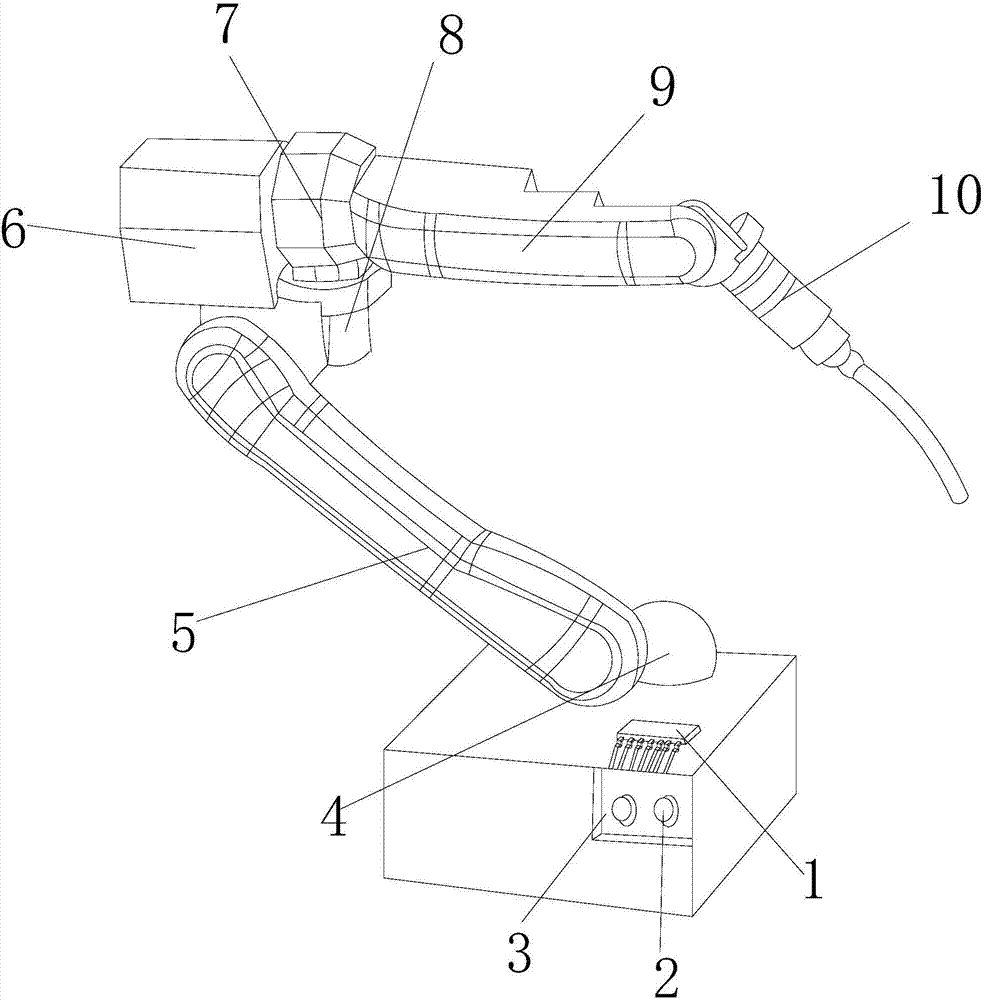

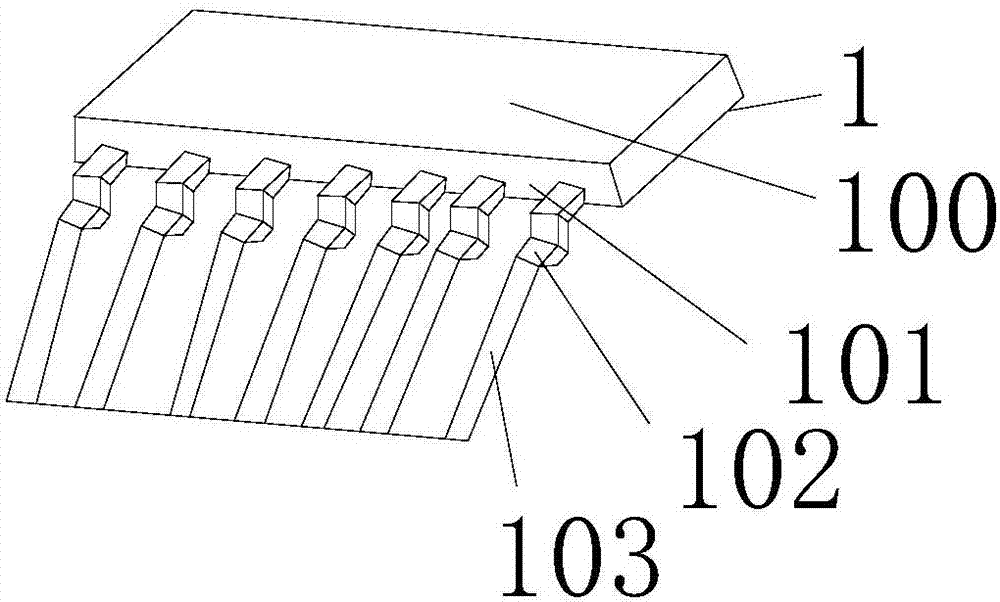

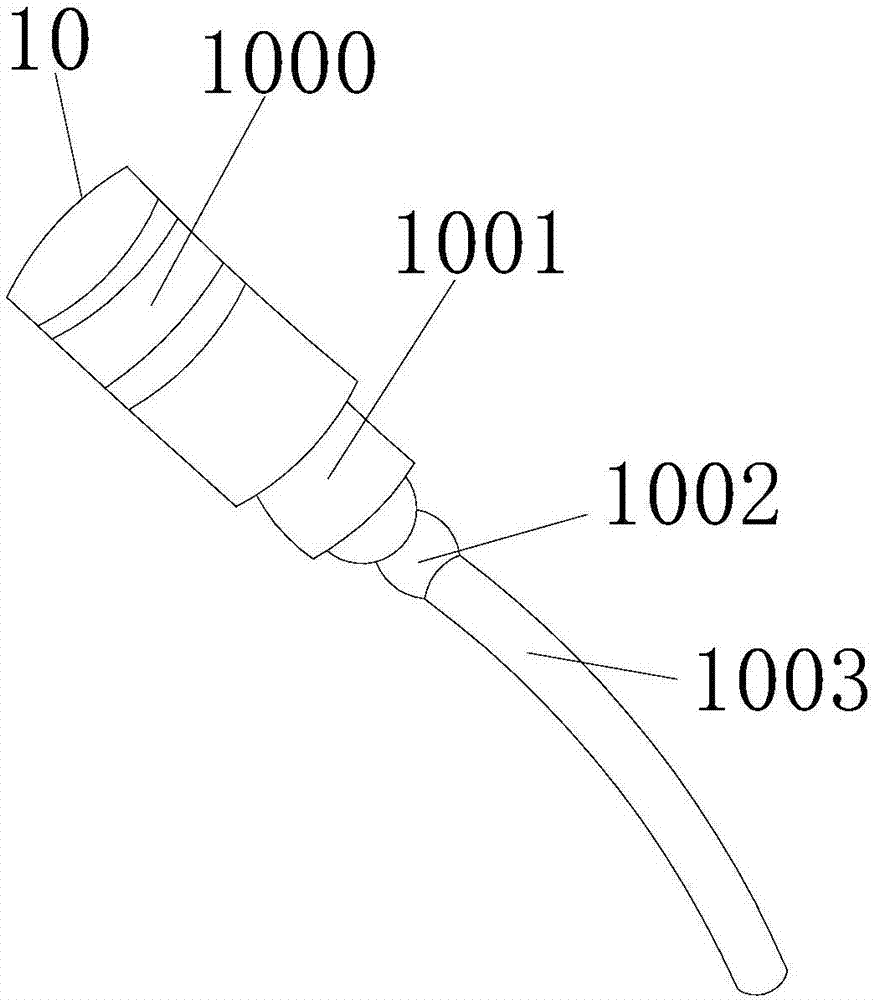

[0021] See figure 1 , figure 2 versus image 3 , The present invention provides an automatic welding device for auto parts: its structure includes: intelligent single-chip microcomputer 1, start button 2, power distribution base 3, ball and roller bearing block 4, mechanical arm 5, solder storage box 6, Welding the discharge cylinder 7, the drive roller column 8, the manipulator rod 9, the welding tin injection column 10, the start button 2 is arranged in front of the power distribution base 3, and the ball roller bearing block 4 is installed on the power distribution base 3, the power distribution base 3 and the ball roller azimuth block 4 adopt a clearance fit, and the ball roller azimuth block 4 and the robot arm 5 are an integral structure;

[0022] ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap