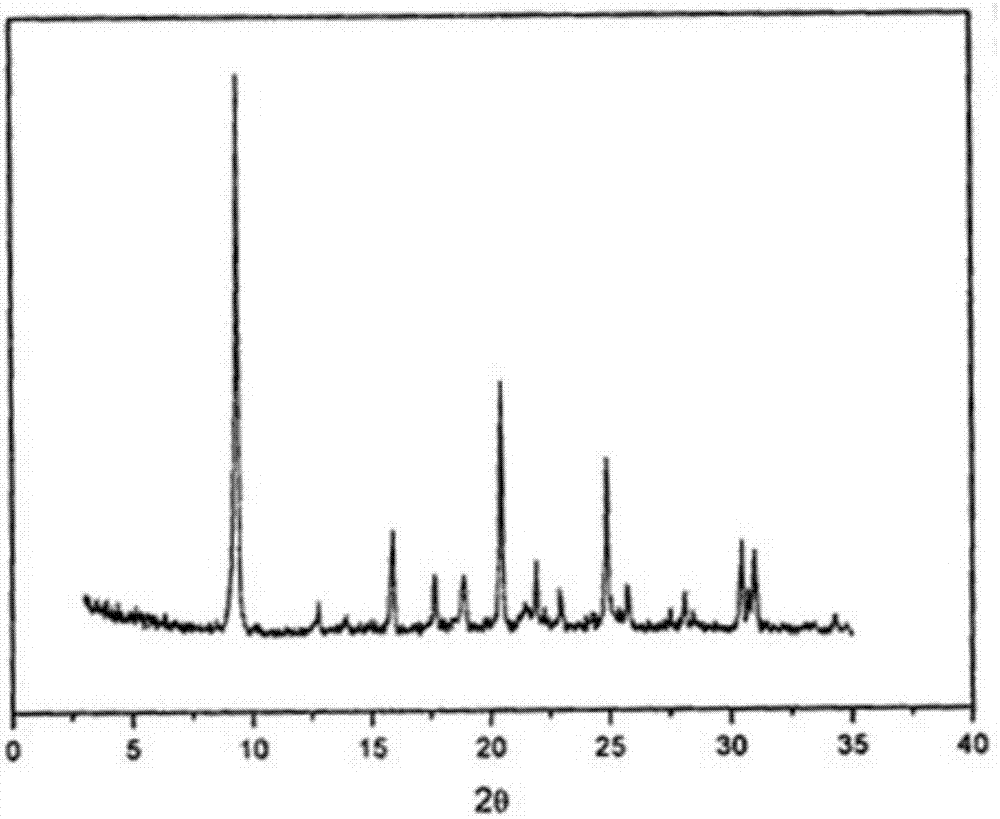

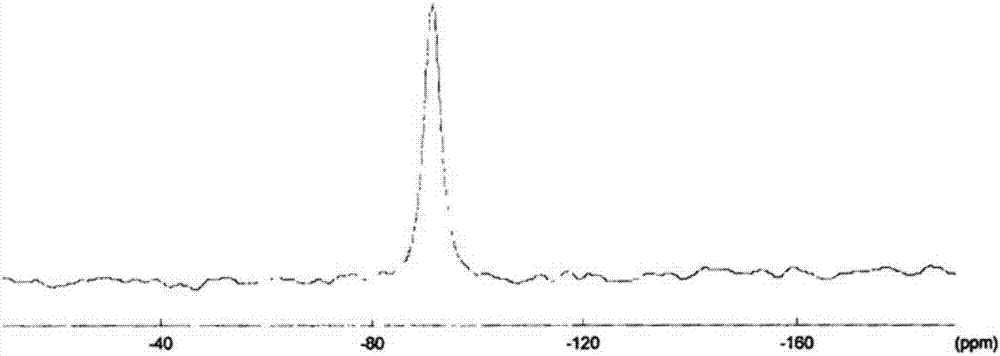

Synthesis method of SAPO-34 molecular sieve

A technology of SAPO-34 and synthesis method, which is applied in the field of synthesizing SAPO-34 molecular sieve, can solve the problems of poor solubility of silicon source, uneven distribution of silicon components, unstable catalytic performance of SAPO-34 molecular sieve, etc., and achieve long life and change The effect of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] First preheat 0.25mL silicon source with 1.75mL phosphoric acid at 200°C for 3-4 hours and then cool. At 20°C, dissolve 1.74g of pseudo-boehmite powder with 10mL of deionized water, then add dropwise the mixture of phosphorus source and silicon source, 4.65mL of triethylamine, stir well, transfer to a stainless steel reaction kettle for crystallization at 200°C 1 to 2 days, and then according to the conventional molecular sieve post-treatment method, cooling, washing, drying, and collecting the product.

Embodiment 2

[0020] First preheat 0.25mL silicon source with 1.75mL phosphoric acid at 200°C for 3-4 hours and then cool. At 20°C, dissolve 1.74g of pseudo-boehmite powder with 10mL of deionized water, then add dropwise the mixture of phosphorus source and silicon source, 4.65mL of triethylamine, stir well, transfer to a stainless steel reaction kettle for crystallization at 180°C 1 to 2 days, and then according to the conventional molecular sieve post-treatment method, cooling, washing, drying, and collecting the product.

Embodiment 3

[0022] First preheat 0.25mL silicon source with 1.75mL phosphoric acid at 200°C for 3-4 hours and then cool. At 20°C, dissolve 1.74g of pseudo-boehmite powder with 10mL of deionized water, then add dropwise the mixture of phosphorus source and silicon source, 4.65mL of triethylamine, stir well, transfer to a stainless steel reaction kettle for crystallization at 170°C 1 to 2 days, and then according to the conventional molecular sieve post-treatment method, cooling, washing, drying, and collecting the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com