Laminated screw disc heat exchanger

A stacked heat exchanger technology, applied in the direction of indirect heat exchangers, heat exchanger types, laminated components, etc., can solve the problem that small spiral plate heat exchangers cannot be processed, which affects the continuous technological improvement and development of equipment, and processing technology Complicated problems, to achieve the effect of improving heat transfer coefficient and heat transfer efficiency, shortening heat transfer time, and simplifying processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

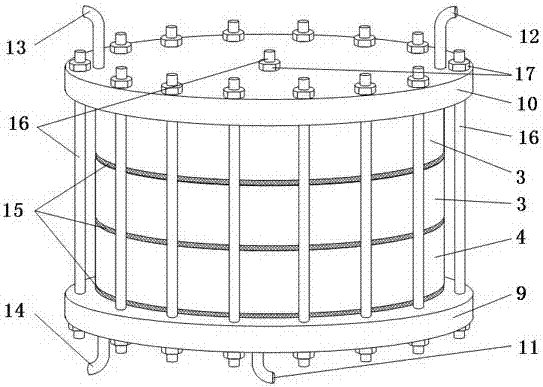

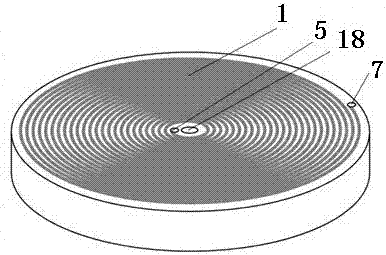

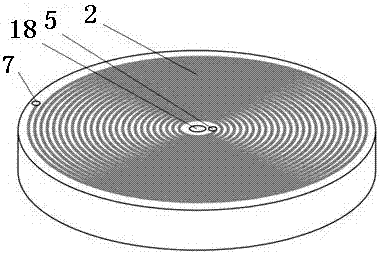

[0043] Furthermore, please also refer to Figure 1 to Figure 9, as a specific embodiment of the laminated spiral heat exchanger provided by the present invention, the sealing fastener includes an upper clamping plate 10 and a lower clamping plate 9, between the upper clamping plate 10 and the double-sided spiral plate 3 Between, between the double-sided screw disk 3 and the double-sided screw disk 3, and between the double-sided screw disk 3 and the lower splint 9, flexible sealing backing plates 15 for sealing are respectively provided, passing through the The upper clamping plate 10, the double-sided screw disk 3, the lower clamping plate 9, the central hole 18 of each of the flexible sealing backing plates 15, and the multiple pairs of bolt pairs of the upper clamping plate 10 and the edge holes of the lower clamping plate 9 are fastened and connected, each The flexible sealing backing plate 15 is respectively provided with communication holes for cold fluid or hot fluid to...

specific Embodiment approach

[0044] Further, see figure 1 , as a specific embodiment of the laminated spiral heat exchanger provided by the present invention, the flexible sealing backing plate 15 is made of high temperature resistant polytetrafluoroethylene material.

[0045] Further, see Figure 6 to Figure 9 , as a specific embodiment of the laminated spiral heat exchanger provided by the present invention, when multiple double-sided spiral disks 3 are stacked, the first spiral groove 1 and the first spiral groove 1 of each double-sided spiral disk 3 The ends of the second spiral groove 2 are respectively provided with vertical communication holes so that the stacked double-sided spiral disks 3 are connected in series up and down, or each double-sided spiral disk 3 corresponds to the side of the first spiral groove 1 and the end of the second spiral groove 2 Horizontal communication holes are provided respectively, and the stacked double-sided spiral discs 3 are connected in parallel through external ...

Embodiment 1

[0053] Embodiment 1: Four-layer spiral heat exchanger connected in series.

[0054] The hot fluid (gray arrow) from the heating unit enters the bottom layer (named the first layer for ease of description) from the first feed pipe 11 located in the middle of the lower clamping plate 9 through the fourth communication hole 20 of the flexible sealing backing plate 15 , the above are arranged in order, and the following embodiments are the same) The second helical groove 2 of the double-sided spiral disk 3 flows from the center to the edge along the second helical groove 2, and in the flow process, it is connected with the first helical groove on the top The cold fluid flowing in reverse direction in 1 performs heat exchange, and then enters the second spiral groove 2 of the second layer of double-sided spiral disk 3 through the U-shaped connecting pipe through the horizontal communication hole 8 on the second side of the second double-sided spiral disk 3 , flows from the edge to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com