Preparation method of high-viscosity attapulgite-based inorganic gel

An attapulgite and inorganic gel technology, applied in inorganic chemistry, chemical instruments and methods, silicon compounds, etc., can solve problems such as no research reports, and achieve the effects of increasing viscosity, green preparation process, and high suspension stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

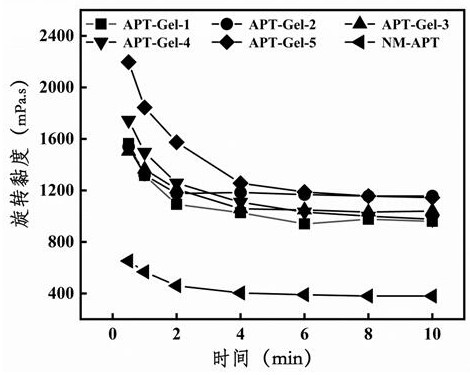

Embodiment 1

[0017] (1) 100 kg of natural attapulgite raw ore is crushed to 100 mesh, and the rollers are evenly dispersed to 3 m 3 Sulfuric acid aqueous solution (pH = 3), mechanically stirred for 6 hours to obtain a suspension, followed by three-stage cyclone classification treatment and ultrasonic treatment (ultrasonic treatment power 20KHZ, time 3min) to obtain a suspension after rod crystal beam dissociation treatment ;

[0018] (2) Add 0.5 kg magnesium sulfate solid powder to the suspension after rod crystal beam dissociation treatment, and mechanically stir for 4 hours to obtain a modified suspension;

[0019] (3) Filter the modified suspension through a plate and frame press to obtain a filter cake with a water content of 40%, and then roll the filter cake into 1mm thin slices, and perform a strong drying treatment (drying temperature is 90°C) to obtain an inorganic gel product. labeled APT-Gel-1;

[0020] (4) Disperse 7 g of APT-Gel-1 sample in 93 mL of water, stir at 11,000 rpm...

Embodiment 2

[0022] (1) After crushing 200 kg of natural attapulgite raw ore to 50 mesh and rolling it 3 times, it is evenly dispersed to 3 m 3 Hydrochloric acid aqueous solution (pH = 3), mechanically stirred and reacted for 2 hours to obtain a suspension; then the suspension was subjected to three-stage cyclone classification and ultrasonic treatment (ultrasonic treatment power 20KHZ, treatment time 6min), and rod crystal beam dissociation The treated suspension; (2) Add 2 kg of sodium dihydrogen phosphate solid powder to the suspension after rod crystal beam dissociation treatment, and mechanically stir for 4 hours to obtain a modified suspension;

[0023] (3) The modified suspension is filtered through plate and frame to obtain a filter cake with a water content of 40%, and then the filter cake is rolled into 1mm thin slices, and the inorganic gel product is obtained through strong drying (drying temperature is 100°C). Labeled APT-Gel-2;

[0024] (4) Take 7g of APT-Gel-2 sample and di...

Embodiment 3

[0026] (1) After crushing 200 kg of natural attapulgite raw ore to 100 mesh and rolling it 3 times, it is evenly dispersed to 3 m 3 Phosphoric acid aqueous solution (pH = 3.5), mechanically stirred for 6 hours to obtain a suspension; then the suspension was subjected to three-stage cyclone classification treatment and ultrasonic treatment (ultrasonic treatment power 20KHZ, treatment time 9min), to obtain rod crystal beam dissociation The treated suspension; (2) Add 10 kg of ammonium dihydrogen phosphate solid powder to the suspension after rod crystal beam dissociation treatment, and mechanically stir for 4 hours to obtain a modified suspension;

[0027] (3) The modified suspension is centrifuged to obtain a filter cake with a water content of 40%, and then the filter cake is rolled into a 2mm sheet, and the inorganic gel product is obtained after a strong drying treatment (drying temperature is 110°C), which is marked as APT-Gel-3;

[0028] (4) Disperse 7 g of APT-Gel-3 samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com