Bailey truss double-layer bidirectional arrangement high-supported formwork construction method

A construction method and beret technology, which is applied in the direction of erecting/assembling bridges, bridges, buildings, etc., can solve the problems of inability to meet the bearing capacity and stability, heavy load, height, etc., to solve the problems of insufficient bearing capacity and stability, The effect of large span and high erection height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

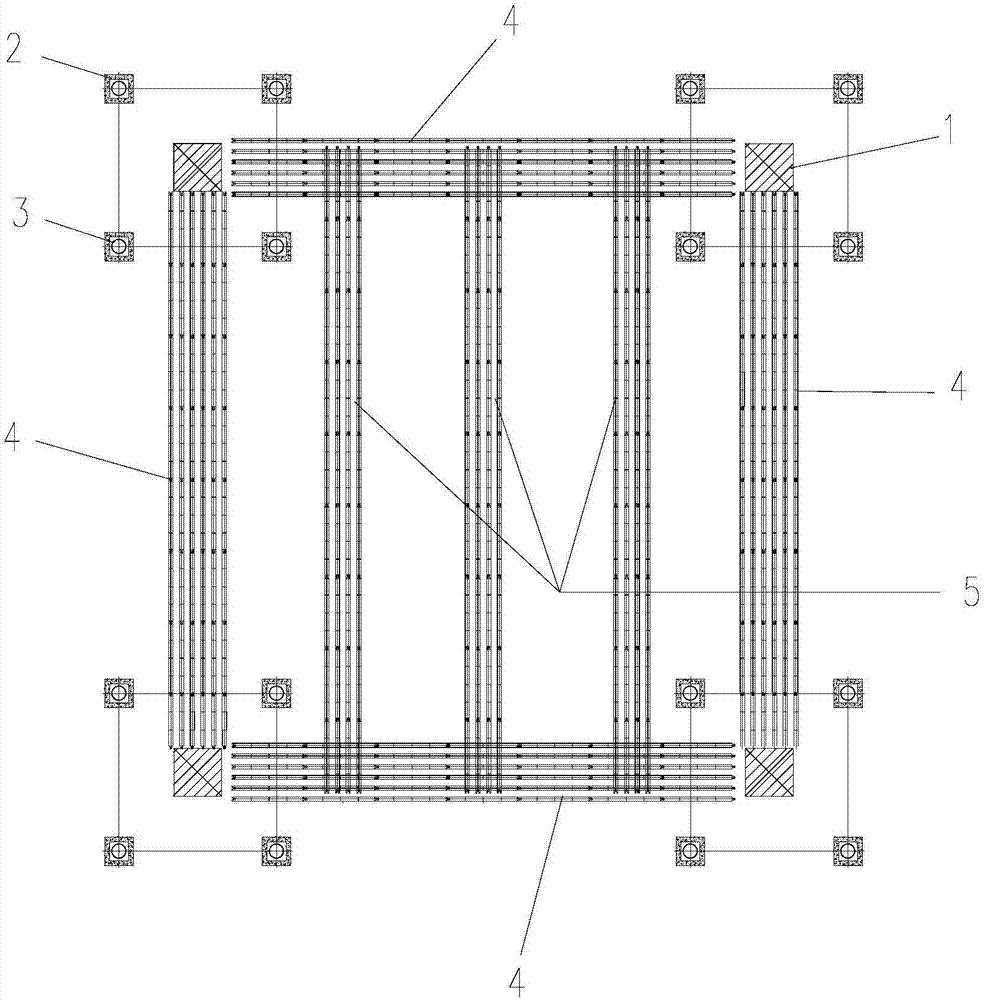

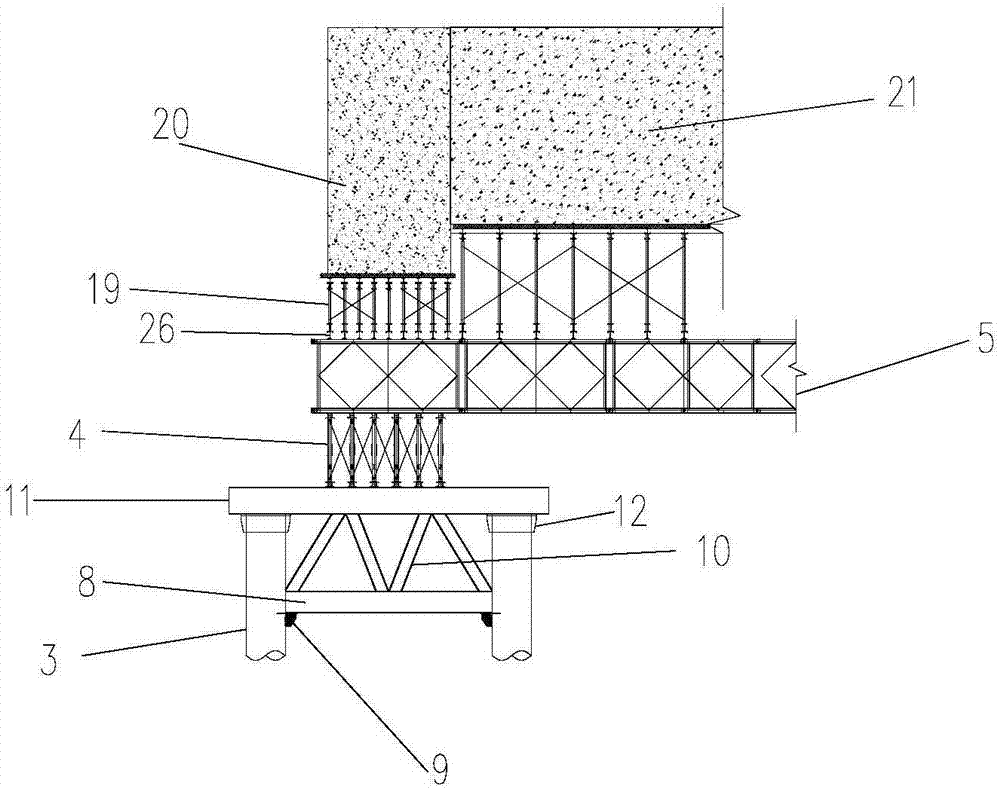

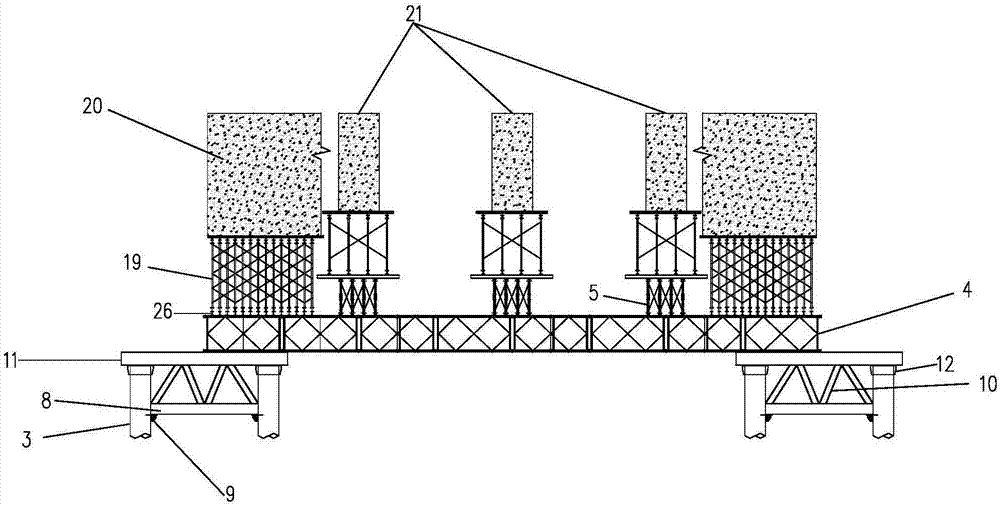

[0045] Such as Figure 1 to Figure 11 ,

[0046] Step 1. Carry out the construction of the lattice type steel pipe column;

[0047] Level the site, carry out independent foundation 2 lofting, and construct lattice steel pipe columns. Each group of lattice steel pipe columns includes a reinforced concrete column 1 and four steel pipe columns 3. The reinforced concrete independent foundation 2 at the bottom of each steel pipe is placed and pre-embedded Part steel plate 14, see Fig. 4, embedded part steel plate 14 is welded by threaded steel bar 13 and steel plate 14 perforated plugs;

[0048] Weld the standardized flange 16 to the steel plate 14 of the embedded part, and at the same time use a fixed steel block 15 with a thickness of 10 mm to 20 mm to fix the steel pipe column 3 and the steel plate 14 of the embedded part, see Figure 5, the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com