High-performance anti-tracking addition type liquid silicon rubber composition and preparation method thereof

A liquid silicone rubber and tracking technology, which is applied in the field of silicone rubber high-voltage insulating materials, can solve the problem of reducing the mechanical properties of addition-type liquid silicone rubber, the polarity of inorganic anti-tracking agents, and damage to the hydrophobicity of addition-type liquid silicone rubber. Anti-fouling performance and other issues, to achieve the effect of improving tracking resistance, improving hydrophobic performance, and small electric corrosion loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

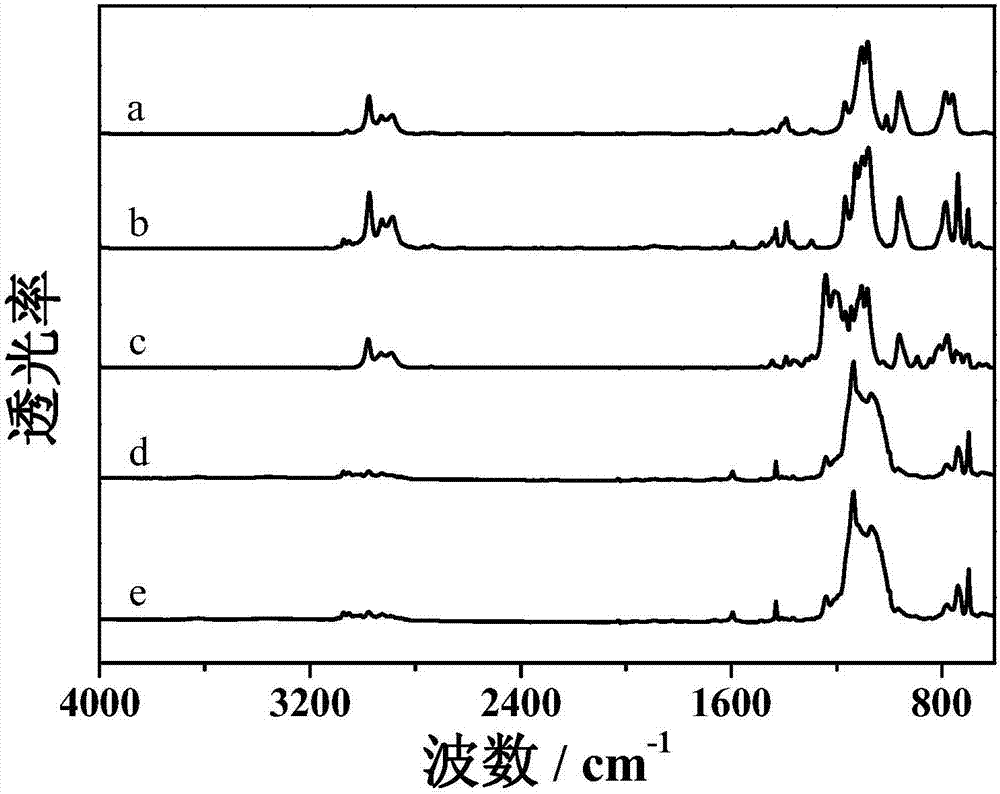

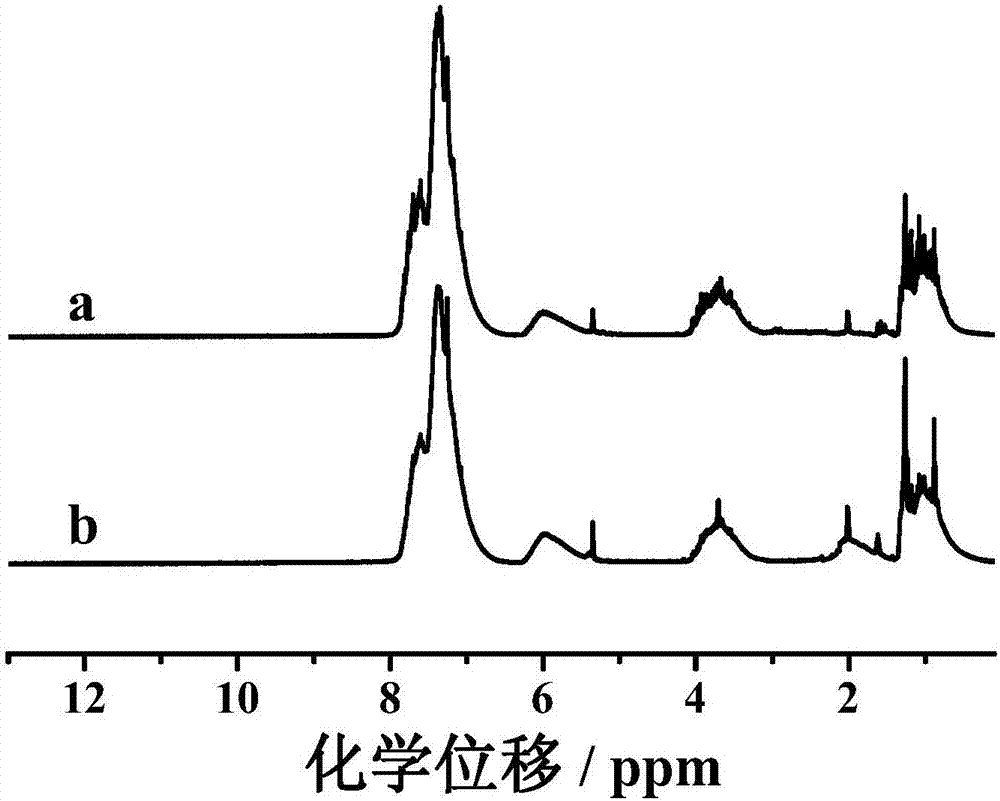

Embodiment 1

[0036] A mixed solution of 30 g of ethanol, 0.4 g of hydrochloric acid and 5.8 g of deionized water was added to a 150 mL four-neck flask equipped with a reflux device, a mechanical stirrer and a constant pressure dropping funnel, and 1.5 g of tridecafluorooctyl Alkyltriethoxysilane, 3.8g of vinyltriethoxysilane and 24.0g of phenyltriethoxysilane were dissolved in 20g of ethanol solvent, and added dropwise into a four-necked flask. Under the condition of mechanical stirring, the temperature was raised to 70°C for 3 hours, and then the temperature was raised to 120°C for 24 hours. Finally, ethanol was distilled off under reduced pressure to obtain fluorine-containing organic-inorganic hybrid low-melting glass 1 (FOILMG1)

[0037] 100 parts by mass of vinyl silicone oil (viscosity at 25°C is 25200mPa·s, vinyl content is 0.25mol%), 40 parts by mass of fumed silica (specific surface area is 260m 3 / g), 6.8 parts by mass of hexamethyldisilazane were mixed in a vacuum kneader, knead...

Embodiment 2

[0040] A mixed solution of 26g of ethanol, 0.3g of hydrochloric acid and 5.4g of deionized water was added to a 150mL four-neck flask equipped with a reflux device, a mechanical stirrer and a constant pressure dropping funnel, and 2.9g of tridecafluorooctyl Alkyltriethoxysilane, 2.1 g of vinyltriethoxysilane and 14.0 g of phenyltriethoxysilane were dissolved in 20 g of ethanol solvent, and added dropwise into a four-necked flask. Under the condition of mechanical stirring, the temperature was raised to 50° C. for 3 hours, and then the temperature was raised to 150° C. for 24 hours. Finally, ethanol was distilled off under reduced pressure to obtain fluorine-containing organic-inorganic hybrid low-melting glass 2 (FOILMG2).

[0041] 100 parts by mass of vinyl silicone oil (viscosity at 25°C is 25200mPa·s, vinyl content is 0.25mol%), 40 parts by mass of fumed silica (specific surface area is 260m 3 / g), 6.8 parts by mass of hexamethyldisilazane were mixed in a vacuum kneader, kn...

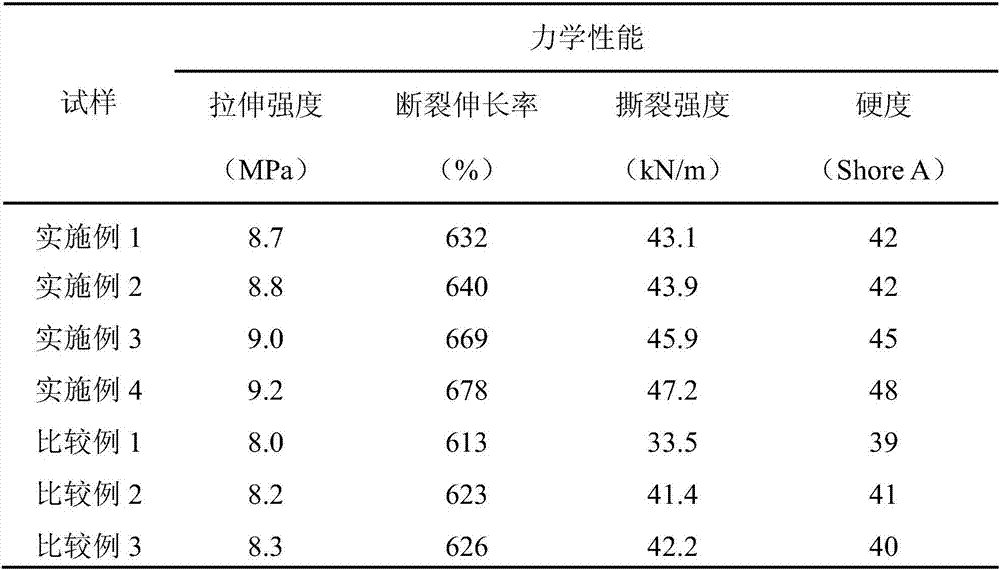

Embodiment 3

[0046] 100 parts by mass of vinyl silicone oil (viscosity at 25°C is 25200mPa·s, vinyl content is 0.25mol%), 40 parts by mass of fumed silica (specific surface area is 260m 3 / g), 6.8 parts by mass of hexamethyldisilazane were mixed in a vacuum kneader, kneaded at 30°C for 4h, heated to a material temperature of 170°C and continued to knead for 1h, then vacuumized and kneaded for 2h, cooled and passed Grinding on a three-roll machine to obtain the addition-type liquid silicone rubber base material.

[0047] In the above-mentioned 100 parts by mass of base rubber, add 2 parts by mass of FOILMG2, 3 parts by mass of ureido vinyl MQ silicone resin (U-MQ), 1.82 parts by mass of hydrogen-containing silicone oil (hydrogen content is 0.75wt%), 0.03 Mass parts of 1-ethynyl-1-cyclohexanol and 0.25 mass parts of divinyltetramethyldisiloxane complex of chloroplatinic acid (platinum content is 3000ppm), stirred evenly at 30°C, at 120°C The lower mold was pressed for 10 minutes to make a 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com