Welding pin taking device for bottom spot-welding

A technology of welding pins and spot bottoms, which is applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of reduced battery life, desoldering of tabs, high internal resistance, etc., and achieves a balance between welding production quality and efficiency, Solve the effect of desoldering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Further description will be made below in conjunction with drawings and embodiments.

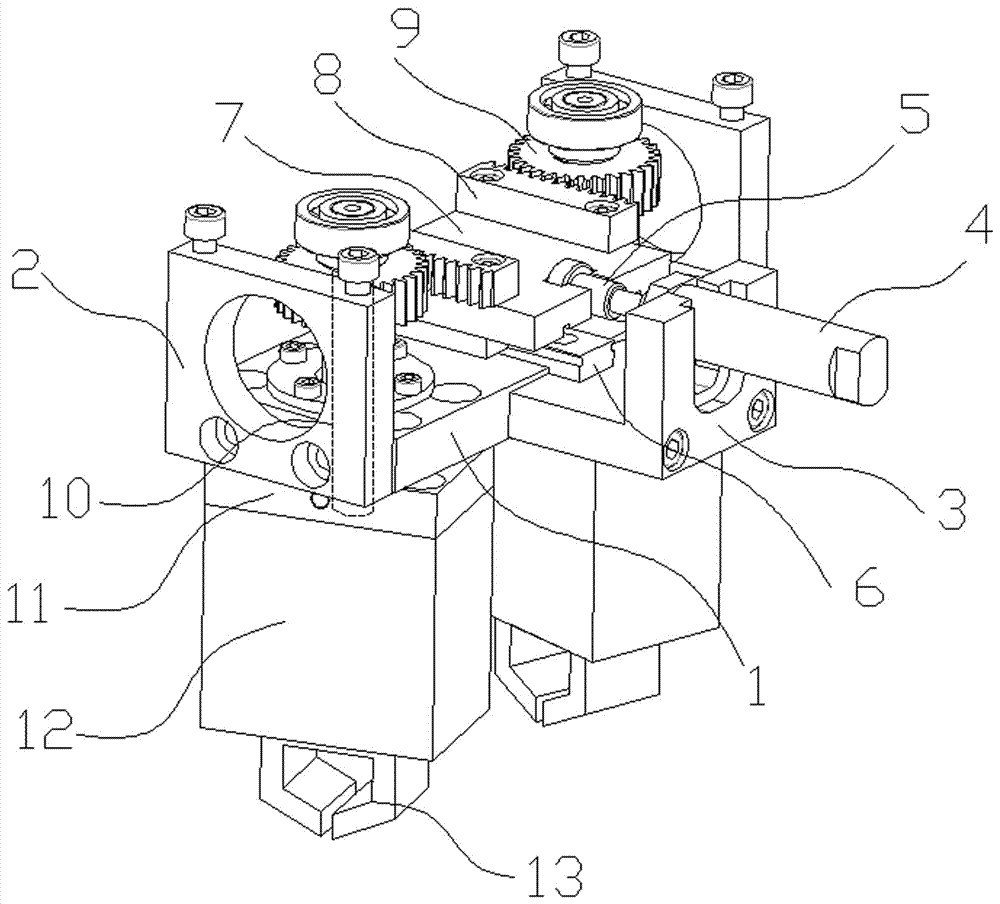

[0009] figure 1 As shown: a device for spot bottom welding and taking welding needles includes a bottom plate 1, a side plate 2, a cylinder support seat 3, a swing cylinder 4, a cylinder connector 5, a linear track 6, a track connecting plate 7, a rack 8, a gear 9, Rotating shaft 10, pneumatic finger connecting seat 11, pneumatic finger 12, clamp 13. The machine base consists of the bottom plate 1 and the side plates 2 on both sides of the bottom plate 1. The machine base is connected to the lithium battery production line rack in a state of lifting up and down after the cylinder is taken out. The cylinder support seat 3 is connected to the bottom plate 1, and the swing cylinder 4 is supported on the cylinder. On the support seat 3, the linear track 6 is arranged on the bottom plate 1, and the track connecting plate 7 is arranged on the linear track 6 and is connected to the swing cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com